CASE STUDIES

Published on May. 28th 2020

Custom Orthotics Through 3D Scanning with EinScan Pro 2X Plus

OT4, an innovative orthopedics company from southern Germany uses the EinScan Pro 2X Plus to create custom orthotics.

3D digitizing technologies are used in a broad range of different applications from Product Design, Engineering and Art to applications in the Medical Industry. A very popular and successful approach of using the technology is the deployment of custom orthotics. SHINING 3D has been working together with OT4, a young and innovative company from southern Germany to deliver a new experience of creating custom orthotics for patients and orthopedic technicians alike.

Custom orthotics: The Service

OT4 is offering to their customers custom orthotics through 3D-Scanning with SHINING 3D´s EinScan Pro 2X Plus. Their 3D digital workflow covers engineering, modelling, printing service and everything in between. If necessary, the team also drives to the medical supply store and medical workshops to scan on-site.

Custom orthotics: The Workflow

Previously, the imprints for the custom orthotics were made manually with plaster bandages taken directly on the patient´s skin surface. With the new digital method of 3D-scanning, the imprints can be captured with a high level of detail.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

Custom orthotics: Advantages

The advantages of a digitized workflow are manifold. Compared to the old method of taking the impression for custom orthotics through applying plaster bandages, capturing the patient´s data via 3D-scanning is much faster and more hygienic through contactless data capturing. Additionally by using the digital way of data acquisition, a significant amount of trash (plaster bandages) and patient´s stress are reduced simultaneously.

The workflow of creating custom orthotics through 3D-scanning is very simple

The patient arrives at the orthopedic workshop with the doctor´s prescription

The diagnosis is used to create a treatment plan

3D-Scan is collected

The captured data is transferred to OT4

OT4 models the required splint digitally and manufactures the device with a 3D-Printer

In a short period of time, the custom orthotic splint can be delivered to the patient

Custom orthotics: Why to choose EinScan

OT4 has chosen the EinScan Pro 2X Plus as their companion to create custom orthotics due to the high resolution full-color 3D data the Scanner is able to deliver. Being capable of extracting all the necessary information to create medical aids much more efficient than plaster bandages, it is the ideal tool for them to deliver high-quality products to their customers. The excellent results powering the construction of optimal orthotics in combination with the incredible price-performance ratio of EinScan have convinced OT4 to even become a distribution partner of SHINING 3D and to offer trainings and workshops to medical staff.

About OT4

Founded in April 2018, Munich-based orthopedics company OT4 is specialized in the production of 3D-printed custom orthotics. Since then they have completed more than 1000 patient services and experiencing constant growth through championing the latest technology in their profession.

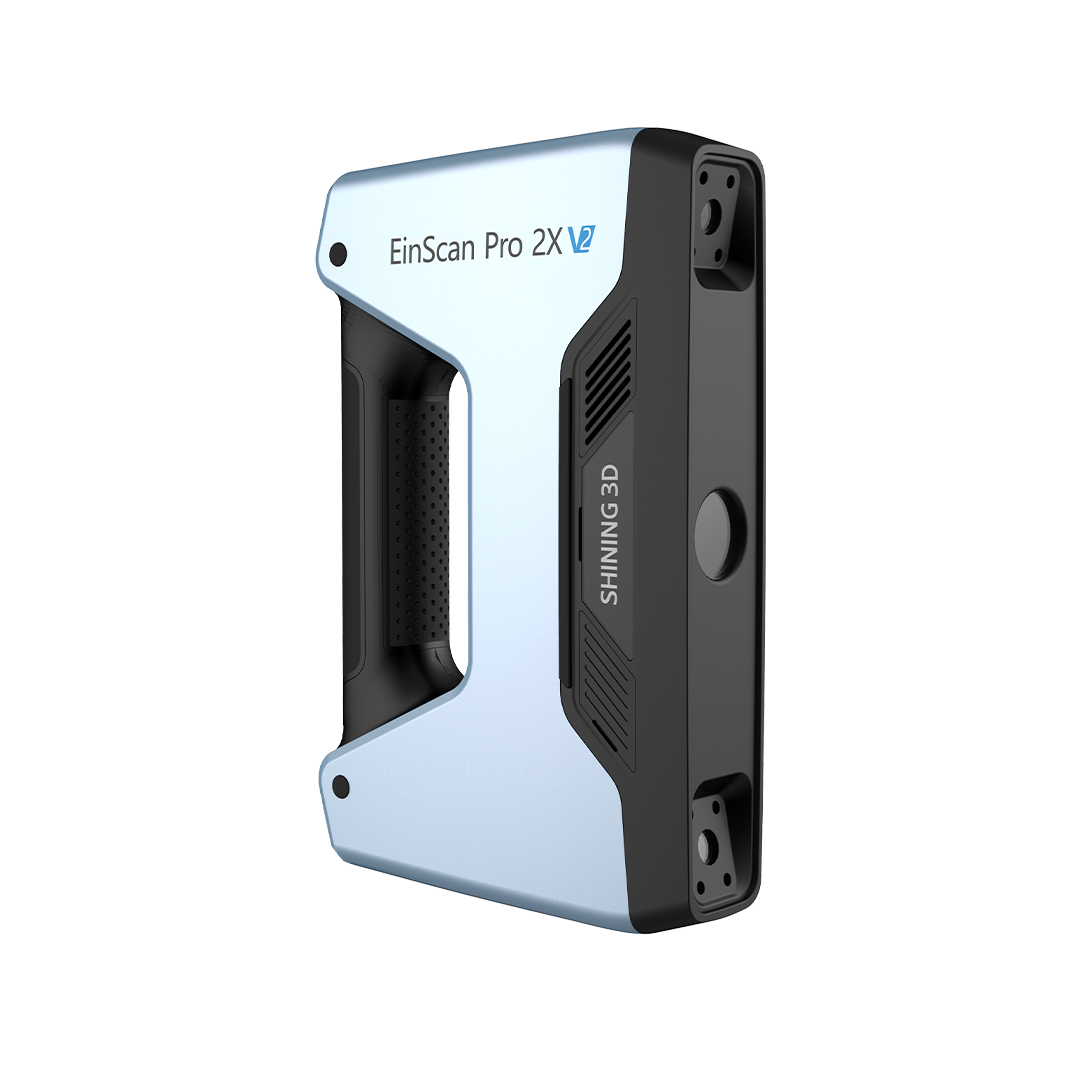

EinScan Pro 2X V2

The EinScan Pro 2X V2 is a portable, versatile 3D scanner offering high-speed scanning, high accuracy, and the ability to capture fine details. Ideal for professionals in design, manufacturing and digital archiving.

-

Impressive High Resolution

-

Flexibility for Handheld and Fixed Scanning

-

Modular Design for Multi-function

-

High Accuracy for High-Quality 3D Modeling