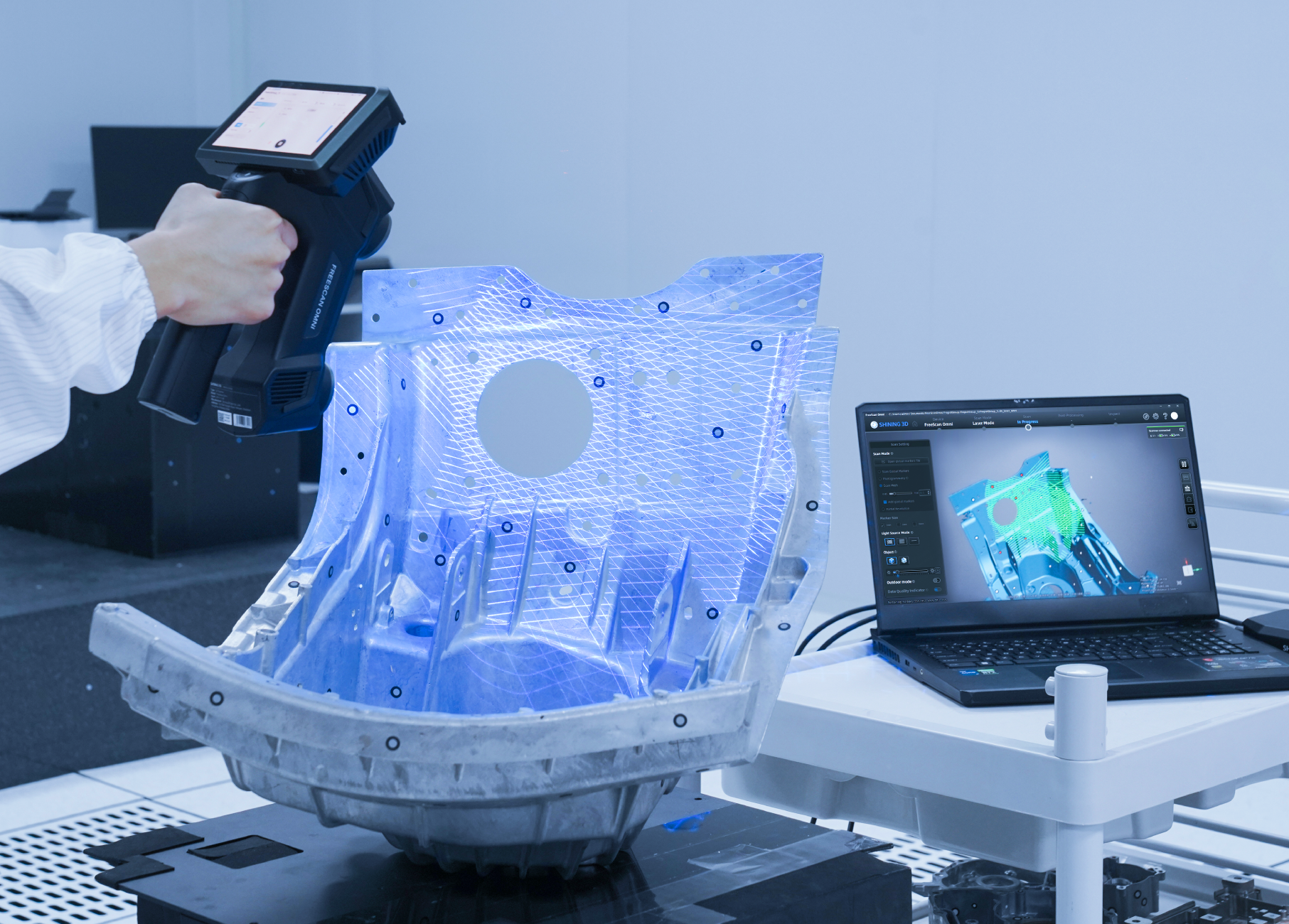

FreeScan Omni Series is the industry’s first wireless, standalone, certified metrology 3D scanning platform. Built with onboard computing and a scalable architecture, it enables high-performance, on-device scanning and inspection, while supporting flexible expansion for future applications.

