CASE STUDIES

Published on Sep. 8th 2025

3D Scanning and Casting Helped Ford Restore a Forgotten Detroit Landmark

Discover how SHINING 3D’s scanning and casting restored Michigan Central Station’s iconic railings, blending heritage with modern innovation.

Background: A Landmark Revived

Michigan Central Station, originally built in 1913 in the elegant Beaux-Arts style, was once among America’s grandest train terminals. Designed by the same architectural firms behind New York’s Grand Central, it symbolized Detroit’s early 20th-century prominence.

Closed in 1988 and left to decay, it became an emblem of urban decline until Ford Motor Company purchased the derelict structure in 2018. Over a six-year, nearly $1 billion restoration—including the station and its surrounding Corktown campus—Ford transformed it into a cutting-edge tech and cultural district.

In June 2024, the station reopened amid fanfare, hosted a sold-out concert featuring Detroit legends such as Diana Ross and Jack White, and became the anchor of the revitalized Michigan Central Innovation District. The restored Grand Hall, façades, vaulted ceilings, and retail spaces now stand as a testament to Detroit’s resurgence.

.webp)

Before and After the Restoration of Michigan Central Station

Restoring Historic Cast-Iron Handrail Caps

Among the countless architectural details needing restoration were the ornate cast-iron handrail lining the station’s platform staircases. Most originals were deteriorated, yet their designs were integral to the building’s character. The intricate patterns on the handrail cap present a significant challenge to replicate. Many local foundry and pattern shops were hired to complete this restoration project, and on many parts they used 3D scanning and reverse engineering technologies.

Damaged stair handrail post caps

How to Revive a Century-Old Design

3D Scanning the Originals and Reverse Engineering

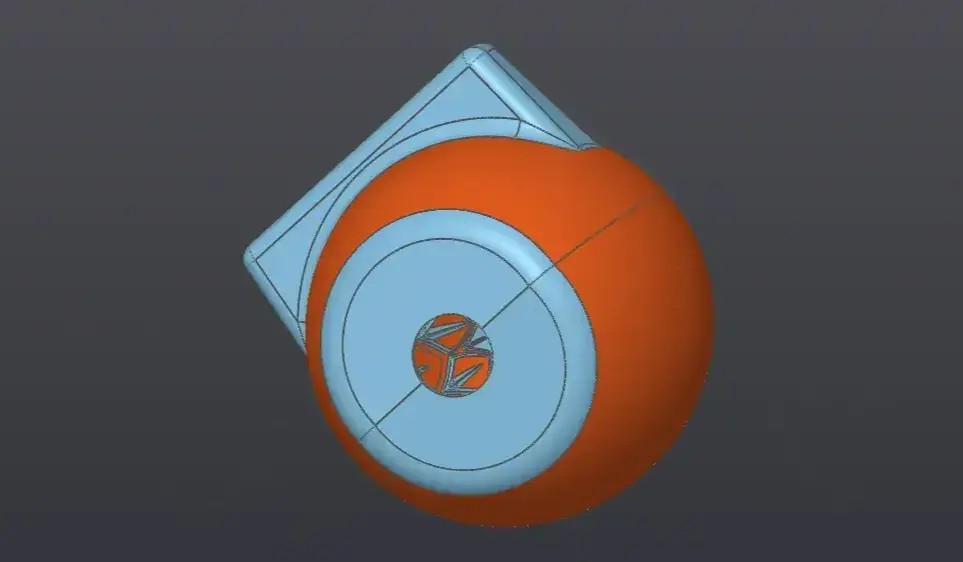

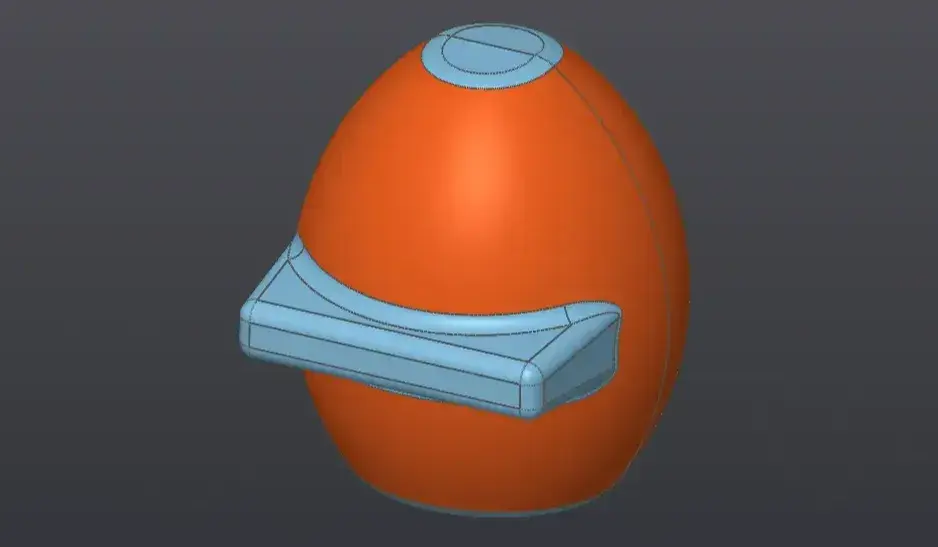

JJ Pattern, a local pattern shop, used a combination of traditional pattern building techniques, 3D scanning, and 3D printed sand cores. Preferred Technologies LLc used SHINING 3D’s FreeScan UE Pro2 laser handheld 3D scanner, to capture several cast parts including the iron filigree florets in the train station. Every ornamental motif was recorded, preserving the geometry of the 1913 design. The scan data was imported into CAD software, where CAD designers reconstructed the complete model of the cap, including the detail of the top or finial.

.png?width=778&height=438&name=Screenshot%202025-05-23%20140131(1).png)

Reverse-engineered 3D model of the cap

3D model of the finial sand core

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

Wooden Patterns, Sand Mold, and Casting

To create the sand mold, CNC machining was used to fabricate high density polyurethane base pattern. The finial mold core 3D printed sand, and placed into the base pattern at the foundry before casting the bronze part.

CNC-machined wooden patterns

The final wooden pattern for making sand molds

With the sand mold assembled, molten bronze was poured into it through a gating system. Once cooled and solidified, the sand is broken away, revealing the newly cast handrail cap components. Then, the raw castings were cleaned and machined. Approximately 200 new caps were successfully cast.

The original casting components after the sand mold is removed

Installed handrail caps

Impact and Significance

This restoration ensures that the newly cast railings faithfully reflect the artistry and detail of the originals, producing 200 pieces that are historically authentic yet durable for modern use. The return of these railings restored spatial continuity and visual integrity within the station. As part of the larger revival, they embody both the grandeur of Detroit’s past and the innovative spirit shaping its future, making them a vital element in the rebirth of this landmark.

FreeScan UE Pro2

FreeScan UE Pro2 is a wireless multi-functional laser handheld 3D scanner, ideal for inspection and versatile applications. It streamlines your workflow effortlessly with all-in-one shopfloor solution, setting a new standard in portable 3D metrology world.

- WIRELESS

- Ultra-fast scan speed up to 3,460,000 points/s

- Patented binocular photogrammetry

- Quick on-site inspection