Optical 3D Measuring and Dynamic Tracking System

The FreeScan Trak series is SHINING 3D’s high-end optical 3D tracking system developed for industrial-grade metrology applications. It is specifically designed to meet the high-accuracy 3D digitization needs of medium to large-sized workpieces in complex environments, offering exceptional 3D measurement accuracy, outstanding flexibility, and broad industrial adaptability.

No Markers Needed

FreeScan Trak series enables accurate 3D scanning without the need for manual placement of markers.

Certified Metrology Accuracy

Verified against VDI/VDE 2634 & ISO 10360 in our ISO 17025-accredited lab, the FreeScan Trak series delivers traceable, consistent precision.

Integrated Video Photogrammetry (VPG)

FreeScan Trak series features built-in photogrammetry, enhancing accuracy and stability for large-scale measurements.

Fast Scanning Speed

Dynamic Referencing, No Markers Needed

The FreeScan Trak series is equipped with advanced dynamic tracking technology, in which a tracker recognizes and captures the spatial position of the scanner and the scanned object in real time. It enables high-accuracy, markerless 3D scanning—making it particularly well-suited for large-scale industrial quality control applications.

.jpg?width=870&height=624&name=Trak%20Integrated%20Video%20Photogrammetry%20(VPG).jpg)

Integrated Video Photogrammetry (VPG)

FreeScan Trak series features Integrated Video Photogrammetry (VPG), enabling users to perform large-scale, high-accuracy measurements. By combining real-time video capture with advanced photogrammetry algorithms, the system automatically calculates spatial relationships between reference points, significantly enhancing global accuracy across large volumes. With a volumetric accuracy of up to 0.044 mm + 0.012 mm/m, VPG ensures highly reliable results even on complex or oversized parts.

Accuracy Guaranteed

Wide Measuring Range

FreeScan Trak series features a wide tracking range, enabling efficient scanning of large-scale volumes and complex surfaces without the need for traditional leapfrog* or compromising measurement accuracy. This significantly enhances operational convenience and overall measurement efficiency.

*(1) Leapfrog: Refers to the technique of relocating the measuring device to extend its working volume.

FreeProbe 2

Designed for fast, shop-floor measurements and inspections, FreeProbe 2 captures precise geometric data without generating mesh. It is ideal for hidden areas that scanners cannot reach, ensuring data acquisition with pinpoint accuracy.

Accuracy in Every Angle

Ideal for 3D dynamic tracking and scanning systems, Markers Kit for Dynamic Tracking System supports stable and precise tracking with different leapfrog marker options for scanning large and complex objects.

FreeProbe (Optional)

- Ergonomic design for easy grip and use

- Sturdy structure for enhanced durability and measurement accuracy

- Multi-functional button for versatile functionality

- Seamless integration with mainstream industrial inspection software

Designed for quick measurements and inspections, the FreeProbe captures precise geometric data without generating mesh. It is ideal for hidden areas the scanner cannot reach, ensuring data acquisition with pinpoint accuracy.

INSPECT ON THE MOVE

-%E5%8F%8D%E7%99%BD2.png?width=200&height=52&name=SHINING%203D%20METROLOGY%20(RGB)-%E5%8F%8D%E7%99%BD2.png)

SHINING 3D Metrology brings precision measurement from isolated labs directly to the shop floor and beyond, enabling real-time quality assurance across every stage of production.

-

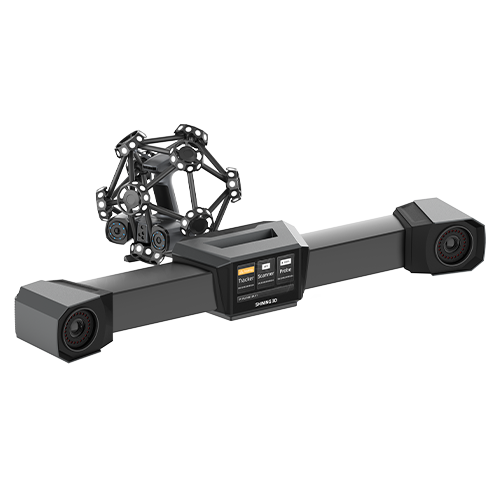

FreeScan Trak Nova

FreeScan Trak Nova integrates a portable tracking scanner, the largest-FOV handheld laser scanner, and video photogrammetry (VPG) module into one advanced wireless tracking system.

-

Scan Accuracy

0.02 mm -

Volumetric Accuracy

0.062 mm (12 m³) -

Scan Speed

6,140,000 points/s -

Point Distance

0.01 ~ 10 mm -

Maximum FOV

2600 x 2200 mm -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser -

Align Mode

Feature Alignment / Marker Alignment

-

-

FreeScan Trak ProW

FreeScan Trak ProW maintains core features such as marker-free scanning and guaranteed high accuracy of the FreeScan Trak Pro series, while introducing advanced upgrades for improved performance.