FreeScan Omni Series

World's First Standalone Inspection-Ready Metrology 3D Scanner

- On-Scanner Scan-To-Inspect

- Certified Accuracy of 0.02 mm

- Multi-Mode & High-Performance

- Scalable Platform with Modular Expansion

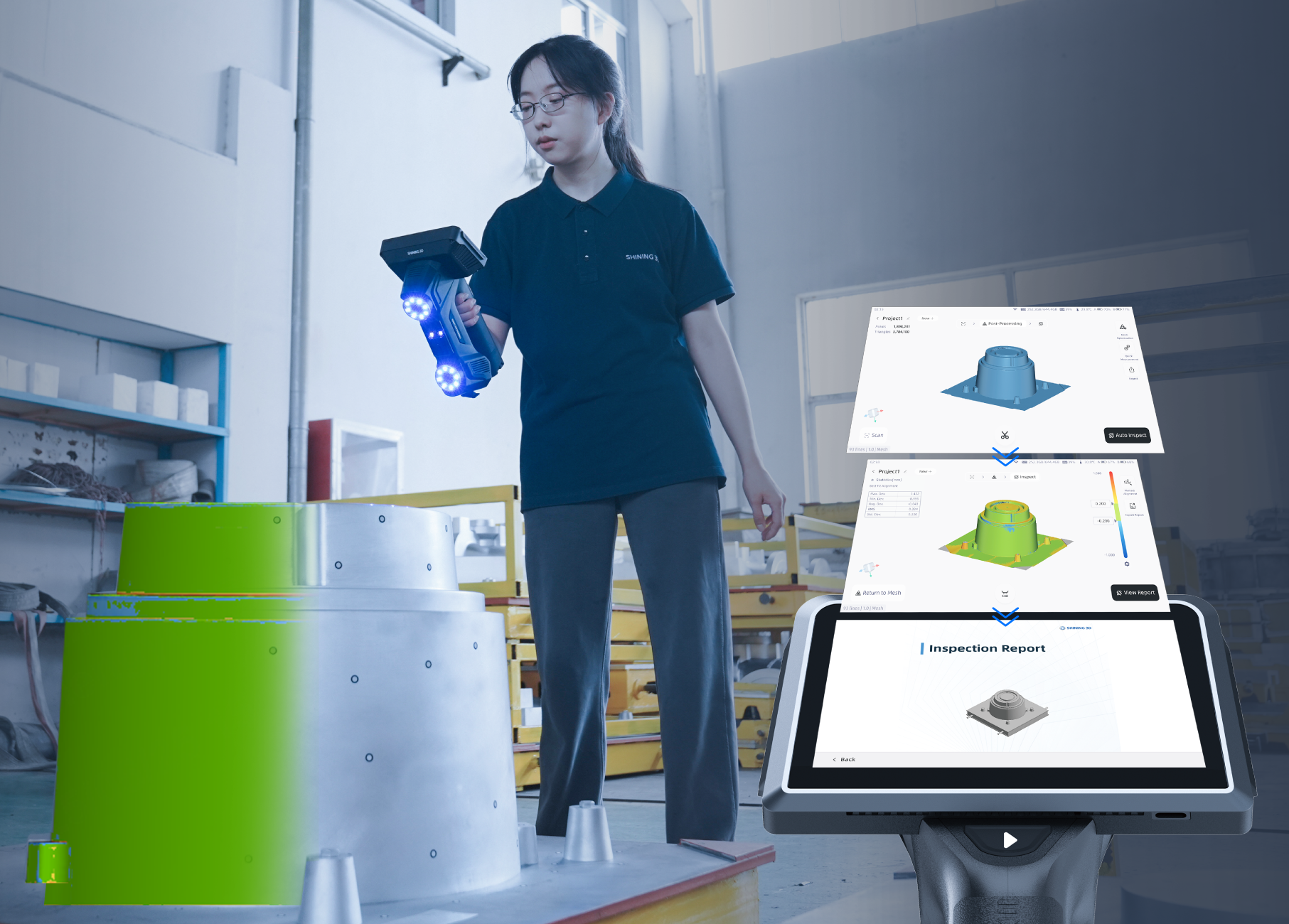

Metrology-Grade On-Scanner Inspection

- Built-in PTB-certified software

- Automated & intuitive inspection

- Effortless reporting & export

.png?width=1813&height=1300&name=Omni%E7%BD%91%E9%A1%B5%E5%9B%BE%E5%8C%85_Video%20Photogrammetry%20(VPG).png)

