PR/News

Published on 19th Sept. 2025

SHINING 3D Accuracy Lab Expands CNAS Accreditation, Elevating Calibration and Test Capabilities

Learn how SHINING 3D's expanded CNAS accreditation guarantees world-class precision and quality for its high-performance 3D scanning solutions.

SHINING 3D, a company specializing in 3D digitizing solutions, is pleased to announce that its Accuracy Laboratory has successfully passed the scope extension review from the China National Accreditation Service for Conformity Assessment (CNAS).

This achievement not only reaffirms the laboratory's advanced technical proficiency and robust quality management system but also marks a significant milestone in its capabilities. The expanded accreditation encompasses a broader range of services with more stringent technical requirements, thereby enhancing the company’s ability to ensure the precision of its 3D scanning equipment and providing a robust technical foundation for all product R&D and quality control processes.

.jpg?width=314&height=413&name=001(1).jpg)

The China National Accreditation Service for Conformity Assessment (CNAS) is the national accreditation body of China. Crucially, CNAS is a signatory to the International Laboratory Accreditation Cooperation (ILAC) and the Asia Pacific Accreditation Cooperation (APAC) Mutual Recognition Arrangements. This ensures that calibration and test reports issued by CNAS-accredited laboratories are recognized in over 100 countries and regions worldwide, giving them international authority.

A Commitment to International Standards and Product Quality

SHINING 3D Accuracy Lab first achieved CNAS accreditation (Accreditation No.: L18674) in July 2023, formally recognizing its capability to conduct dimensional accuracy calibration and test services independently. The lab has since established a strong reputation in measurement volume, traceability, and environmental control.

This latest accreditation expands the lab's recognized capabilities to include 3 calibration projects and 7 test projects, with 7 new items added. This enhancement injects powerful technical momentum into the entire quality control chain, from R&D to the production and manufacturing of SHINING 3D's high-precision 3D scanning products.

Slide to view more

The lab performs its services in accordance with a comprehensive range of internationally recognized standards, including:

-

VDI/VDE 2634 Part 1:2002: Optical 3D-Measuring Systems: Imaging systems with point-by-point probing

-

VDI/VDE 2634 Part 2:2012: Optical 3D-Measuring Systems: Optical systems based on area scanning

-

VDI/VDE 2634 Part 3:2008: Optical 3D-Measuring Systems: Multiple view systems based on area scanning

-

ISO 10360-12:2016: Geometrical product specifications (GPS) — Acceptance and reverification tests for coordinate measuring systems (CMS) — Part 12: Articulated arm coordinate measurement machines (CMMs)

-

ISO 10360-13:2021: Geometrical product specifications (GPS) — Acceptance and reverification tests for coordinate measuring systems (CMS) — Part 13: Optical 3D CMMs

-

ISO 20896-1:2019: Dentistry — Digital impression devices — Part 1: Methods for assessing accuracy

In addition to these international benchmarks, the lab also adheres to a range of national standards for specialized calibration and testing procedures.

- JJF 1951-2021: Calibration Specification for Optical 3D Measurement Systems Based on Structured-Light Scanning

- JJF 1859-2020: Calibration Specification for Standard Ball Bars

-

GB/T 16857.2-2017 / ISO 10360-2:2009: Geometrical Product Specifications (GPS) — Acceptance and reverification tests for coordinate measuring machines (CMMs) — Part 2: CMMs used for measuring linear dimensions

-

GB/T 34890-2017: Geometrical Product Specifications (GPS) — Acceptance and reverification tests for digital photogrammetry coordinate measuring systems

- GB/T 16857.8-2022 / ISO 10360-8:2013: Geometrical product specifications (GPS) — Acceptance and reverification tests for coordinate measuring systems (CMS) — Part 8: CMMs with optical distance sensors

With this expanded accreditation, the SHINING 3D Accuracy Lab can issue test reports bearing the CNAS mark, providing partners and customers worldwide with authoritative technical support and quality assurance.

