High-Accuracy 3D Scanning Solutions for Engineers for Makers for Designers for Educators for Dentists for Everyone

SHINING 3D develops high-accuracy 3D scanners for a wide range of applications. Our solutions are ideal for use in high-precision metrology, digital dentistry, and more.

0

years of experience

0

+

patents

0

K+

3D scanners sold worldwide

Our High-Accuracy 3D Scanning Solutions

Discover our 3D scanning solutions for metrology, engineering, and digital dentistry. We develop laser scanners, blue light scanners, handheld scanners, and more.

A Look at Our Latest 3D Scanners

Explore our latest 3D scanners, designed for precision, versatility, and efficiency. Combining innovative features and user-friendly designs, they deliver exceptional performance for a wide range of applications. Discover the future of 3D scanning today.

📣 Join Our Reseller Program

Partner with us to bring high-accuracy 3D vision solutions to the world!

Together, let’s make advanced 3D scanning technology accessible to industries everywhere.

Our Core Technology

We’ve been dedicated to optical 3D measurement, focusing on accuracy and innovation since 2004. Our products are known for their high accuracy, high precision, excellent texture quality, and fine geometric details.

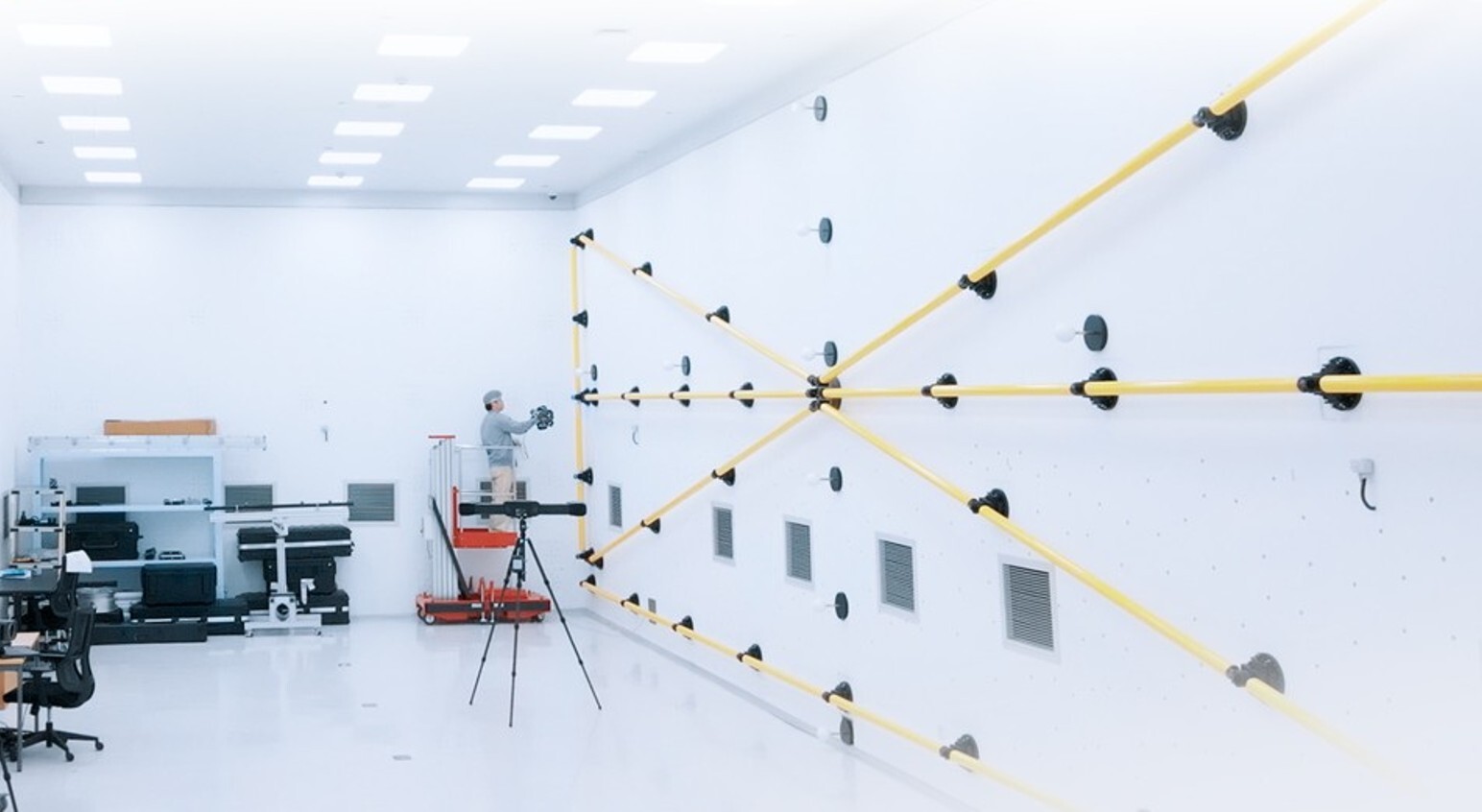

Verified Precision:

Inside Our 1100㎡ CNAS-Accredited Accuracy Lab

This expansive, CNAS-accredited facility is staffed by expert metrologists and certified to perform a comprehensive range of advanced calibration and testing projects. By rigorously adhering to the strictest international standards (like VDI/VDE and ISO), we ensure every 3D scanner, from R&D to production, is verified for world-class, metrology-grade accuracy.

INSPECT ON THE MOVE

-%E5%8F%8D%E7%99%BD2.png?width=200&height=52&name=SHINING%203D%20METROLOGY%20(RGB)-%E5%8F%8D%E7%99%BD2.png)

SHINING 3D Metrology brings precision measurement from isolated labs directly to the shop floor and beyond, enabling real-time quality assurance across every stage of production.

Trusted Worldwide

