CASE STUDIES

Published on May. 12th 2025

SHINING 3D’s Diverse Scanning Solutions Empower Smarter Quality Control at Dawn Precision

Enhance manufacturing accuracy with optical 3D metrology. See how Dawn Precision uses SHINING 3D’s scanning solutions for smarter quality control.

About Dawn Precision

Dawn Precision is a large manufacturer of pulleys and bushings and other mechanical transmission components, and has led the industry in export volume for years.

With a fully integrated production system encompassing forging and casting, machining, heat treatment, assembly, and warehousing, Dawn Precision is well-equipped to meet the growing demand for diversified, small-batch, and customized orders. This complexity also brings a wide range of measurement and inspection challenges across different manufacturing stages.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

High-Accuracy 3D Scanning in Different Production Stages

To meet the demands of increasingly diversified production and ensure high product quality, Dawn Precision introduced SHINING 3D’s optical 3D metrology. With a wide variety of parts and complex manufacturing processes, the company now leverages 3D scanning for efficient full-field inspection and machining allowance control across different production stages and product types.

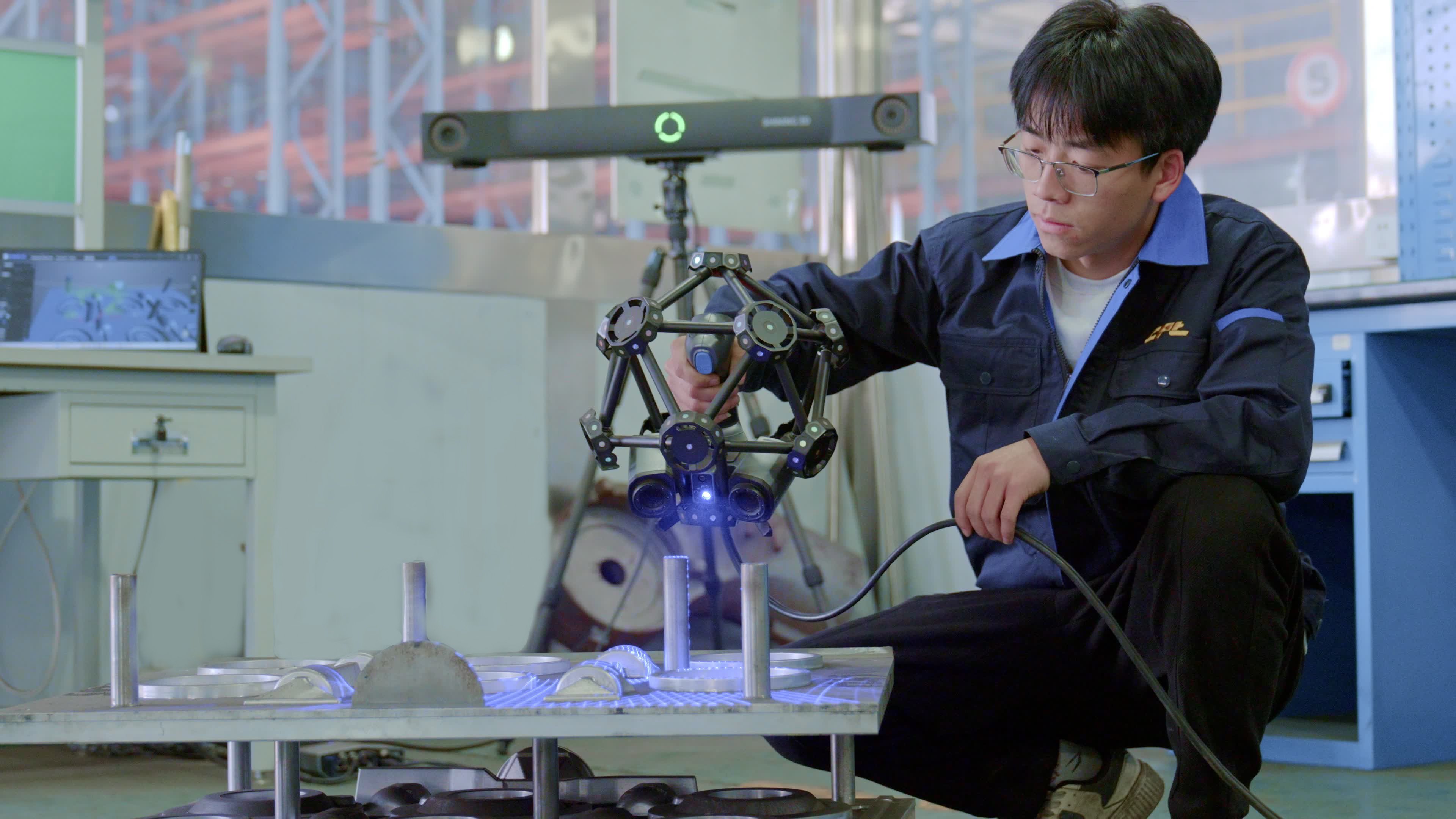

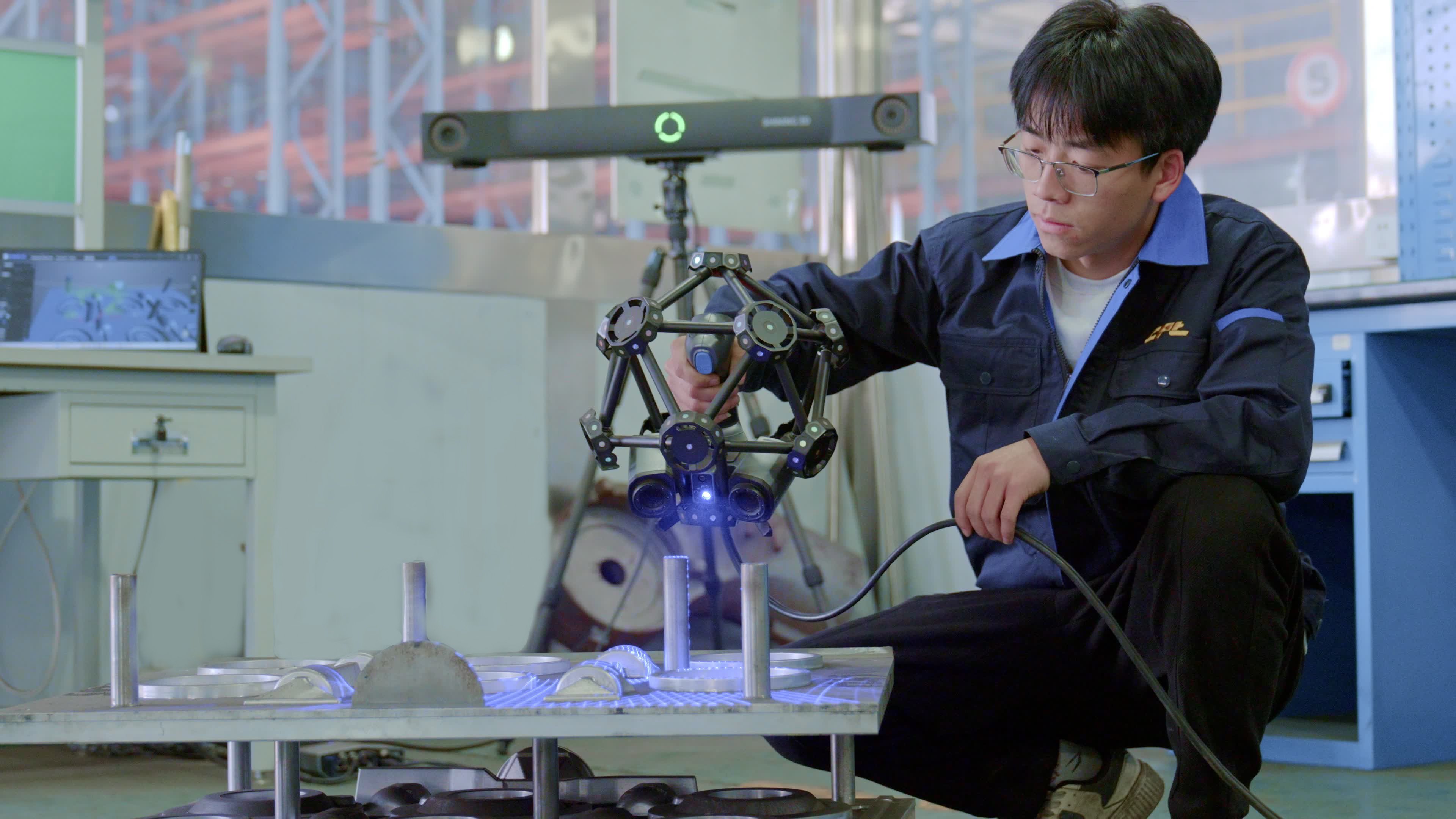

Fast, marker-free scanning for casting inspection

In the casting stage, Dawn Precision uses SHINING 3D’s FreeScan Trak Pro2 to inspect casting patterns, molds, and blanks—ensuring dimensional accuracy and sufficient machining allowance. The marker-free dynamic tracking system enables fast, full-size scans, with 3D-to-CAD comparison offering a clear view of excess material.

Scan a casting mold with FreeScan Trak Pro2

Scan a casting mold with FreeScan Trak Pro2

Fixed scanning for dimensional accuracy

In precision machining, maintaining tight dimensional tolerances is critical. Dawn Precision utilizes OptimScan 5M Plus, a high-precision 3D inspection system, to perform full-field inspections on finished parts. With high accuracy up to 0.005 mm, it enables high-accuracy measurement and strengthens dimensional quality control.