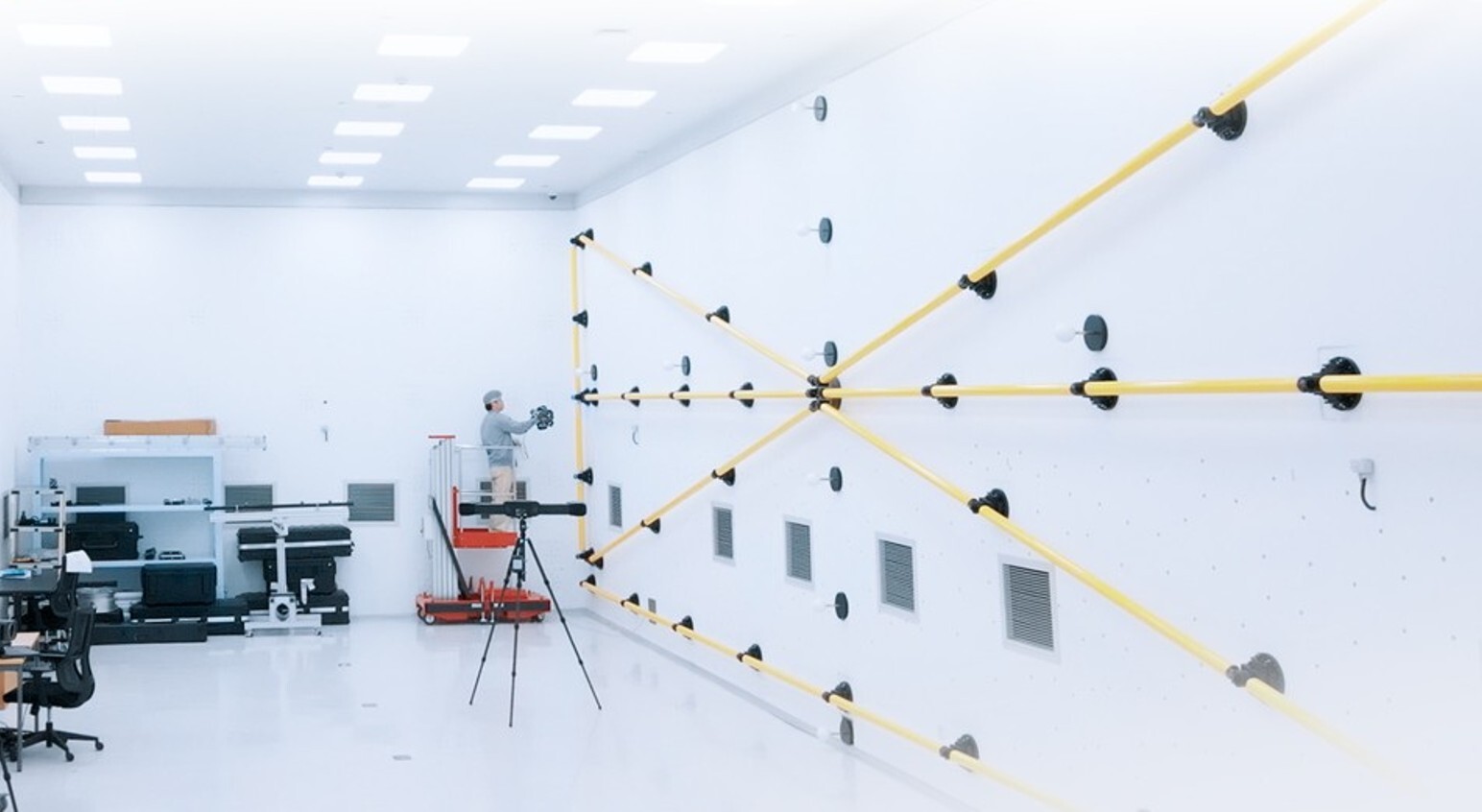

Inside the SHINING 3D Accuracy Lab's Capabilities

The state-of-the-art, 1100㎡ Accuracy Lab is the hub of SHINING 3D's precision assurance system. It plays a critical role in the entire product lifecycle—from algorithm research and hardware design to final product calibration—ensuring the metrology-grade accuracy of the company's 3D scanners and digital dental impression devices.

1. Professional Team

The lab is staffed by a highly skilled technical team led by senior engineers and includes certified metrologists and engineers. This team's deep theoretical knowledge and extensive practical experience ensure that all calibration and test tasks are performed with the utmost efficiency and accuracy.

2. Advanced Facilities & Traceability

To guarantee objective and scientific calibration, the lab operates under strict CNAS guidelines.

High-Standard Environment

The lab maintains constant temperature and humidity (20 ± 0.5°C, 40% ~ 60% RH) and employs rigorous vibration isolation measures. This minimizes environmental influences that could cause minute deviations in measurement results, ensuring data reliability.

Metrological Traceability

All measurement standards used in the lab are calibrated and traceable to national benchmarks through authoritative metrology institutes. Furthermore, high-precision equipment like CMMs, 2D vision measuring machines, and laser interferometers is used for regular internal verification, guaranteeing the long-term stability and reliability of the standards.

3. Integrated Quality Control for Mass Production

To ensure every 3D scanner produced meets high standards of accuracy and stability, the company integrates the lab's capabilities directly into its production workflow.

Laser Interferometer

CMM

CMM

High-precision metrology equipment is used to verify standards on the production line, and every metrology-grade scanner undergoes rigorous final accuracy verification according to VDI/VDE 2634 and ISO 10360 standards before being shipped with a full calibration and test report.

Driving the Future of Precision Measurement

With 20 years of expertise in high-precision 3D vision technology, SHINING 3D continues to push the boundaries of innovation. The company consistently reinvests approximately 20% of its annual revenue into R&D and has established a comprehensive research framework that includes R&D centers, a national post-doctoral workstation, and specialized facilities, including its Accuracy Lab and optics lab. This commitment has resulted in over 400 authorized patents (including 281 invention patents) and breakthroughs in measurement accuracy, achieving results as fine as 4 micrometers.

SHINING 3D also actively collaborates with national and provincial metrology institutions and has led or participated in the development of 7 national and industry standards for 3D vision.

The successful expansion of its CNAS accreditation is a significant milestone for SHINING 3D. It underscores the company's unwavering commitment to excellence and quality. Moving forward, SHINING 3D will continue to enhance its laboratory capabilities, further develop high-standard test projects, and leverage its technical expertise to provide trusted, high-precision 3D digital solutions for industrial and dental users worldwide.

For more info

💎 Read more about the calibration and certification system

Accuracy Certification Pathway: From CNAS Accreditation to VDI/VDE 2634 Calibration Certificate

💎 Read more bout the SHINING 3D calibration workflow

Ensuring Accuracy in 3D Scanning: Calibration Techniques and Accuracy Standards at SHINING 3D