Intelligent boundary detection provides fast, precise measurement of round holes, rectangular holes, and slots, ensuring high-quality and high-accuracy data capture.

FreeScan Trak ProW

Wireless 3D Dynamic Tracking & Scanning System with Expanded Range

- Marker-Free & Wireless Scanning

- Max. 8.6 m Tracking Distance & 206.7 m³ Tracking Volume

- Integrated Video Photogrammetry (VPG)

- Compatible with FreeProbe (Optional)

- Verified Accuracy (VDI/VDE 2634 & ISO 10360)

Track Smarter, Expand Further

No Markers Needed

The FreeTrak W dynamically tracks the TE25W scanner using its tracking targets, eliminating the need to manually place markers on the scanned object.

Fast Paced Scanning

FreeScan Trak ProW enables fast paced and smooth scanning tasks with a scan speed up to 5,500,000 points/s.

Proven Accuracy

Delivering high-precision scanning results compliant with VDI/VDE 2634 and ISO 10360

3 Modes for Versatile Applications

The TE25W features 3 scanning modes: High-speed scanning, Detailed scanning, Deep pockets scanning.

Ultra-Wide Measuring Range

FreeScan Trak ProW features a groundbreaking design with an ultra-long 8.6 m tracking distance and widely expands the single-station tracking volume to 206.7 m³, significantly reducing the need for leapfrog* during large-scale object scanning.

*(1) Leapfrog: Refers to the technique of relocating the measuring device to extend its working volume. This involves measuring reference geometries (artifacts) in one position, then repositioning the device and measuring the same reference geometries again. These reference points establish a link between the new device position and the original coordinate system, allowing measurements to be consistently reported in the same reference frame.

Wireless Scanning Wherever You Go

FreeScan Trak ProW delivers fast, wireless scanning anywhere. Its cable-free design enables real-time data transfer, with power bank support for unrestricted mobility. An integrated screen ensures seamless operation.

- Built-In Computing Modules

- Integrated Wireless Modules

- Flexible Power Supply

- Real-Time Display Screen

No Markers Needed,

Fast Paced Scanning

FreeTrak W enables real-time TE25W scanner recognition and positioning, eliminating the need for reference markers, which enhances scanning efficiency and streamlines the workflow, while ensuring rapid data acquisition with a scanning speed of up to 5,500,000 points per second.

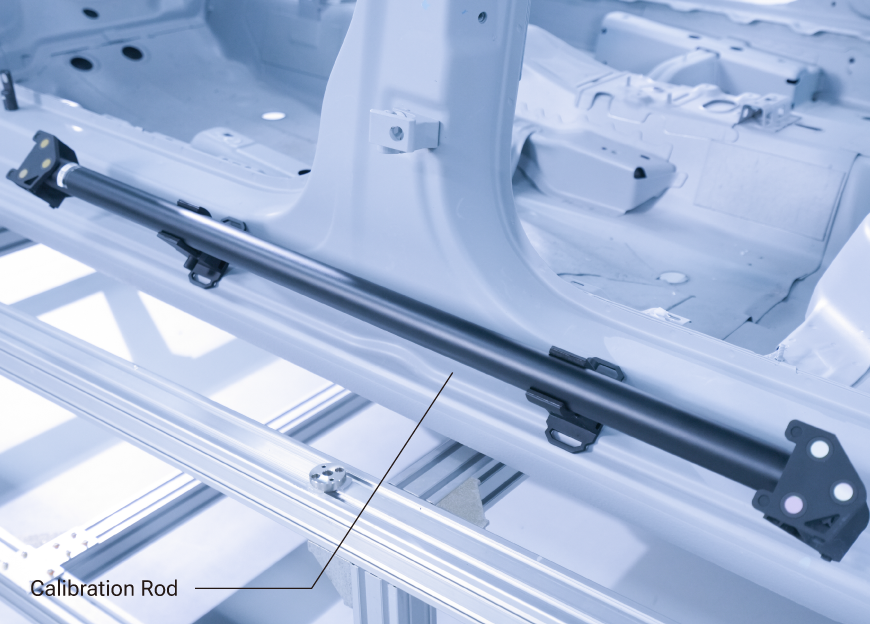

Video Photogrammetry (VPG)

FreeScan Trak ProW features SHINING 3D’s patented video-based photogrammetry, which eliminates the need for coded markers. By integrating photogrammetry technology with a calibration rod, it enables real-time marker verification through video capture. This ensures consistent volumetric accuracy and streamlines the setup process for efficient large-object scanning.

