0.02 mm

3D Scanning for Marine

The marine industry faces rising demands for efficiency, safety, and precision — from shipbuilding and hull inspections to retrofits and custom vessel outfitting. 3D scanning for marine applications delivers highly accurate data, accelerates design and production workflows, and ensures compliance with strict maritime standards.

Overview

3D Scanning in Marine Industry

Compared to conventional measurement tools, 3D scanning offers

High Versatility

Captures complex, large-scale marine components (hulls, propellers, superstructures) with diverse shapes and materials.

High Accuracy

Achieve tolerances down to 0.005–0.05 mm, enabling precise alignment, fitting, and repair.

High Efficiency

One comprehensive scan yields full surface and structural data, reducing manual measurements and rework.

Portability

Scanners can be used aboard docked vessels, in shipyards, or on offshore platforms — even in difficult environmental conditions.

Ease of Use

Intuitive software, quick setup, and feature-rich tools make scanning accessible to marine engineers and technicians.

Automation

Integration with robots or automated moving platforms for consistent and seamless inspection workflow.

Applications in Ship Design & Development

3D scanning technology reduces design and development cycles while improving data fidelity and working efficiency.

Initial Modeling

Scan reference hulls, physical models, or related components for initial design modeling and greatly improves modeling efficiency.

Spatial Layout Planning

Obtain realistic 3D environmental models for facility layout, piping routing, and other designs.

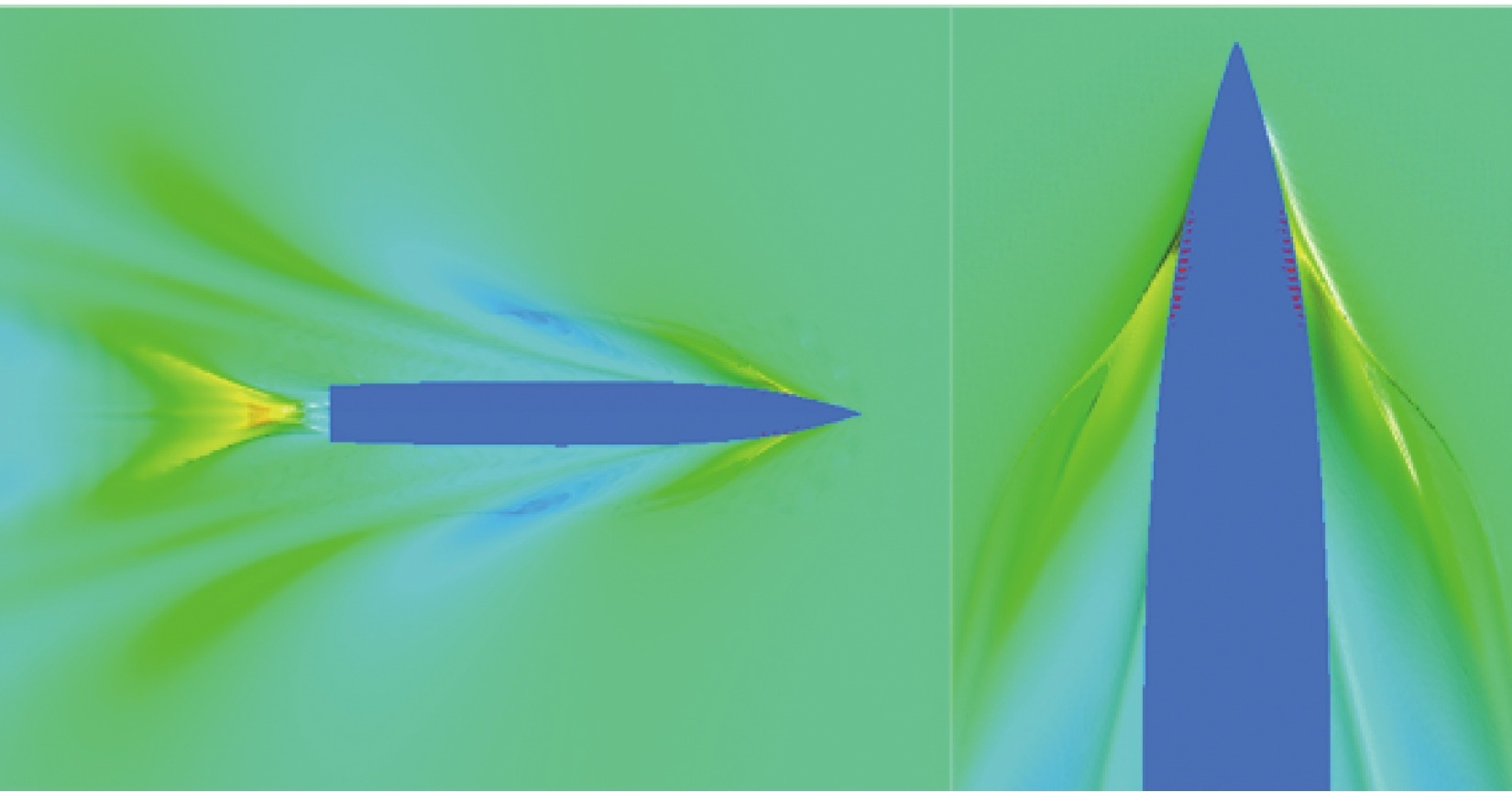

CFD

Importing the model into specialized software to analyze fluid flow, reducing the need for physical testing and accelerates the design process.

