Engineering Machinery & Other Transportation

SHINING 3D provides essential benefits to the Engineering Machinery & Other Transportation industry. Our precise 3D measurements improve quality control, reduce errors, and cut costs. Our scanners enable efficient reverse engineering, rapid part development, and quick identification of wear and damage, minimizing downtime. We also support digital documentation for better traceability and compliance. Overall, our scanners enhance efficiency, cost-effectiveness, and innovation in the industry.

Overview

About Our Metrology Solutions

SHINING 3D offers higher accuracy and greater efficiency.

Engineering Machinery Solutions

Integrated equipment for loading/unloading, construction, and maintenance

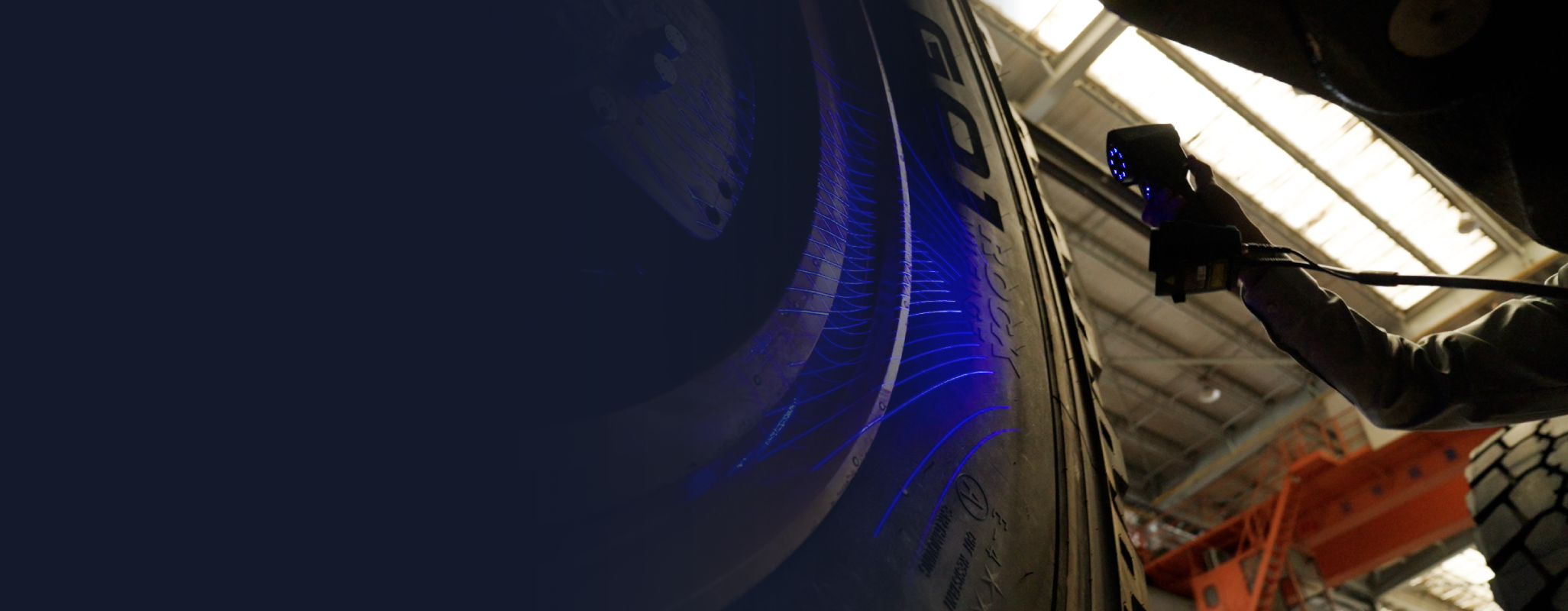

SHINING 3D scanners can enhance Engineering Machinery Solutions by providing precise 3D scanning for parts and equipment. This enables accurate measurements, quality control, and efficient reverse engineering. Benefits include improved maintenance planning, reduced downtime, and streamlined manufacturing processes through rapid prototyping and custom part development.

