Case Studies

Published on Jan. 30th 2026

Digitizing Centuries-Old Craft: How 3D Scanning Transforms Traditional Woodcarving and Bronze Casting

Discover how to overcome parts development and performance improvement challenges in the Audi Sport Quattro racing car using 3D scanning technology.

In Vietnam’s craft villages, centuries-old woodcarving and bronze casting traditions face modern challenges: time-consuming manual production, high costs, and difficulties in preserving intricate details. Enter 3D scanning, a technology that bridges tradition and innovation, offering craft villages a way to digitize and revitalize their heritage. Through the stories of two practitioners from Nam Dinh province, this case study explores how 3D scanning technology is reshaping traditional crafts while preserving their cultural essence.

Two Crafts, One Shared Turning Point

Bronze Casting: Preserving What Time Erases

Trained as a manufacturing engineer, Lộc understood early on that traditional bronze casting struggled with one key limitation: once a detail was lost, it was almost impossible to recover. Complex ornaments, weathered relics, and damaged molds, many could not be faithfully reproduced using manual methods alone.

When Lộc first encountered modern handheld 3D scanners, the shift was immediate. What once depended on craftsmanship alone could now be captured as precise digital data. For the first time, bronze artifacts could be preserved before time erased them.

Woodcarving: Breaking the Time Barrier

In Hải Minh craft village, Nguyễn Văn Lượng faced a different problem.

His workshop produced high-end antique-style wooden furniture, but every new design started the same way: carving a physical model by hand. A single prototype could take over a week before production even began. As orders increased, the math no longer worked.

By integrating 3D scanning into his workflow, Lượng fundamentally changed how designs were created. Existing pieces could be digitized within hours, adjusted digitally, and prepared directly for CNC carving without sacrificing artistic detail. Time was no longer the bottleneck.

Using the EinScan Pro series, both artisans achieved something previously out of reach:

-

Accurate digital archiving of heritage objects

-

Reverse engineering for damaged or incomplete pieces

-

Digital manufacturing

- Shorter production cycles

- Lower costs

- Higher accuracy consistency and quality

- Long-term preservation of cultural detail

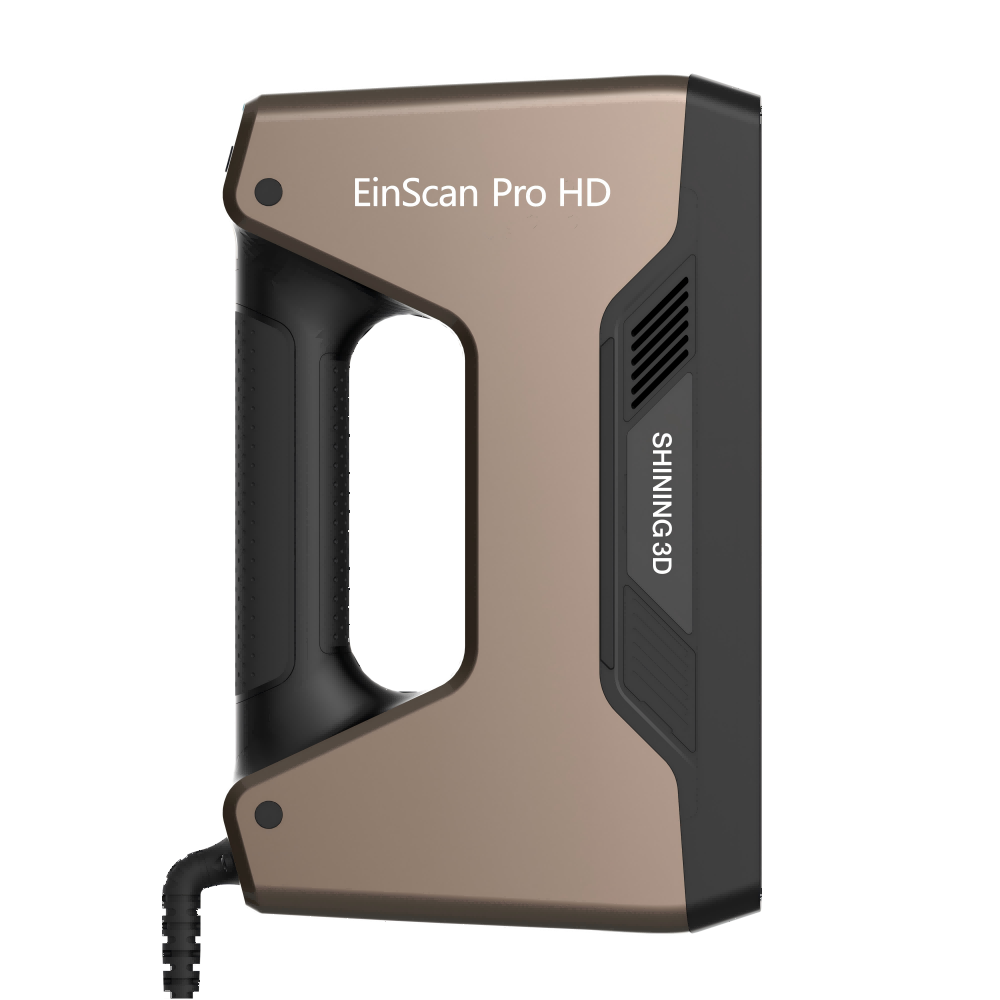

EinScan Pro HD

The EinScan Pro HD offers top-notch handheld scanning with high resolution and accuracy, perfect for designers and engineers. Its versatile design ensures reliability and efficiency in professional-grade 3D modeling.

-

Impressive high resolution and high accuracy

-

Scan speed up to 3,000,000 points/s

-

Handle dark and casting metal surface with less limitations

-

WorldSkills designated competition model