Video Photogrammetry (VPG)

FreeScan Omni Series supports SHINING 3D’s patented video photogrammetry (VPG), which eliminates the need for coded markers. By integrating photogrammetry technology with a calibration rod, it enables real-time marker verification through video capture. This ensures consistent volumetric accuracy and streamlines the setup process for efficient large-object scanning.

AI Feature Recognition

Intelligent boundary detection provides fast, precise measurement of round holes, rectangular holes, and slots, ensuring high-quality and high-accuracy data capture.

Flexible Expansion for Evolving Needs

FreeScan Omni is a fully integrated, on-device scan-to-inspect solution that completes scanning, inspection, and reporting in one flagship configuration.

FreeScan Omni Lite shares the same hardware foundation as FreeScan Omni, delivering certified accuracy, and high-performance scanning. As application needs evolve, FreeScan Omni Lite can be expanded with dedicated modules.

Engineered for On-Site Quality Control

- Certified metrology accuracy: Delivers reliable volumetric accuracy of 0.02 + 0.03 mm/m for reliable and consistent measurement results.

- Blazing-fast computing processor: Powered by a high-performance processor, FreeScan Omni Series leverages an edge-based computing module for rapid 3D scanning and data processing, significantly enhancing workflow efficiency.

Power without Limits

FreeScan Omni Series delivers a fully wireless experience, eliminating power cords and data cables. Scanning, processing, and inspection run entirely on the device. Detachable battery packs enable seamless swaps without downtime.