Advancing Ship and Port Operations through 3D Inspection and Maintenance

SHINING 3D scanners contribute to the maritime and port industries by providing accurate 3D scanning capabilities for inspection and maintenance tasks. This technology ensures precise measurements, enhances quality control, and facilitates efficient repairs. Benefits include expedited diagnosis of issues, minimized downtime, and enhanced safety compliance through detailed digital documentation and analysis.

Rail Transit

High-speed trains, bullet trains, subways, light rail

SHINING 3D scanners can significantly benefit rail transit systems like high-speed trains, bullet trains, subways, and light rail by providing precise 3D scanning capabilities. Our scanners enable accurate measurement of components, efficient maintenance planning, and quality control. Benefits include faster identification of wear and damage, reduced downtime for repairs, and improved safety through thorough inspection and analysis of critical parts.

What You Can Achieve with Our Scanners

Discover the ways in which integrating our scanners into your workflow can enhance efficiency and help you achieve remarkable results.

-

Production Control

Our 3D scanners are utilized in production control to ensure parts and assemblies meet precise specifications, enabling real-time quality assurance and reducing manufacturing errors.

-

Train Maintenance

Our 3D scanners are used to inspect and document the condition of train components, identifying wear, damage, and alignment issues to ensure timely and accurate repairs, thus enhancing safety and performance.

-

Ship Building Quality Control

Our 3D scanners are employed to verify the dimensional accuracy of hulls and components, detect surface defects, and ensure precise alignment, thereby enhancing the overall quality and integrity of the ship construction process.

-

Reverse Engineering

Our 3D scanners are used in reverse engineering to create accurate digital models of existing parts and assemblies, enabling the reproduction of obsolete components and the analysis of competitor designs for innovation and improvement.

-

Vibration Analysis

Our 3D scanners play a crucial role in vibration analysis by providing detailed geometric data of components. This allows engineers to simulate and analyze vibration behavior, identify potential issues early, and optimize designs for enhanced performance and durability.

-

Shape and Dimension Control

Our 3D scanners are utilized for shape and dimension control to ensure that components conform to precise design specifications, facilitating accurate measurements and early detection of manufacturing deviations.

-

FreeScan Trak ProW

FreeScan Trak ProW maintains core features such as marker-free scanning and guaranteed high accuracy of the FreeScan Trak Pro series, while introducing advanced upgrades for improved performance.

-

Scan Accuracy

0.023 mm -

Volumetric Accuracy

15.6 m³: 0.046 mm; 45 m³: 0.063 mm; 76 m³: 0.088 mm; 128 m³: 0.127 mm -

Scan Speed

5,500,000 points/s -

Point Distance

0.01 ~ 10 mm -

Maximum FOV

/ -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser -

Align Mode

Feature Alignment / Marker Alignment

-

-

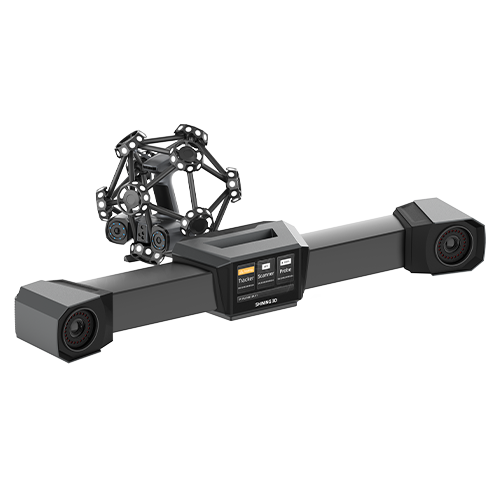

FreeScan Trak Nova

FreeScan Trak Nova integrates a portable tracking scanner, the largest-FOV handheld laser scanner, and video photogrammetry (VPG) module into one advanced wireless tracking system.

