0.02 mm

Civil Aviation

Manufacturing complex structural components of aircraft is challenging. SHINING 3D scanners facilitate the efficient capture of 3D models for reverse engineering and inspection, providing robust solutions for the mass production of complex and customized parts.

Overview

3D Scanning in Civil Aviation

Compared to conventional measurement tools, 3D scanning offers:

High Accuracy

Blue light scanner: up to 0.005 mm

Handheld laser scanner: up to 0.02 mm

High Versatility

Easily scan complex geometries and diverse materials.

High Efficiency

Rapidly acquire millions of data points, significantly reduce inspection time

Non-Contact Measurement

NDT safely measures hot parts (like post-operation engines) and delicate surfaces

Portability

Unrestricted by environment, convenient to carry, and easy to operate

Automation

Can be integrated with robots to achieve automated inspection

High-Accuracy 3D Scanning in Civil Aviation Applications

R&D and Design

Manufacturing

Enhance Quality Control with high-speed inspection. Verify CAD compliance for critical parts like turbine blades, combustion chambers, inlet housings, and landing gear panels, ensuring manufacturing reliability and reducing scrap.

Flight Testing

Validate flight test articles by capturing precise as-built geometry of airframes and control surfaces. This data is critical for accurate flight parameter analysis, design validation, and aerodynamic improvements.

Maintenance, repair, and overhaul (MRO)

Accelerate MRO workflows and minimize aircraft downtime. Rapidly perform accurate damage assessment (dents, wear, corrosion) on airplane skin, fuselage or engine blades, supporting fast, traceable airworthiness decisions.

Our Metrology Solutions for Civil Aviation

.jpg?width=2000&name=Aircraft%20maintenance%20hangar%20(20).jpg)

Aero Engines

Perform high-precision inspection, reverse engineering, and QC for complex engine components. Our non-contact scanners easily capture metrology-grade data from turbine blades, engine piping, and combustion chambers. Multiple laser line modes are designed to capture deep holes and intricate features with ease, ensuring complete validation.

Aircraft & Airframes

Ideal for large-scale industrial metrology of airframes, fuselage sections, and wing structures. Our optical tracking 3D scanners capture data rapidly without needing target points, significantly reducing setup time. Equipped with blue laser technology, they efficiently handle high-contrast, reflective, and dark surfaces with high accuracy.

Surface Inspection

Precisely identify and quantify surface defects, imperfections, and irregularities for both QC and MRO. Rapidly measure dents, wear, or corrosion on the airplane skin or fuselage. This quantitative data accelerates repair decisions, ensures airworthiness, and minimizes costly aircraft downtime.

Strategic Partnership with LOONG AIR in Civil Aviation Maintenance

"This collaboration marks a pivotal move in the digital-intelligent transformation of civil aviation maintenance. It will not only enhance our operational efficiency but also set an industry benchmark for innovative practices."

Yang Suili, Chairman of LOONG TECHNIC

What You Can Achieve with Our Scanners

Discover the ways in which integrating our scanners into your workflow can enhance efficiency and help you achieve remarkable results.

-

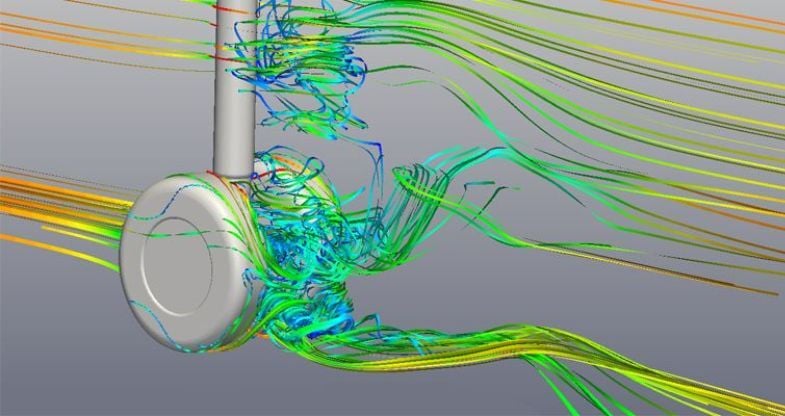

Wind Tunnel Testing

Our metrology-grade 3D scanners can capture complete model geometry, enabling wind tunnel simulations in software—faster and more cost-effective.

-

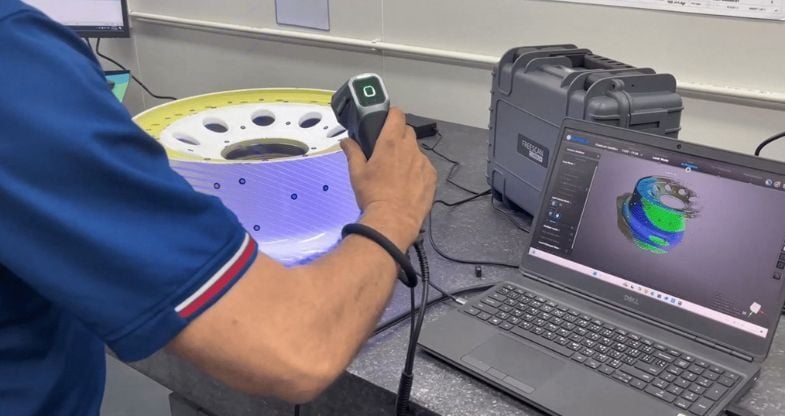

Blade Inspection

Our 3D scanners are used to accurately measure and analyze the geometry of turbine blades, identifying surface defects, wear, and deformation to ensure optimal performance and safety.

