CASE STUDIES

Published on Dec. 26th 2024

Thai Manufacturer Cuts Aircraft PMA Components Inspection Time to Half a Day with SHINING 3D Metrology Scanner

This case study explores how a Thai manufacturer evaluated 3D scanning technology to improve their inspection workflow and highlights the potential benefits demonstrated during their trial with SHINING 3D.

Company Overview

The Thailand-based manufacturer specializing in the design, certification, and production of key aircraft components—including Class 3 PMA parts for wheels, brakes, and helicopter systems—recently explored digital metrology solutions to enhance their operations. The company also provides aerospace chemicals, cleaning tools, and engine start-up systems tailored for aviation use. Their engineering team, comprising 12 professionals, is committed to meeting stringent safety and regulatory requirements across all product lines.

The Challenge: Manual and CMM Inspections

Prior to exploring 3D scanning, the company primarily relied on Coordinate Measuring Machines (CMM) for inspecting PMA components. While CMMs deliver high accuracy, they often require extensive setup—such as custom jigs and programming—which could take up to three days per part. Measuring curved or complex surfaces posed additional difficulties, and the need for skilled operators further slowed down the process.

These challenges prompted the team to search for alternative technologies that could potentially improve inspection efficiency while maintaining precision.

Inspection with a CMM, a time-consuming method

Inspection with a CMM, a time-consuming method

These factors led the company to seek an alternative that would improve efficiency and reduce turnaround time.

Exploring 3D Scanning Technology

Given the shape and complexity of their parts, 3D scanning emerged as a promising alternative. The company began evaluating several scanning solutions and conducted a trial of the FreeScan Combo+ from SHINING 3D. During testing, the scanner stood out for its speed, portability, and intuitive user experience.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

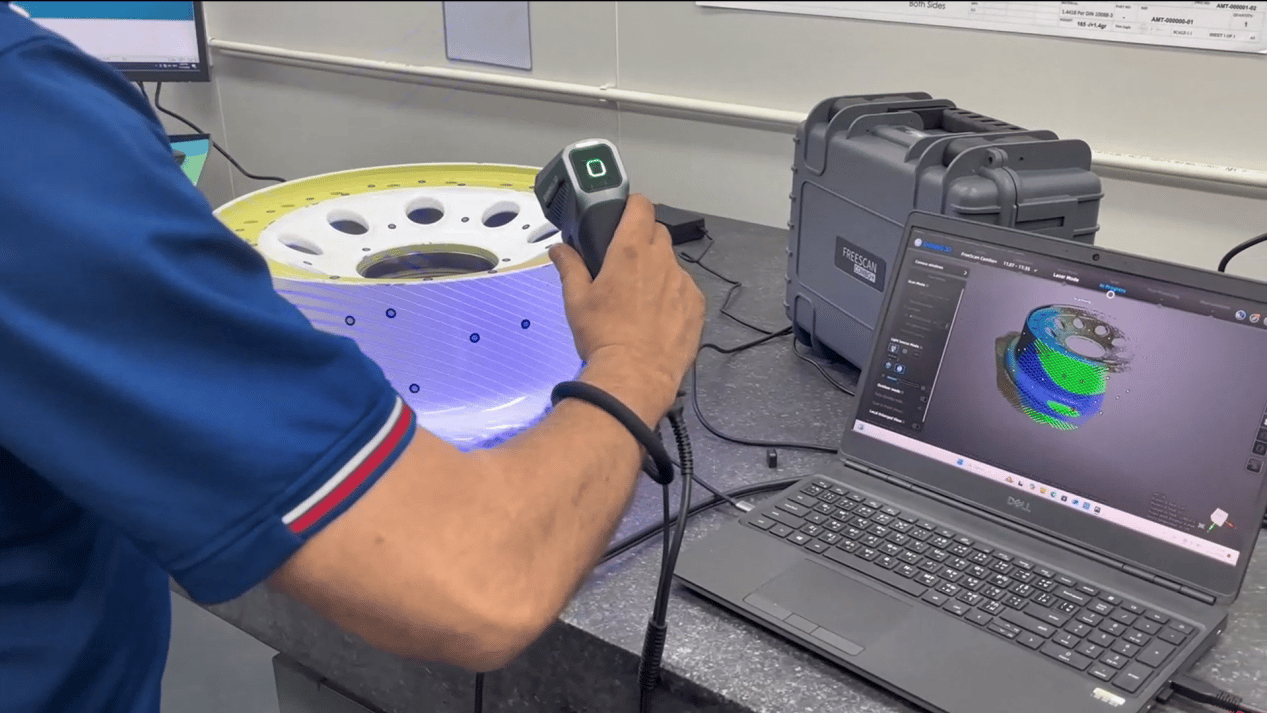

3D Scanning with FreeScan Combo+

By adopting the FreeScan Combo+, the company was able to address several key pain points:

- Reduced Setup Time: Unlike CMM, the FreeScan Combo+ does not require detailed programming before scanning. For the same part, a CMM would take 2-3 days to set up the program and start collecting data. With the FreeScan Combo+, all you need to do is connect the power supply to the computer,and the data can be captured in less than half a day.

