CASE STUDIES

Published on Nov. 4th 2022

Revolutionizing Aerospace MRO: FreeScan UE Pro Delivers High-Accuracy Aircraft Damage Assessment

Explore how a civil aviation MRO team replaced slow, subjective manual inspections with the SHINING 3D FreeScan UE Pro handheld 3D scanner to achieve fast, metrology-grade measurements for critical aircraft damage.

Introduction: The High-Stakes Challenge of Aircraft MRO

In the civil aviation industry, safety is non-negotiable. Maintenance, Repair, and Overhaul (MRO) teams are under immense pressure to accurately assess aircraft structural integrity while minimizing costly Aircraft on Ground (AOG) time.

One of the most common challenges is inspecting structural damage like dents, gouges, and holes caused by bird strikes or Foreign Object Debris (FOD). Before an aircraft can be cleared for its next flight, engineers must precisely measure the extent of this damage to determine if it falls within acceptable structural limits.

Airplane Dent

Airplane Dent

The Bottleneck:

Traditional Inspection Methods

For years, MRO engineers relied on traditional manual measurement techniques, such as the "grid method." This process involves:

- Drawing a grid over the damaged area.

- Using depth gauges and calipers to measure points manually.

- Estimating the total damage area and depth based on these limited data points.

This conventional approach presented two significant problems:

- Subjective and Inaccurate: The results were heavily dependent on the engineer's skill and experience, leading to inconsistent and subjective estimations rather than objective, repeatable data.

- Highly Inefficient: The process of drawing grids and taking manual measurements was extremely time-consuming, creating a bottleneck that directly delayed aircraft release and increased operational costs.

The Solution: High-Efficiency, Metrology-Grade 3D Scanning

To overcome these challenges, a forward-thinking MRO provider integrated the SHINING 3D FreeScan UE Pro laser handheld 3D scanner into its quality control workflow.

FreeScan UE Pro is a metrology-grade, portable 3D scanning system designed for high-accuracy industrial inspection. The new workflow is simple, fast, and precise:

On-Ramp Scanning: An engineer takes the lightweight, portable FreeScan UE Pro directly to the aircraft—whether on the tarmac or in the hangar.

Rapid Data Capture: The scanner is used to quickly capture the complete 3D geometry of the damaged area, such as the fuselage skin, engine inlet lip, or wing leading edge. The scanner operates without needing to affix markers for most scans and captures up to 2,100,000 points per second.

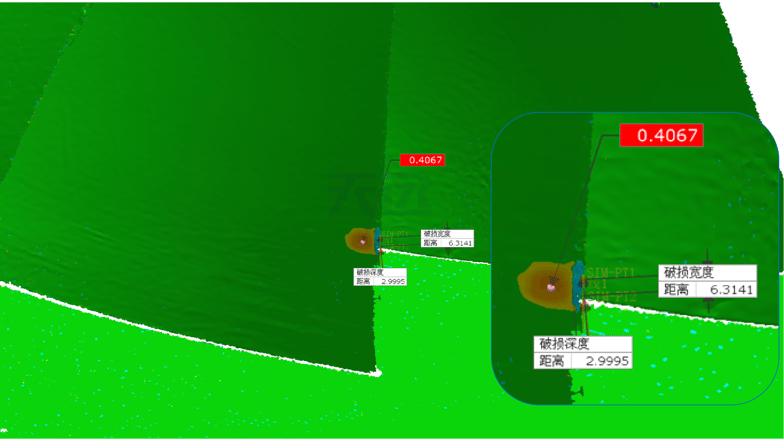

Data Analysis: The high-resolution 3D data is imported into inspection software. By comparing the scan data against the original CAD model (or a reference surface reconstructed from the surrounding undamaged area), engineers can instantly and accurately measure the precise width, depth, and volume of the damage.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

The Results: A New Standard in Airworthiness Assessment

The adoption of the FreeScan UE Pro 3D scanner fundamentally transformed the MRO team's damage assessment capabilities, delivering immediate and measurable benefits.

1. Objective, Metrology-Grade Accuracy

Subjective guesswork was eliminated. The FreeScan UE Pro provides a volumetric accuracy of up to 0.02 + 0.015 mm/m, ensuring that every measurement is precise and reliable. This objective data allows engineers to make airworthiness decisions with complete confidence, knowing the data is accurate and repeatable, regardless of which operator performs the scan.

2. Drastic Reduction in Inspection Time

What once took hours of meticulous manual work is now completed in minutes. For example, a complete scan of a damaged Boeing 737 engine inlet lip now takes just over 10 minutes. This massive reduction in inspection time directly shortens aircraft turn-around time (TAT), allowing planes to be safely returned to service faster.

3. Enhanced Workflow and Portability

The handheld, lightweight design of the FreeScan UE Pro means inspections can be performed anywhere. Critically, parts do not need to be disassembled from the aircraft. This on-wing inspection capability saves countless hours of maintenance labor and logistical complexity, further streamlining the entire MRO process.

By integrating the SHINING 3D FreeScan UE Pro, the MRO provider successfully solved its most significant inspection bottlenecks. The solution replaced a slow, inaccurate, and subjective process with one that is fast, objective, and delivers metrology-grade accuracy. This adoption of 3D scanning technology not only enhances operational efficiency but, most importantly, provides a more reliable foundation for the critical safety and airworthiness decisions that define the civil aviation industry.

FreeScan UE Pro

FreeScan UE Pro equips high-precision, metrology-grade accuracy and a lightweight design while improving the ability to fine-scan and global precision control large-scale workpiece scanning.

- Metrology-Grade High Accuracy

- Global Precision Control

- Multiple Scanning Modes