-

Scan Accuracy

0.02 mm -

Volumetric Accuracy

0.062 mm (12 m³) -

Scan Speed

6,140,000 points/s -

Point Distance

0.01 ~ 10 mm -

Maximum FOV

2600 x 2200 mm -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser -

Align Mode

Feature Alignment / Marker Alignment

-

-

FreeScan Omni Series

FreeScan Omni is world's first standalone inspection-ready metrology 3D scanner.

-

Scan Accuracy

0.02 mm -

Volumetric Accuracy

0.02 + 0.03 mm/m -

Scan Speed

7,619,000 points/s -

Point Distance

0.01 ~ 10 mm -

Maximum FOV

580 x 650 mm -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser + Infrared VCSEL -

Align Mode

Feature Alignment / Marker Alignment

-

-

FreeScan UE Nova

FreeScan UE Nova, a wide-range wireless laser handheld 3D scanner, sets the new standard in 3D scanning with its unmatched field of view

-

Scan Accuracy

0.072 mm -

Volumetric Accuracy

0.072 + 0.012 mm/m -

Scan Speed

4,600,000 point/s -

Point Distance

0.5 ~ 10 mm

-

Maximum FOV

2600 x 2200 mm -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser -

Align Mode

Feature Alignment / Marker Alignment

-

-

FreeScan UE Pro2

FreeScan UE Pro2 is a wireless 3D scanner with ultra-fast speed. Its versatile scan modes and light weight make it ideal for on-site inspections.

-

Scan Accuracy

0.02 mm

-

Volumetric Accuracy

0.02 + 0.015 mm/m

-

Scan Speed

3,460,000 points/s

-

Point Distance

0.01 ~ 10 mm

-

Maximum FOV

600 x 550 mm

-

Material Adaptability

Normal / Dark / Reflective

-

Type of light source

Laser

-

Align Mode

Marker Alignment

-

-

FreeScan Combo Series

Entry-level metrology handheld scanner with a combination of blue laser and infrared light for diverse industrial 3D scanning scenarios.

-

Scan Accuracy

0.02 mm -

Volumetric Accuracy

0.02 + 0.033 mm/m -

Scan Speed

3,600,000 points/s (FreeScan Combo+)

1,860,000 points/s (FreeScan Combo)

-

Point Distance

0.05 ~ 10 mm -

Maximum FOV

520 x 510 mm -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser + Infrared VCSEL -

Align Mode

Feature Alignment / Marker Alignment

-

-

EinScan Libre

The EinScan Libre delivers a fully wireless, standalone 3D scanning experience, powered by its built-in screen and NVIDIA processor.

-

Scan Accuracy

/ -

Volumetric Accuracy

0.04 + 0.06mm/m -

Scan Speed

2,700,000 points/s (IR Rapid); 1,900,000 points/s (IR Adaptive); 4,500,000 points/s (Laser HD)

-

Point Distance

0.5 ~ 10 mm (IR Rapid/IR Adaptive); 0.05 ~ 3 mm (Laser HD) -

Maximum FOV

983 x 979 mm (IR Rapid); 779 x 835 mm (IR Adaptive); 382 x 450 mm (Laser HD) -

Material Adaptability

Normal / Dark / Reflective / Outdoor -

Type of light source

IR VCSEL / IR Laser / Blue Laser -

Align Mode

Markers/Global Markers/Feature/Texture/Hybrid(IR Rapid/Laser HD); Markers/Global Markers(IR Adaptive)

-

Trusted Worldwide

Let's explore why SHINING 3D is the go-to choice for experts across various industries.

-

Engineering Machinery & Other Transportation

Inside Steelstruct: Using SHINING 3D...

-

Engineering Machinery & Other Transportation

How High-Accuracy 3D Scanning...

-

Engineering Machinery & Other Transportation

3D Scanning Yachts for Custom...

-

Engineering Machinery & Other Transportation

FreeScan Combo Helps Reduce Costs and...

-

Industrial Design & Services

H7 Metrology: Efficient Reverse...