- No Jig or Fixture Requirement: The 3D scanner’s ability to collect data without the need for part fixation or complex jigs streamlined the process. In some cases, parts inspection by CMM requires the use of multiple fixtures, which can take up to three days to design and manufacture. However, with the 3D scanner, you have the freedom to change the angle of the scanner for scanning or to flip the part over.

- Portable and Ease of Use: The FreeScan Combo+ is a real lightweight scanner that can be taken anywhere for scanning easily. That's what CMM can't handle. It was also recognized for its user-friendly interface. The company found it easy to operate, even for team members without specialized skills in 3D scanning. “You'll only need half a day at most to familiarize yourself with how to use it,” an employee said.

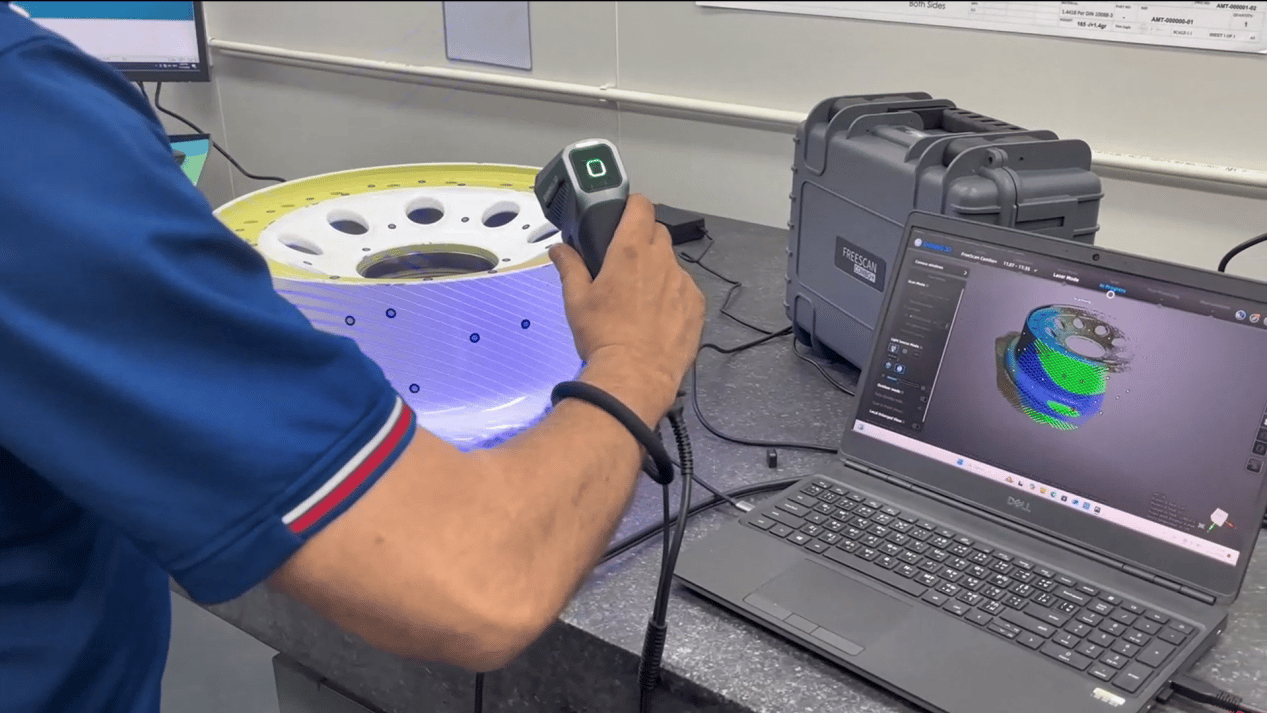

3D data acquired by FreeScan Combo+

3D data acquired by FreeScan Combo+

In addition to the scanner’s performance during the trial, the Thai company appreciated SHINING 3D’s thorough demonstration and knowledgeable support team. The ability of SHINING 3D staff to address technical questions, combined with their established presence in Thailand, helped build trust during the evaluation process.

The company is now considering broader applications for 3D scanning across its workflow, including prototyping, quality assurance, and design optimization.

Are you wondering in which workflow segment 3D scanning can help you? Please do not hesitate to contact us for a customized solution!

FreeScan Combo

The powerful FreeScan Combo packs dual light sources in an ultra-compact shell, measuring just 193x63x53mm. It's equipped with both blue laser and infrared VCSEL technology and weighs in at only 620g.

- Blue laser & Infrared light

- 4 Scanning modes to cover all types of workpieces

- Lightweight