Scan a locking assembly with OptimScan 5M Plus

“We chose SHINING 3D for its comprehensive product range and reliable quality. Whether we're scanning workpieces in confined spaces or inspecting large-scale parts, SHINING 3D’s scanners are well-suited to the demands of our production line environment.”

- Xu Jie, Technical Engineer of Dawn Precision

Why 3D Scanning Transforms Quality Control

Significantly improved efficiency

- A casting part that used to take over an hour for manual inspection can now be fully scanned and analyzed in around 20 minutes using FreeScan Trak Pro2 — boosting efficiency by 67%.

- 3D scanners allow for on-site inspection directly in the workshop, no need to moving big parts to a specific measurement room.

User-friendly operation

- SHINING 3D’s intuitive software interface makes the system easy to learn and operate, minimizing reliance on highly skilled technicians and reducing labor costs.

- Portable and flexible, 3D scanners can be easily deployed across different production areas, adapting to various inspection tasks without the need for a fixed setup.

A Smarter Path to Better Quality Control

By integrating high-accuracy 3D scanning solutions into its production workflow, Dawn Precision has significantly enhanced inspection efficiency, optimized resource allocation, and strengthened quality control. As manufacturing demands continue to grow, smart, reliable tools like SHINING 3D’s scanners are becoming key drivers of sustainable growth and competitive advantage.

Looking to streamline your quality control process? Get free consultation from our experts.

FreeScan Trak Pro2

With high precision and repeatability, the FreeScan Trak Pro2 allows for fast, accurate inspection of various part types and surfaces without the need for markers. It is the ideal metrology tool for quality control and 3D inspection.

- No Markers Needed

- Exceptional Accuracy

- Wide Measuring Range