-

Structural Inspection

Our 3D scanners are utilized to create detailed digital models of aircraft structures, allowing for the precise detection of cracks, corrosion, and deformations to ensure structural integrity and safety.

-

Model Aircraft Production

Before actual flight testing, free-flight model tests are conducted to simulate aircraft performance and reduce risk. High-accuracy 3D scanning captures complete geometry for efficient model manufacturing.

-

Aircraft Maintenance

After damage occurs, many aircraft parts—often non-standard—require fast and accurate reproduction. Our high-accuracy 3D scanners enable quick data capture of damaged components, supporting rapid manufacturing of custom replacement parts.

-

Component Design

Our high-accuracy 3D scanners capture precise geometries for reverse engineering and design refinement, accelerating iteration and innovation.

-

Manufacturing Inspection

Our 3D scanners are used to verify the dimensional accuracy and quality of manufactured parts, ensuring they meet design specifications and identifying any deviations or defects early in the production process.

-

Aircraft Inspection

Our 3D scanners are employed to accurately capture the geometry of interior spaces, ensuring proper fit and alignment of components, and identifying wear or damage for maintenance and refurbishment.

-

Flight Parameters Calculation

After flight tests, 3D scanners provide fast and accurate aircraft shape data to support flight analysis and design improvements.

-

Aircraft Repair

Post-flight inspections may reveal structural damage. Our 3D scanners can help assess the severity of the damage efficiently, supporting timely decisions on airworthiness and whether grounding for repair is necessary.

-

FreeScan Trak Nova

FreeScan Trak Nova integrates a portable tracking scanner, the largest-FOV handheld laser scanner, and video photogrammetry (VPG) module into one advanced wireless tracking system.

-

Scan Accuracy

0.02 mm -

Volumetric Accuracy

0.062 mm (12 m³) -

Scan Speed

6,140,000 points/s -

Point Distance

0.01 ~ 10 mm -

Maximum FOV

2600 x 2200 mm -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser -

Align Mode

Feature Alignment / Marker Alignment

-

-

FreeScan UE Pro2

FreeScan UE Pro2 is a wireless 3D scanner with ultra-fast speed. Its versatile scan modes and light weight make it ideal for on-site inspections.

-

Scan Accuracy

-

Volumetric Accuracy

0.02 + 0.015 mm/m

-

Scan Speed

3,460,000 points/s

-

Point Distance

0.01 ~ 10 mm

-

Maximum FOV

600 x 550 mm

-

Material Adaptability

Normal / Dark / Reflective

-

Type of light source

Laser

-

Align Mode

Marker Alignment

-

-

OptimScan Q12

OptimScan Q12 is a high-precision 3D scanner with 4 × 12.3 megapixel cameras. It supports two scan ranges, allowing users to switch between them with a single click.

-

Scan Accuracy

Large range: 0.015 mm; Small range: 0.005 mm -

Volumetric Accuracy

/ -

Scan Speed

/ -

Point Distance

Large range: 0.1 mm; Small range: 0.04 mm -

Maximum FOV

Large range: 430 × 300 mm; Small range: 160 × 110 mm -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Blue LED -

Align Mode

Feature / Markers / Global Markers / Hybrid / Turntable

-

-

FreeScan UE Pro

Professional metrology handheld scanner with 26+7+1 blue laser lines and built-in photogrammetry for scanning different sizes and global precision control of large-scale workpieces.

-

Scan Accuracy

0.02 mm -

Volumetric Accuracy

0.02 + 0.015 mm/m -

Scan Speed

1,850,000 points/s -

Point Distance

0.01 ~ 10 mm -

Maximum FOV

600 x 550 mm -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser -

Align Mode

Marker Alignment

-

-

OptimScan 5M Plus

Blue light, high-precision 3D scanner for inspection, with 3 sets of lenses for flexible range switching.

-

Scan Accuracy

0.005 ~ 0.015 mm -

Volumetric Accuracy

/ -

Scan Speed

/ -

Point Distance

0.04 ~ 0.16 mm -

Maximum FOV

100 x 75 / 200 x 150 / 400 x 300 mm

-

Material Adaptability

Normal / Dark / Reflective -

Type of light source

LED -

Align Mode

Feature Alignment / Marker Alignment

-

-

FreeScan Trak Pro2

A metrology-grade optical tracking 3D scanning system for medium and large objects without markers. It is suitable for various static and dynamic applications.

-

Scan Accuracy

0.023 mm -

Volumetric Accuracy

0.062 mm -

Scan Speed

3,070,000 points/s -

Point Distance

0.05 ~ 10 mm -

Maximum FOV

650 x 580 mm -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser -

Align Mode

Feature Alignment / Marker Alignment

-

-

FreeScan Trio

Flagship metrology handheld scanner with fast and innovative 98 laser lines for marker-free scanning. Whether you need speed or accuracy on small or large assemblies, the versatile FreeScan Trio is geared for all your projects.

-

Scan Accuracy

0.02 mm -

Volumetric Accuracy

0.02 + 0.015 mm/m -

Scan Speed

3,010,000 points/s -

Point Distance

0.01 ~ 3 mm -

Maximum FOV

650 x 580 mm -

Material Adaptability

Normal / Dark / Reflective -

Type of light source

Laser -

Align Mode

Feature Alignment / Marker Alignment

-

Trusted Worldwide

Let's explore why SHINING 3D is the go-to choice for experts across various industries.