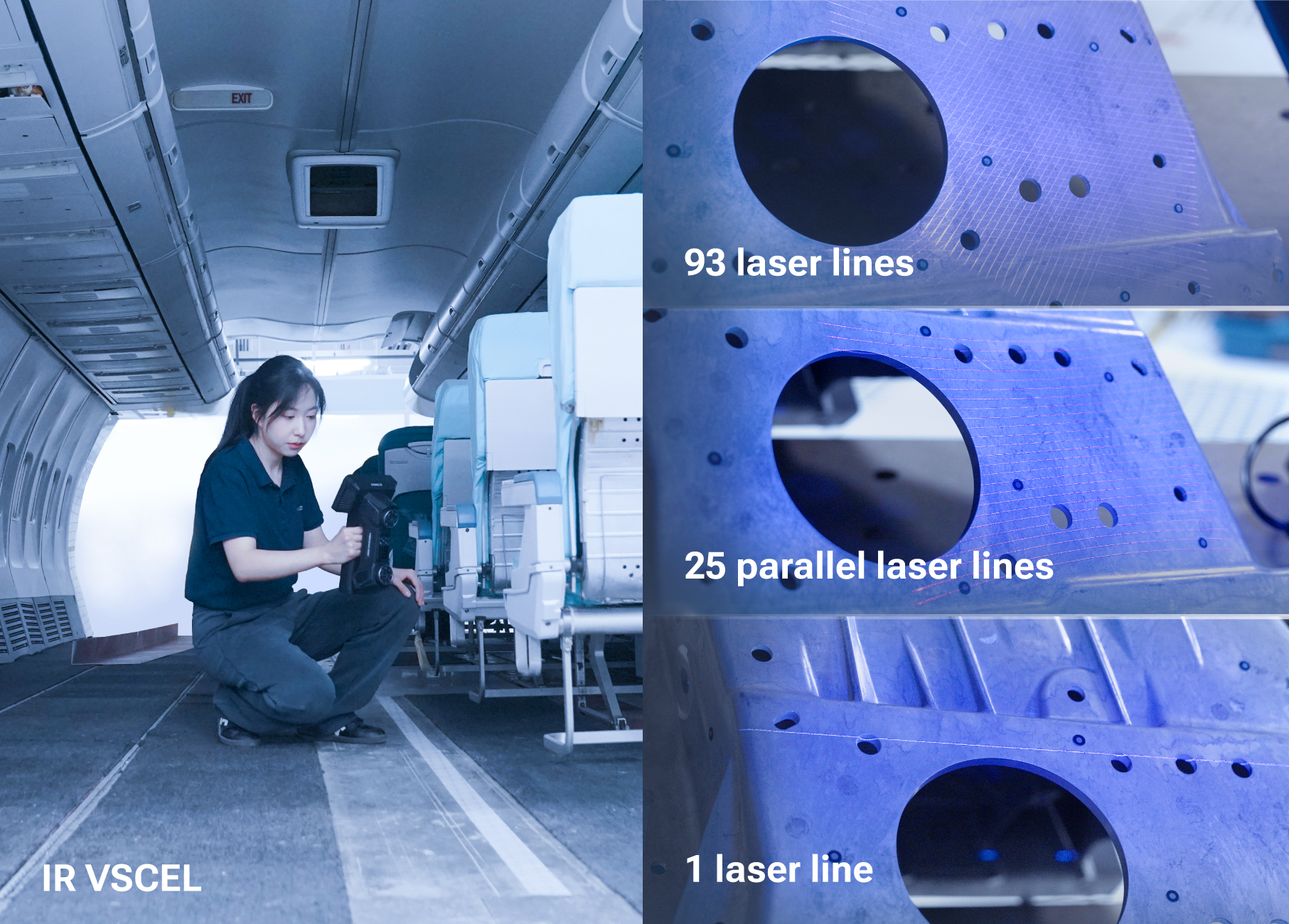

Multiple Scanning Modes for Industrial Usage

- High-speed scan mode with 93 laser lines for overall scans

- Detailed scan mode with 25 parallel laser lines

- Deep pockets scan mode with 1 laser line

- IR rapid scan mode for quick scans without markers

Power & Wi-Fi Set in One Dock

- Quick power boost — always ready to go.

- Auto network setup — just dock once to connect.

Our Support Coverage

INSPECT ON THE MOVE

-%E5%8F%8D%E7%99%BD2.png?width=200&height=52&name=SHINING%203D%20METROLOGY%20(RGB)-%E5%8F%8D%E7%99%BD2.png)

SHINING 3D Metrology brings precision measurement from isolated labs directly to the shop floor and beyond, enabling real-time quality assurance across every stage of production.

What You Can Achieve with Our Scanners

Discover how integrating our scanners into your workflow can enhance efficiency and help you achieve remarkable results.

-

Automotive

FreeScan Omni Series is engineered for outstanding adaptability, effortlessly handling a wide range of surface types, including highly reflective and black surfaces. Its advanced Infrared (IR) mode further enhances flexibility by enabling marker-free scanning, making it a highly versatile solution.

-

Construction Machinery

Designed for demanding environments, FreeScan Omni Series excels in construction machinery applications, delivering high-accuracy, standalone scanning for complex structural components, enhancing efficiency and precision directly on the job site.

-

Energy / Heavy Industry

Untethered from cables and laptops, this versatile scanner allows effortless mobility between workspaces. Equipped with a 5.5-inch touchscreen and rechargeable batteries, it delivers a streamlined and user-friendly onsite scanning experience.

-

General Manufacturing Equipment

In the general manufacturing equipment industry, FreeScan Omni Series enables high-precision, standalone scanning of complex machinery parts, streamlining quality control and accelerating reverse engineering workflows, all without the need for external cables or laptops.

|

Highlights |

FreeScan Omni | FreeScan Omni Lite |

|---|---|---|

| SHINING3D Inspect module for PC |

✅ |

⭕ |

| On-device inspection |

✅ |

⭕ |

| Video Photogrammetry (VPG) |

✅ |

⭕ |

| AI Feature Recognition |

✅ |

⭕ |

| Two Work Modes(PC and Standalone mode) |

✅ |

✅ |

|

Multiple Scanning Modes (high speed / detailed / deep pockets / IR scan) |

✅ |

✅ |

Technical Data

- High-speed scan Included (93 laser lines) | VCSEL

- Detailed scan Included (25 parallel laser lines)

- Deep pockets scan Included (1 laser line)

- VPG Supported (no coded markers required)

