CASE STUDIES

Published on Jan. 6th 2026

Inside Steelstruct: Using SHINING 3D Scanners to Speed Up Heavy Equipment Refurbishment

Steelstruct improved heavy equipment inspection and refurbishment by FreeScan Trak Nova, achieving metrology-grade accuracy, faster turnaround times, and data-driven quality decisions.

Overview

Steelstruct, a Western Australian steel manufacturing company, has significantly improved its engineering, inspection, and refurbishment workflows by adopting SHINING 3D’s FreeScan Trak Nova 3D scanning system. By integrating metrology-grade 3D scanning across its operations, Steelstruct has achieved higher accuracy, faster turnaround times, and greater confidence in quality-critical decisions.

SteelStruct: delivers tailored solutions to the mining, mineral processing, infrastructure and defence sectors all completely in house.

With more than 40 years of experience delivering process-critical equipment to the mining, mineral processing, infrastructure, and defense sectors, Steelstruct operates as a full-service supplier, from design and manufacturing through to installation and commissioning.

Challenges in Large-Scale Industrial Equipment Assessment

Steelstruct routinely handles components ranging from small precision parts to structures as long as an Olympic swimming pool. One recurring challenge is the condition assessment and refurbishment of large, heavy equipment returned from harsh operating environments.

A key example is a trommel screen shell, a 15-ton component used in mineral processing plants to separate crushed material. Traditional inspection and measurement methods were time-consuming, limited in coverage, and lacked the detailed accuracy required to compare real-world wear against CAD models.

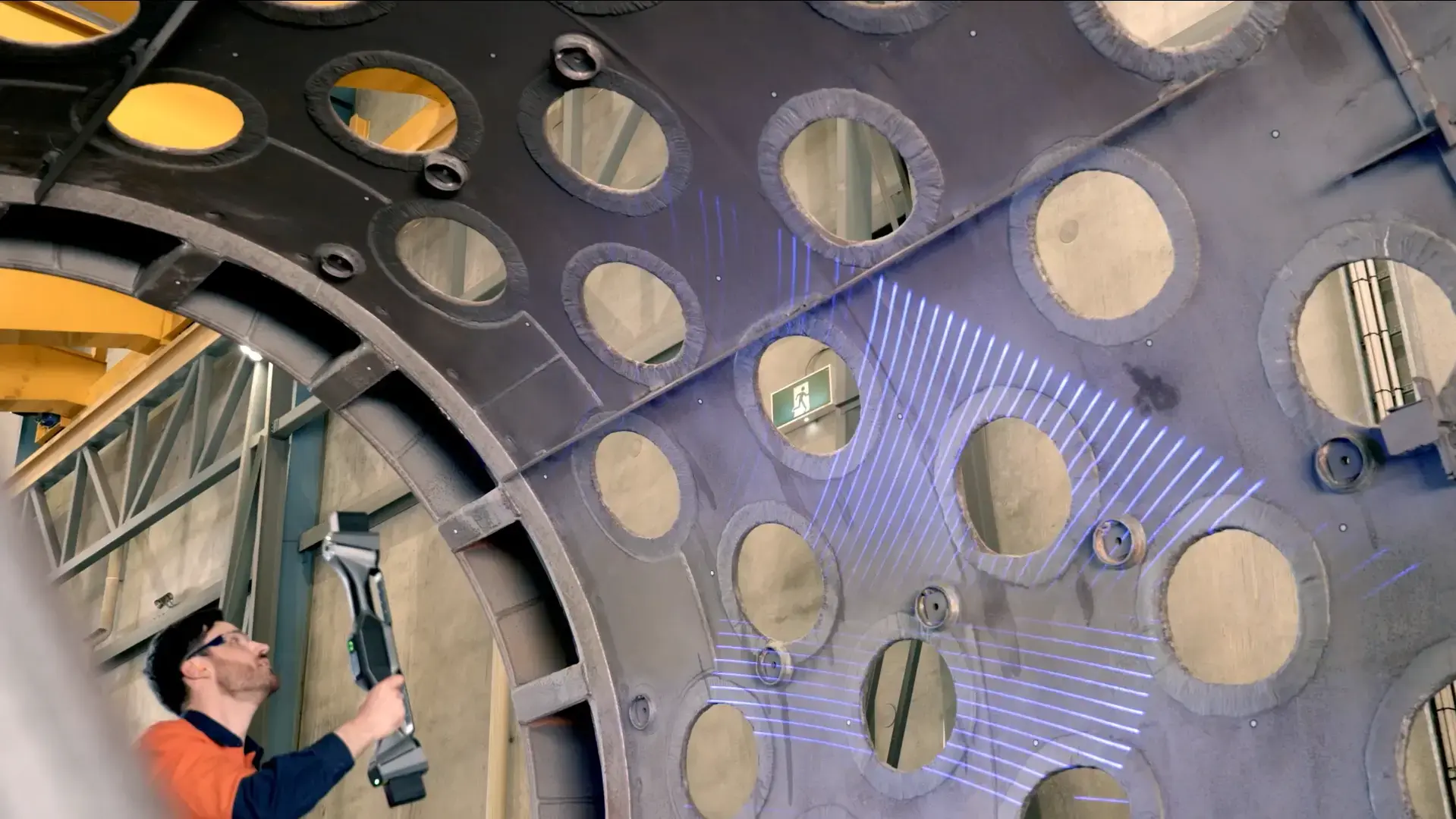

Trommel screen shell

Earlier generations of 3D scanning technology were available at Steelstruct but saw limited adoption due to equipment constraints and workflow inefficiencies.