Applications in Ship Construction

3D scanning enhances ship manufacturing in steel structure construction and mold-based construction.

Mold Surface Inspection

Scan the mold surface to detect curvature deviations or surface waviness.

Post-Molding Quality Control

Steel Component Inspection

Scan cut steel plates and prefabricated parts to verify dimensional accuracy.

Block Fabrication Accuracy Check

Scan large hull blocks after welding or fitting. Compare actual geometry to digital design to identify distortion or misalignment.

Block Alignment & Fit-up

3D scanning of block interfaces enables comparison with the design model to detect misalignments and gaps.

Outfitting Installation Support

Before installing piping supports, foundations, or machinery, scan the onboard environment. Use virtual fitting to detect interferences and pre-adjust component positions.

Applications in Operation & Maintenance

3D scanning streamlines marine operation and maintenance by enabling accurate inspection, damage tracking, and data-driven repair decisions.

Digital Archives

3D scanning enables efficient, accurate digital twins of ships, enhancing lifecycle management with improved maintenance, inspections, and traceability.

VR Training

By integrating 3D scanning with VR, seafarers can train in realistic, repeatable, and accessible digital simulations that enhance safety, emergency response, and competency testing.

Corrosion & Repairing

3D models capture surface defects and, through comparison with historical scans, enable automated damage quantification, tracking, and data-driven maintenance decisions.

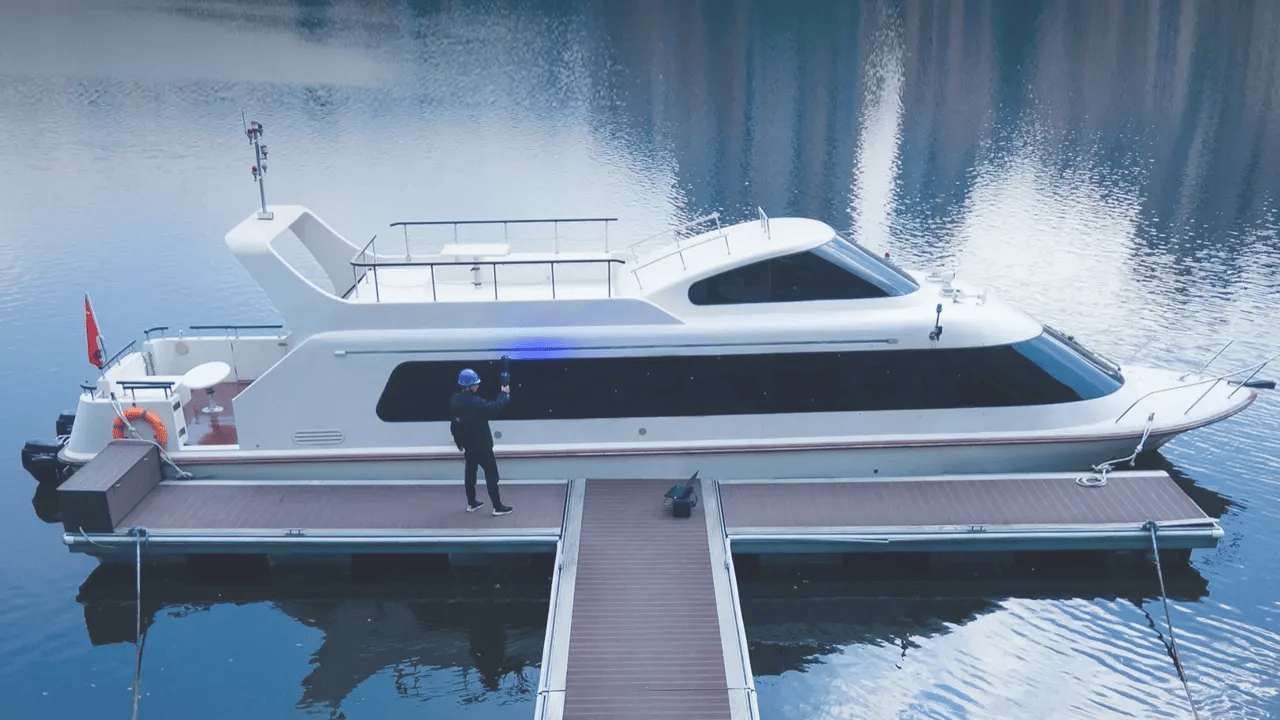

Applications in Customized Modification

3D scanning streamlines marine operation and maintenance by enabling accurate inspection, damage tracking, and data-driven repair decisions.