Certified Metrology Accuracy

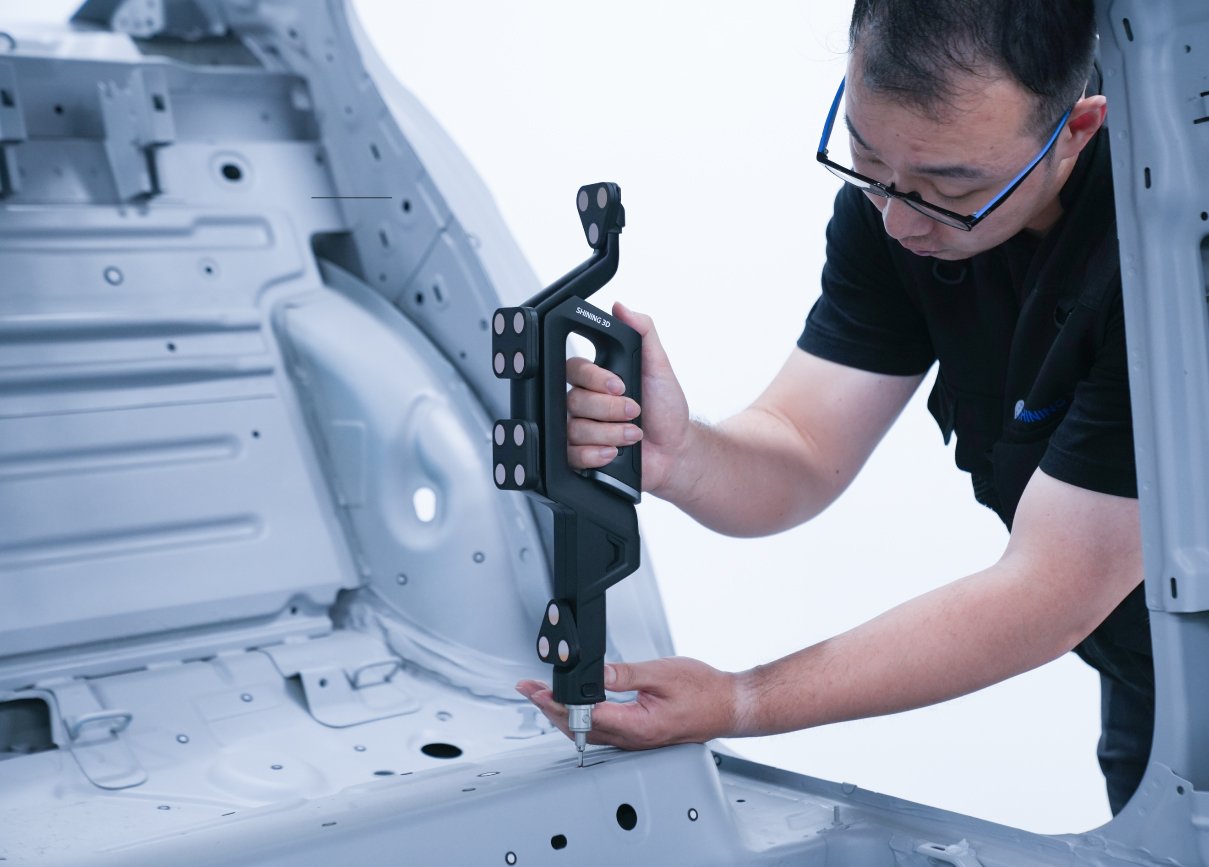

FreeProbe Series (Optional)

Designed for fast, shop-floor measurements and inspections, FreeProbe line-up captures precise geometric data without generating mesh. It is ideal for hidden areas that scanners cannot reach, ensuring data acquisition with pinpoint accuracy.

Metrology Pro Kit

Ideal for 3D dynamic tracking and scanning systems, Metrology Pro Kit supports stable and precise tracking with different leapfrog marker options for scanning large and complex objects.

Our Support Coverage

INSPECT ON THE MOVE

-%E5%8F%8D%E7%99%BD2.png?width=200&height=52&name=SHINING%203D%20METROLOGY%20(RGB)-%E5%8F%8D%E7%99%BD2.png)

SHINING 3D Metrology brings precision measurement from isolated labs directly to the shop floor and beyond, enabling real-time quality assurance across every stage of production.

What You Can Achieve with Our Scanners

Discover how integrating our scanners into your workflow can enhance efficiency and help you achieve remarkable results.