Why Steelstruct Chose SHINING 3D FreeScan Trak Nova

With major advancements in 3D scanning technology over the past decade, Steelstruct made a strategic decision to deploy scanning solutions across the entire business. After evaluation, the company selected the SHINING 3D FreeScan Trak Nova for several key reasons:

- Certified metrology-grade accuracy for quality assessment and engineering

- Wireless and portable design, ideal for both workshop and on-site scanning

- Versatility, supporting applications from small components to very large structures

- High confidence in measurement data

For the trommel screen project, Steelstruct used a two-stage 3D scanning workflow:

FreeScan UE Nova

- High-speed, large-volume scanning

- Captured an accurate mesh of the entire trommel screen body

Capturing the entire trommel screen body by FreeScan UE Nova

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

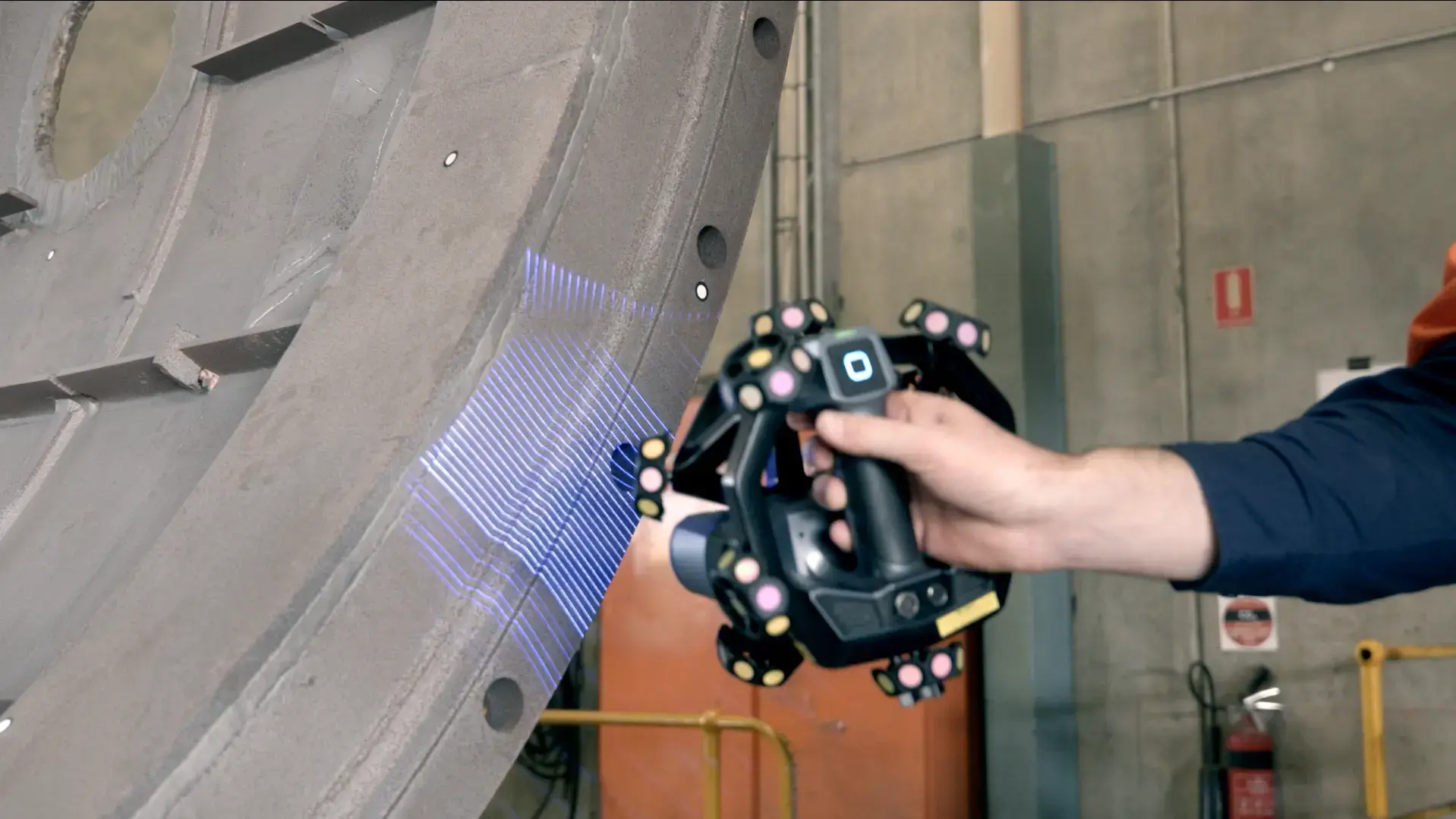

FreeScan Trak Nova

- High-detail, deep-hole scanning

- Precisely captured the flange bolt pattern and critical interfaces

The resulting scan data was compared directly against the original CAD model, allowing engineers to identify deviations outside manufacturing tolerances and determine exactly where rectification was required as part of the refurbishment process.

Data Inspection results

Data Inspection results

Results and Business Impact

The adoption of SHINING 3D scanning technology has delivered clear, measurable benefits for Steelstruct:

- Measurable Outcomes

- Dramatically reduced inspection time: tasks that previously took days now take only hours

- Improved decision-making through accurate, data-driven condition assessment

- Higher refurbishment quality, ensuring components meet strict tolerance requirements

As the primary user of the system, Steelstruct’s engineering team reports high satisfaction with both FreeScan Trak Nova and the end-to-end SHINING 3D workflow.

FreeScan Trak Nova

FreeScan Trak Nova is built to meet the diverse needs of industries requiring accurate and efficient large-scale measurements with extreme portability, productivity and versatility.

- Flexible & Separable System

- Compact & Agile Dynamic Tracking

- Wireless & Lightweight Design

- Integrated Video Photogrammetry (VPG)