- Accuracy 0.02 mm

- Volumetric accuracy 0.02 + 0.03 mm/m

- Volumetric extension accuracy with VPG 0.02 + 0.015 mm/m

- Scan speed 7,619,000 points/s

- Resolution 0.01 ~ 10 mm

- Max. FOV Laser: 580 x 650 mm; IR: 1205 x 1104 mm

- Connection Wireless & Wired mode

- Depth of field 830 mm (170 ~ 1000 mm)

- Net weight ≤1.1 kg

- Certifications CE, FCC, ROHS, WEEE, KC, FDA, UKCA, IP50, TELEC, TiSAX

- Acceptance test VDl/VDE 2634 Part3, ISO 10360 (certified in ISO 17025 certificated accuracy lab)

Our Expertise, Your Advantage

years experience

authorized patents

3D scanners sold worldwide

-

_RGB-1.png?width=230&height=55&name=SHINING%203D%20LOGO%20(EN)_RGB-1.png)

FreeScan Omni is the first handheld scanner we’ve seen that can be fully operated without a PC while still delivering performance comparable to a workstation-connected device. For a company like ours, being agile is essential.

Antonio Weixler,

Project Engineer at KE-TEC GmbH

-

We tested FreeScan Omni today by going through the full workflow, from scanning a part, inspecting it, to generating a ready-to-share inspection report for managers and clients. Everything worked seamlessly. What really stood out is that the entire process is built into the scanner itself, all done in one place, right on the device.

Bradley Jack,

Zero3D

-

I'm truly impressed that a handheld device has the computational power to scan and deliver live results right on the spot. It’s incredibly convenient, not having to go back and forth to a computer for analysis is a game-changer. It just works. Simple and efficient.

Dr. Christian Höhl,

Sparkel GmbH

-

What I really appreciate about the FreeScan Omni is that it has a built-in inspection module, including reporting, right out of the box. It makes the whole process incredibly easy. With the color map, you can instantly see whether the part meets the specs. It's much faster and more streamlined than traditional workflows.

Timmy Schramm,

OKM 3D

Frequently Asked Questions

-

How long is the battery life of FreeScan Omni?

FreeScan Omni requires 4 batteries to operate. Each package includes 8 rechargeable batteries, allowing for continuous scanning of up to 1 hour per set. Thanks to its hot-swappable battery design, you can replace batteries without shutting down the device, enabling uninterrupted scanning.

-

Is the SHINING3D Inspect module permanently maintained and updated after purchasing the Omni?

Yes, SHINING 3D will continuously maintain and update the SHINING 3D Inspect software and bring new features and improvements, ensuring the software remains powerful and up to date. All FreeScan Omni customers will receive these updates.

-

Is the scanner certified or traceable to standards?

Yes. The scanner provides inspection reports and calibration certificates traceable to international standards such as VDI/VDE 2634 and ISO 10360 (subject to the actual certificates issued). All calibration and verification procedures are performed in SHINING 3D’s accredited Accuracy Lab, which operates in accordance with ISO/IEC 17025 requirements.

-

How is an industrial 3D scanner calibrated?

SHINING 3D scanners are calibrated using certified artifacts or calibration panels traceable to metrology standards. Regular calibration ensures measurement traceability, maintains accuracy, and aligns the scanner with quality management requirements.

-

How is high accuracy maintained when scanning large objects?

FreeScan Omni comes with a validated scale bar in the package that being integrated with SHINING 3D video photogrammetry technology to verify markers in real time, which is also reusable for multiple times to improve overall accuracy for large object scans.

-

Does the product support wireless connectivity?

Yes. The scanner features wireless transmission modules, reducing on-site wiring and enhancing flexibility for mobile measurement.

-

Does wireless connectivity affect accuracy?

No. Wireless connectivity handles only data transmission and does not affect the accuracy. -

What light sources are used by this 3D scanner for data acquisition?

FreeScan Omni supports blue laser and IR VCSEL for data acquisition.

Blue laser: Low sensitivity to ambient light and surface reflectivity. It is well suited for industrial inspection and high-accuracy applications.

IR VCSEL: Efficient for large objects, infrared light remains invisible during scanning, enabling comfortable facial or body scanning.