Summer is always a good time for the beach vacation. But still, unfortunate things can happen during the happy time. My friend accidentally broke her favorite sunglasses during the trip. Her glasses were a special gift and meant a lot to her. This certainly brought shadow to our trip. While all my other friends were trying to comfort her, as an engineer, I decided to use technology to bring back the broken glasses as well as her smile.

With examination, I found that the broken piece was the center connection part which could be separated and was a mirror part of the complete half. This means I could scan the intact half, do a reverse engineering to rebuild half of the part then mirror it to acquire a complete model. With the digital model in hand, I can 3D print the part using an FDM printer or SLS printer to bring it from virtual to reality.

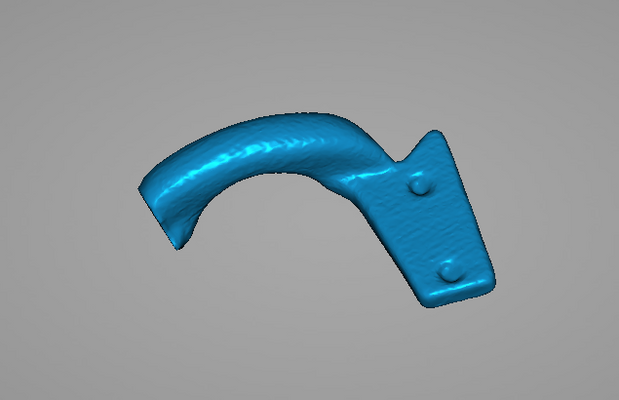

Since it was a reflective metal piece, which required to spray before scanning. I used EinScan-SP desktop scanner to capture the detail of the part accurately, despite the thinnest area of this part was only 1 mm. The scanned data could be meshed into a watertight STL model for editing.

Getting a mesh model was just the first step. The next step was to rebuild a more accurate CAD model. Because during the process of manufacturing, scanning and meshing, the error can be accumulated. By doing reverse engineering, an accurate CAD model could be reconstructed based on scanned data and engineering intent.

To do so, open the STL. file in Solid Edge. In Reverse Engineering tab, we could use automatic identify regions function to divide different feature regions and fit different feature to reconstruct the piece. The major steps were as the following.

Finally, we got a model ready for print. To make sure it fits, I printed it by Einstart-C desktop 3D printer firstly to test. After adjusting the size, I printed the part with steel and painted it gold. Voila, we bring the sunglasses back to life again; surely, her smile is also back!

DEU

DEU