.jpg?width=4608&height=3072&name=retouch_2025051413194198%20(1).jpg)

CASE STUDIES

Published on Jun. 23rd 2025

Calipers to Point Clouds, Babylon Engineering Turbocharged Auto Part Production with 3D Scanners

Once relying on traditional tools like vernier calipers and tape measures, Babylon Engineering has transformed its production workflow by adopting high-accuracy 3D scanning technology.

Once relying on traditional tools like vernier calipers and tape measures, Babylon Engineering has transformed its production workflow by adopting high-accuracy 3D scanning technology. What began as a small-scale workshop focusing on replacement parts for vintage vehicles has evolved into a high-tech reverse engineering workshop to support more business, thanks to the integration of SHINING 3D's scanning systems (first the EinScan HX and later the FreeScan Trak Nova).

About Babylon Engineering

Babylon Engineering is a precision engineering company based in Australia, specializing in 3D printing, reverse engineering, CAD design, and prototype development. Whether it’s a one-off custom component or large-scale production, the company delivers high-quality, durable, and cost-effective solutions across various industries, including automotive, manufacturing, food and beverage, and industrial design.

Coupe rear arm rests made by Babylon Engineering

The Manual Days: Measuring by Hand

In the early days, Babylon Engineering designed custom car parts the old-fashioned way—manually measuring warped and damaged originals with hand tools. Designers would draw contours by eye using CAD software, struggling to recreate precise geometry, especially for interior car parts with complex curvatures. This manual workflow was time-consuming and prone to inaccuracies. It was tough to get the contours in the right shape. They usually spent weeks trying to get it right.

EinScan HX 3D Scanner Enters the Scene

That changed four years ago with the purchase of the SHINING 3D EinScan HX, a handheld blue laser 3D scanner. “It’s great for the small parts, product parts,” Saad (Babylon Engineering’s Founder & Mechanical Engineer) commented. Meanwhile, the blue laser technology offered superior accuracy and better performance on surfaces that are difficult for other scanners, such as shiny or dark materials. The team could capture every contour and every crevice with incredible accuracy. The scanner allowed them to import detailed mesh models directly into their design software, enabling faster and far more accurate reverse engineering. What used to take weeks could now be done in days.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

.png?width=779&height=584&name=3D%20scanning%20an%20auto%20part%20with%20EinScan%20HX(1).png)

3D scanning an auto part with EinScan HX

Scaling Up with the FreeScan Trak Nova

As their capabilities grew, so did customer demands. Babylon Engineering soon expanded its scope to larger-scale projects. They adopted the FreeScan Trak Nova, a wireless, marker-free 3D dynamic tracking and scanning system. Compared to the EinScan HX, the FreeScan Trak Nova offers greater flexibility with its wireless operation and wider scanning range, eliminating the need for markers and enabling faster setup times. The Nova opened new doors: scanning full automobiles within a few minutes, and larger product parts with ease.

-1.webp?width=2000&height=1047&name=retouch_2025051413194539%20(1)-1.webp)

-1.webp?width=2000&height=1047&name=retouch_2025051413155635%20(1)-1.webp)

Saad is scanning the whole car body with FreeScan Trak Nova (left), checking the scanned data (right)

For Saad, SHINING 3D stood out not only because of the hardware but also because of the exceptional customer support and robust software integration. “It’s software marries well with the hardware. Even large files are processed smoothly with minimal errors,” he notes. “It’s fast, agile, and accurate.”