-

Scan Accuracy

0.023 mm -

Volumetric Accuracy

15.6 m³: 0.046 mm; 45 m³: 0.063 mm; 76 m³: 0.088 mm; 128 m³: 0.127 mm -

Scan Speed

5,500,000 points/s -

Point Distance

0.01 ~ 10 mm -

Maximum FOV

/ -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser -

Align Mode

Feature Alignment / Marker Alignment

-

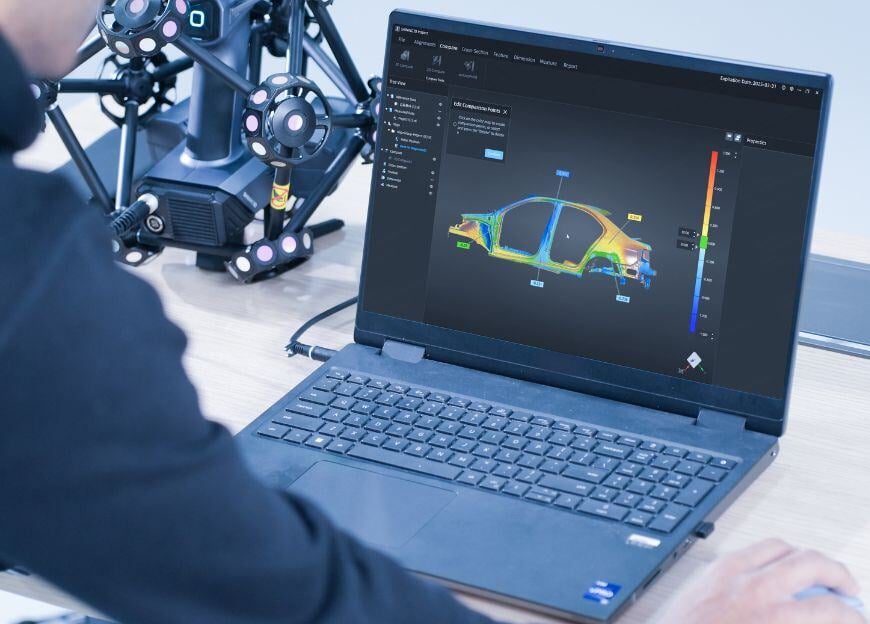

What You Can Do With These Tracking Systems

Discover the ways in which integrating our scanners into your workflow can enhance efficiency and help you achieve remarkable results.

-

Automotive

In the automotive industry, FreeScan Trak series scanners provide precise 3D digitization of components, assemblies, and prototypes. The scanners are ideal for inspecting complex shapes, detecting dimensional deviations, and accelerating the prototyping process, thus enhancing production speed and product quality control in automotive manufacturing.

-

Energy & Heavy Industry & Public Utilities

For energy, heavy industry, and public utilities sectors, the FreeScan Trak series offers robust and reliable scanning capabilities in challenging environments. These scanners are used to inspect large machinery, pipelines, power plants, and structural components. With their ability to capture high-precision data in industrial conditions, FreeScan Trak systems support asset management, maintenance planning, and ensure compliance with industry standards, all while improving the efficiency and safety of operations.

-

Engineering Machinery & Other Transportation

In engineering machinery and transportation, FreeScan Trak scanners provide highly accurate 3D measurements for large, intricate parts such as chassis, turbines, or transport vehicles. By improving alignment, detecting deformation, and optimizing design, these systems help ensure the reliability, safety, and performance of machinery and vehicles across various transportation industries, including civil aviation, rail, and maritime.

-

My experience with SHINING 3D has been very positive. Their products are reliable and continuously improving, which has been beneficial for our projects. The customer support is very impressive. They are very responsive and always ready to assist with any issues or questions. Overall, SHINING 3D's commitment to quality and customer satisfaction has made our collaboration very successful.

IVAN RADIČEVIĆ,

Quality Control Technician

-

We had the opportunity to test SHINING 3D’s newest Trak Pro2 system. It allows you to scan objects without the need for scanning markers, making it ideal for situations where you don't want to risk damaging expensive paint.

Misha Charoudin,

Race Director @ Vulcan Alpha

Trusted Worldwide

Let's explore why SHINING 3D's laser 3D scanner is the go-to choice for experts across various industries.

Frequently Asked Questions

-

What's the difference between Trak ProW and Trak Nova?

Trak ProW and Trak Nova operate wirelessly. Trak Nova combines UE Nova (a handheld wide-range scanner) and TE Nova, offering greater versatility. Meanwhile, Trak ProW has a larger tracking range, making it better for scanning large objects without markers. That range advantage sets it apart, though Trak Nova’s handheld capability remains a distinct selling point. -

What applications are FreeScan Trak series suitable for?

Trak ProW and Trak Nova are suitable for high-demand 3D measurement applications across various industries, including automotive, rail transportation, energy, education and research, and cultural heritage preservation.

-

How is 3D scanning used for reverse engineering and 3D inspection?

3D scanning is used for reverse engineering by capturing the exact geometry of a physical object and converting it into a digital 3D model or CAD file when original design data is unavailable. For 3D inspection, scanned data is compared with the CAD model to quickly identify dimensional deviations, ensuring parts meet design and quality requirements.

-

Does FreeScan Trak series support photogrammetry? Is there an additional fee for this?

Yes. All systems (Trak ProW, and Trak Nova) come with built-in photogrammetry function at no additional cost. Usually we recommend using photogrammetry mode for objects larger than 1.5 meters to get better measurement results. -

How does 3D scanning improve quality control compared to manual measurement and CMMs?

3D scanning captures the full 3D geometry of a part in one measurement. Compared to manual tools, it enables 100% surface inspection, reduces operator errors, and detects shape deformations often missed in key-point checks. Compared to CMMs, it is faster and provides richer data, especially for complex or freeform surfaces. -

Does FreeScan Trak series require markers when scanning?

No. FreeScan Trak series uses advanced tracking technology that can scan without markers for most parts, although markers may be recommended for very large surfaces to ensure optimal accuracy.