-

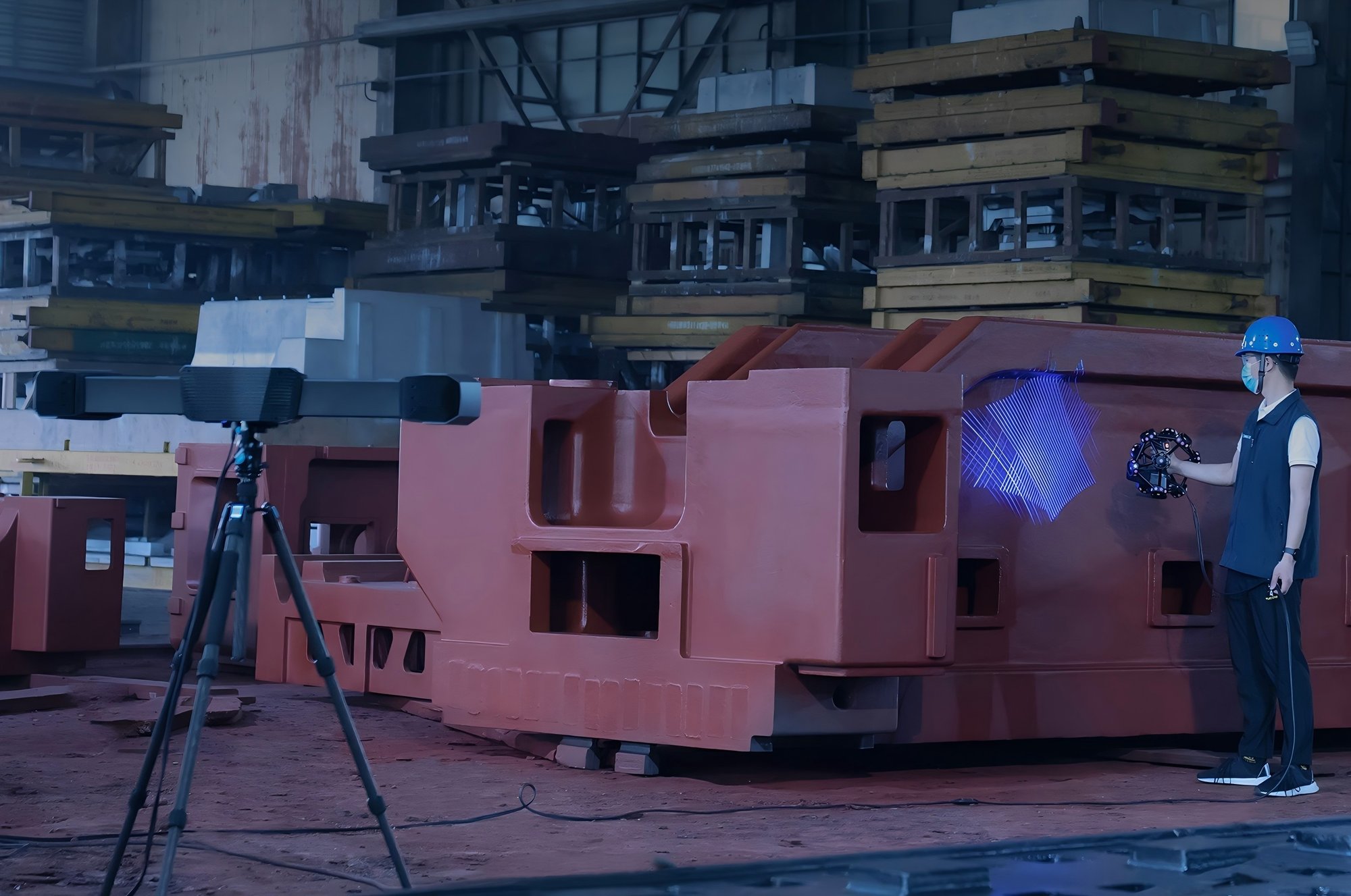

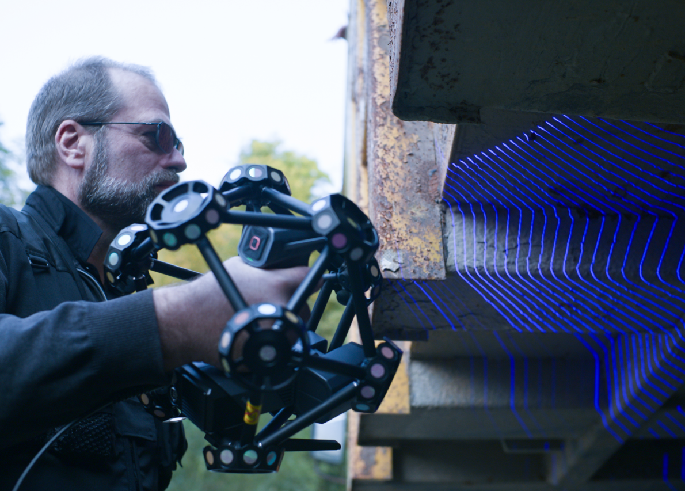

Engineering Machinery & Other Transportation

Equipped with three selectable laser line modes and a high-speed scanning feature, FreeScan Trak ProW ensures efficient and accurate data capture whether indoors or outdoors. This makes it an excellent choice for detailed scans of hull accessories and rail tracks, as well as for inspections and reverse engineering projects.