Yacht Modification

.webp?width=2000&height=1125&name=ship%20propeller%20(3).webp)

Life Extension

Functional Transformation

Converting a ship from its original purpose to a vessel with entirely new functions. Examples include converting an oil tanker into a floating production storage and offloading (FPSO) or converting a cargo ship into a scientific research vessel.

Discover Our 3D Metrology Solutions for Marine Industry

High-accuracy 3D scanning in

- Ship Design & Development

- Ship Construction

- Operation & Maintenance

- Customized Modification

-

FreeScan Trak ProW

FreeScan Trak ProW maintains core features such as marker-free scanning and guaranteed high accuracy of the FreeScan Trak Pro series, while introducing advanced upgrades for improved performance.

-

Scan Accuracy

0.023 mm -

Volumetric Accuracy

15.6 m³: 0.046 mm; 45 m³: 0.063 mm; 76 m³: 0.088 mm; 128 m³: 0.127 mm -

Scan Speed

5,500,000 points/s -

Point Distance

0.01 ~ 10 mm -

Maximum FOV

/ -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser -

Align Mode

Feature Alignment / Marker Alignment

-

-

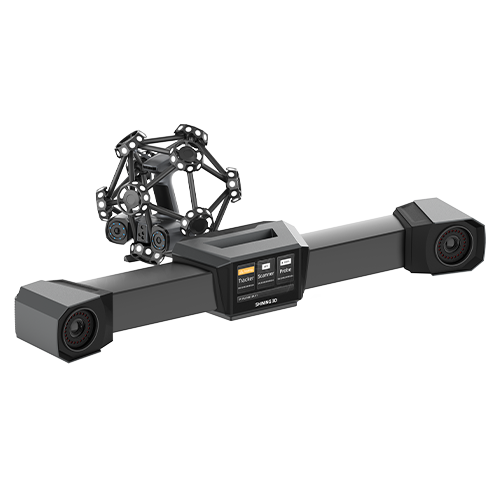

FreeScan Trak Nova

FreeScan Trak Nova integrates a portable tracking scanner, the largest-FOV handheld laser scanner, and video photogrammetry (VPG) module into one advanced wireless tracking system.

-

Scan Accuracy

0.02 mm -

Volumetric Accuracy

0.062 mm (12 m³) -

Scan Speed

6,140,000 points/s -

Point Distance

0.01 ~ 10 mm -

Maximum FOV

2600 x 2200 mm -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser -

Align Mode

Feature Alignment / Marker Alignment

-

-

FreeScan UE Pro2

FreeScan UE Pro2 is a wireless 3D scanner with ultra-fast speed. Its versatile scan modes and light weight make it ideal for on-site inspections.

-

Scan Accuracy

-

Volumetric Accuracy

0.02 + 0.015 mm/m

-

Scan Speed

3,460,000 points/s

-

Point Distance

0.01 ~ 10 mm

-

Maximum FOV

600 x 550 mm

-

Material Adaptability

Normal / Dark / Reflective

-

Type of light source

Laser

-

Align Mode

Marker Alignment

-

-

FreeScan Combo Series

Entry-level metrology handheld scanner with a combination of blue laser and infrared light for diverse industrial 3D scanning scenarios.

-

Scan Accuracy

0.02 mm -

Volumetric Accuracy

0.02 + 0.033 mm/m -

Scan Speed

3,600,000 points/s (FreeScan Combo+)

1,860,000 points/s (FreeScan Combo)

-

Point Distance

0.05 ~ 10 mm -

Maximum FOV

520 x 510 mm -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser + Infrared VCSEL -

Align Mode

Feature Alignment / Marker Alignment

-

-

EinScan Libre

The EinScan Libre delivers a fully wireless, standalone 3D scanning experience, powered by its built-in screen and NVIDIA processor.

-

Scan Accuracy

/ -

Volumetric Accuracy

0.04 + 0.06mm/m -

Scan Speed

2,700,000 points/s (IR Rapid); 1,900,000 points/s (IR Adaptive); 4,500,000 points/s (Laser HD)

-

Point Distance

0.5 ~ 10 mm (IR Rapid/IR Adaptive); 0.05 ~ 3 mm (Laser HD) -

Maximum FOV

983 x 979 mm (IR Rapid); 779 x 835 mm (IR Adaptive); 382 x 450 mm (Laser HD) -

Material Adaptability

Normal / Dark / Reflective / Outdoor -

Type of light source

IR VCSEL / IR Laser / Blue Laser -

Align Mode

Markers/Global Markers/Feature/Texture/Hybrid(IR Rapid/Laser HD); Markers/Global Markers(IR Adaptive)

-

Trusted Worldwide

Let's explore why SHINING 3D is the go-to choice for experts across various industries.

-

Marine

Digitally Repairing and Restoring...

-

Engineering Machinery & Other Transportation

How High-Accuracy 3D Scanning...

-

Engineering Machinery & Other Transportation

3D Scanning Yachts for Custom...

-

Marine

3D Scanning Propeller: A Highly...

-

Engineering Machinery & Other Transportation

3D Scanning and Reverse Engineering for...