Let's explore why SHINING 3D is the go-to choice for experts across various industries.

-

.png?width=1614&height=907&name=redbull(1).png)

"I definitely see 3D scanning as an integral part of motorsports in the future. Because in motorsports, it's often custom solutions. And to solve it, 3D scanning can always help. I think 3D scanning will become a standard in motorsports".

Elias Hountondji,

Pilot & Engineer @RedBull DriftBrothers

-

.png?width=1610&height=905&name=babylon(1).png)

"I‘d really like to thank SHINING 3D for really pushing the limits of technology and giving their customers something that they can use in a practical basis, everyday basis to help my business grow as well".

Saad Kanno,

Babylon Engineering

-

"There are a lot of people with amputations in Africa, and most of them have never been to school or only have some basic knowledge. the EinScan H2 has made it possible for those without too much knowledge to learn and use it well. It is worth mentioning its accuracy, which helped us a lot".

Merel van der Stelt,

PhD, 3D Lab Radboudumc

-

"SHINING 3D is a good partner. They are always open to face challenges and keeps learning. When we provide the needs, they always understands our needs and then creates the products we want ".

Michel Babin,

CEO, TechMed

-

"I work with a lot of companies, but I have to say that SHINING3D has the best customer service. They are committed to promoting the user experience, and when I have a problem, it is always resolved with incredible speed".

Terence Whitty,

Owner, Fabdent

-

"SHINING 3D has many awesome products, such as Aoralscan 3. It's a great product, compared to others, it's lighter, scans faster, more accurate, and very easy to operate. It has helped make the experience more efficient and comfortable for my clinic and my patients".

Dr. Mark A. Kleive,

Owner, Mark Kleive DDS PA

-

"SHINING 3D has a complete line of dental products which are used in my entire workflow. It has dramatically reduced my chair time with patients and increased my work efficiency ".

Dr. Isaac Tawil,

Co Director, Advanced Implant Education