-

Energy & Heavy Industry & Public Utilities

The scanner's dynamic tracking capability enables precise scanning without the need for markers. This long-range tracking system supports a maximum tracking distance of up to 8.6 m, covering a single station area of up to 206.7 m³. Such extensive coverage makes it perfect for capturing large-scale, accurate data—ideal for applications like inspecting water turbines and petroleum drill bits for deformation and damage detection.

-

Automotive

FreeScan Trak ProW, with its three laser line modes, is capable of efficiently scanning both flat surfaces and intricate details. Coupled with powerful software, it makes an excellent tool for analyzing surface deformations and precisely measuring holes in sheet metal and other components.

FreeScan Trak Software

Real-Time Data Quality Visualization

Users can access the quality of scanned markers during video photogrammetry and check data completeness during scanning.

Intelligent Resolution

Automatically adjusts mesh resolution based on the object's curvature, ensuring clearer and more detailed features.

AI Feature Recognition

Inspection Module

Integrated an inspection module, certified by PTB, for reliable, high-quality full-size inspection.

Technical Data

- Accuracy 0.023 mm

- Resolution 0.01 ~ 10 mm

- Volumetric accuracy (based on measuring range) 15.6 m³: 0.046 mm; 45 m³: 0.063 mm; 76 m³: 0.088 mm; 128 m³: 0.127 mm

- Volumetric accuracy with VPG 0.044 + 0.012 mm/m (extension volume)

- Scan Speed 5,500,000 points/s

- High-speed scan Included (50 laser lines)

- Detailed scan Included (7 parallel laser lines)

- Deep pockets scan Included (1 laser line)

- Weight FreeTrak W: 8.2 kg; TE25W: 1.47 kg

- Connection Wireless & Wired mode (fiber optic)

-

Certifications

CE, FCC, ROHS, WEEE, KC, FDA, UKCA, IP50,

TELEC, TiSAX - Acceptance test VDI/VDE 2634 Part 3 & ISO 10360 Certified (Tested in the ISO/IEC 17025 Accredited Accuracy Lab)

Our Expertise, Your Advantage

years experience

authorized patents

3D scanners sold worldwide

-

SHINING 3D's 3D scanning technology allows us to work with acurracy and efficiency, ensuring we get as close to perfection as possible...This isn't just about technology. It's about precision, skill, and preserving history. With the right tools and the right partners, We can get to the next level while staying true to our legacy.

JAN EGUI COSTA,

Julia Automobile

Frequently Asked Questions

-

Is the scanner certified or traceable to standards?

Yes. The scanner provides inspection reports and calibration certificates traceable to international standards such as VDI/VDE 2634 and ISO 10360 (subject to the actual certificates issued). All calibration and verification procedures are performed in SHINING 3D’s accredited Accuracy Lab, which operates in accordance with ISO/IEC 17025 requirements

-

Does wireless connectivity affect accuracy?

No. Wireless connectivity handles only data transmission and does not affect the accuracy. -

How does 3D scanning improve quality control compared to manual measurement and CMMs?

3D scanning captures the full 3D geometry of a part in one measurement. Compared to manual tools, it enables 100% surface inspection, reduces operator errors, and detects shape deformations often missed in key-point checks. Compared to CMMs, it is faster and provides richer data, especially for complex or freeform surfaces.

-

What is volumetric accuracy?

Volumetric accuracy refers to the measurement precision of a scanner across its entire scanning volume, rather than the accuracy of individual points. It is a critical metric for inspecting large components, as it reflects how errors accumulate with distance. -

Does FreeScan Trak ProW require markers when scanning?

No. FreeScan Trak ProW uses advanced tracking technology that can scan without markers for most parts, although markers may be recommended for very large surfaces to ensure optimal accuracy. -

How is 3D scanning used for reverse engineering and 3D inspection?

3D scanning is used for reverse engineering by capturing the exact geometry of a physical object and converting it into a digital 3D model or CAD file when original design data is unavailable. For 3D inspection, scanned data is compared with the CAD model to quickly identify dimensional deviations, ensuring parts meet design and quality requirements. -

Is there a difference in scanning speed between wired and wireless modes?

Both wired and wireless modes have equivalent data transmission bandwidth under full operating conditions, ensuring consistent scanning speed in both modes.