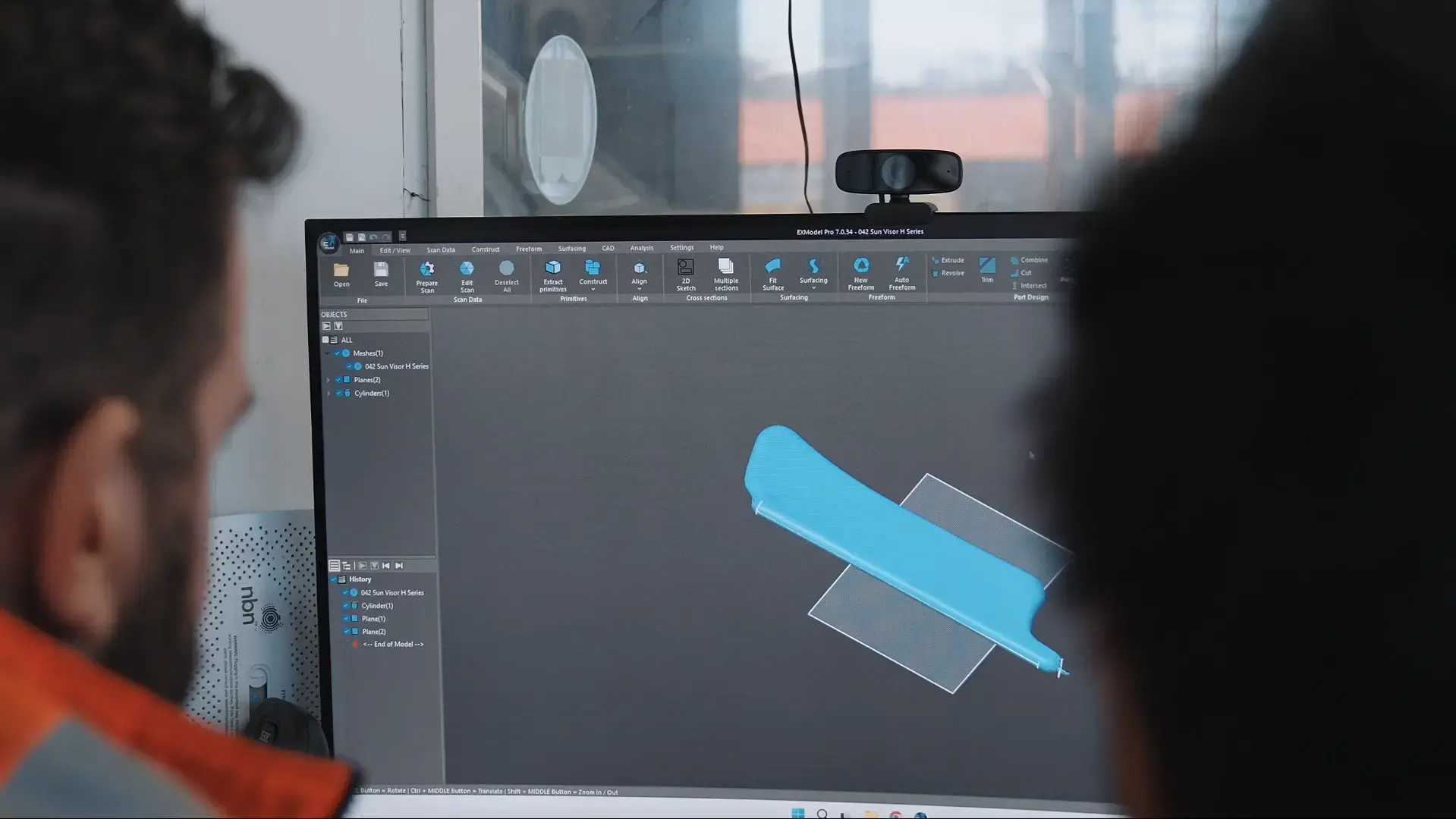

Data Processing and reverse engineering in EXModel

What started with tape measures and hand-drawn CAD files has turned into a streamlined, high-precision workflow that saves time, improves accuracy, and opens the door to entirely new types of work. With the EinScan HX improving accuracy for small and complex parts, and the FreeScan Trak Nova enabling efficient scanning of larger-scale objects, Babylon Engineering has streamlined its workflows and expanded its capabilities. Scanners have allowed them to take on more diverse and technically demanding projects with greater confidence and efficiency.

If you're looking to streamline reverse engineering, speed up prototyping, or improve measurement accuracy, explore what SHINING 3D’s solutions can do for your business. Reach out to learn more or request a demo tailored to your needs.

.png?width=2000&height=898&name=FreeScan%20Trak%20Nova%20(1).png)

FreeScan Trak Nova

- Flexible & Separable System

- Compact & Agile Dynamic Tracking

- Wireless & Lightweight Design

- Integrated Video Photogrammetry (VPG)