GUIDES/101

Published on 28th Oct. 2025

3 Stages of Wireless 3D Scanning — and How SHINING 3D Leads the Way

From early Wi-Fi modules to fully standalone systems, explore how wireless 3D scanning has evolved — and how SHINING 3D is defining the next frontier.

Why Wireless Is Becoming the Industry Trend

As 3D scanning moves from labs to real-world production and inspection sites, application scenarios have become more diverse and demanding. Users increasingly need lighter, more flexible devices that can operate freely in complex environments—factories, construction sites, or outdoor fields.

This evolution has naturally driven the industry toward wireless 3D scanning, enabling greater mobility and efficiency without compromising measurement reliability.

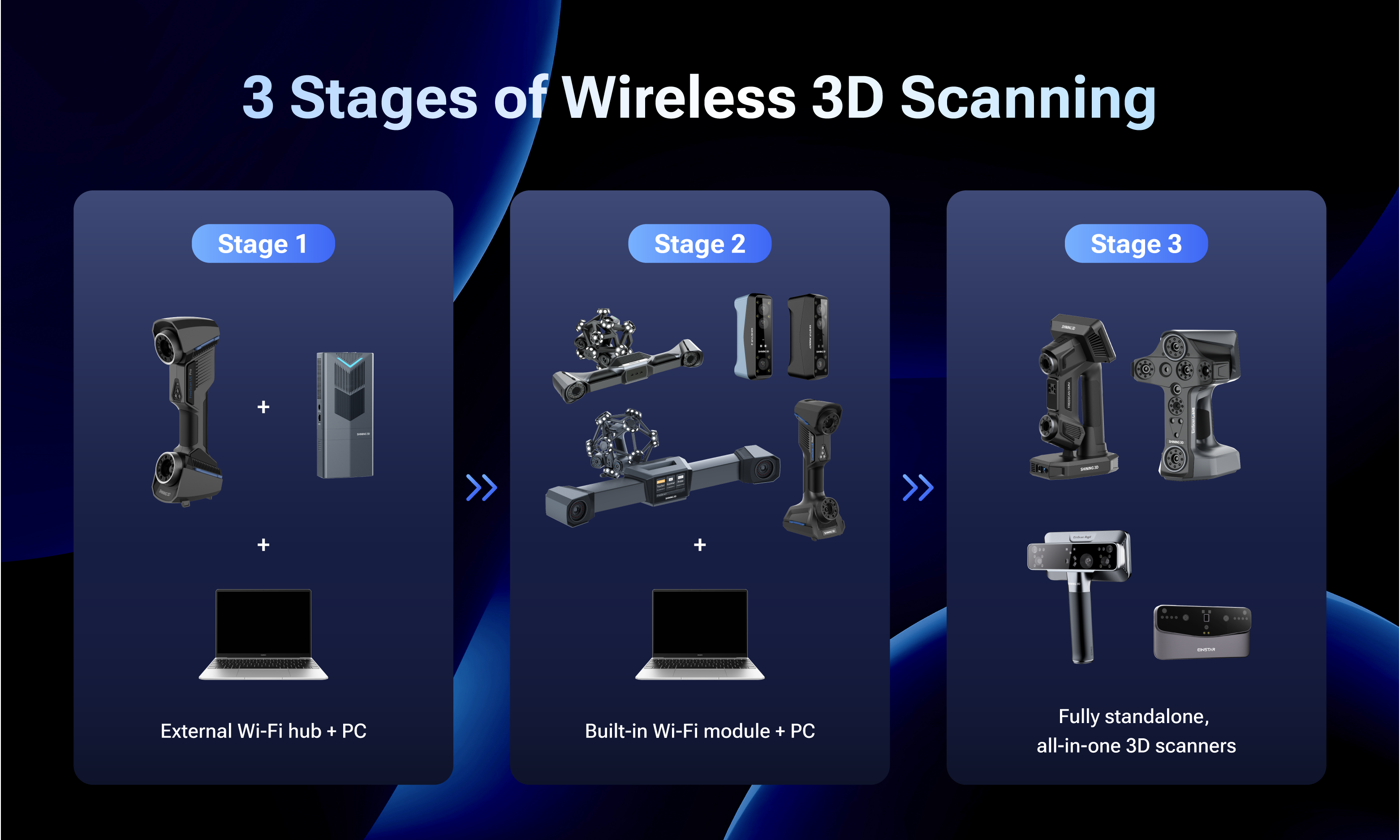

Three Technological Stages of Wireless 3D Scanning

The wireless 3D scanning landscape can be divided into three technological stages, each reflecting a different balance between mobility, integration, and processing capability. Across the industry, manufacturers occupy different stages, with SHINING 3D advancing the frontier through fully standalone solutions.

Stage 1: External Wi-Fi hub + PC

The earliest wireless systems relied on external Wi-Fi modules to transmit data from the scanner to a connected computer. While this setup reduced cable constraints and offered better operational flexibility compared with fully wired systems, scanners still depended on external power and a computer for processing.

In environments with complex or congested signals, data transmission could be less stable, affecting workflow efficiency.

Stage 2: Built-in Wi-Fi module + PC

To address the limitations of external Wi-Fi hubs, some manufacturers adopted wireless connectivity by attaching add-on Wi-Fi adapters, such as USB modules, to their scanners.

SHINING 3D took a more integrated approach, embedding the Wi-Fi module directly into the scanner. While a computer remained necessary for data processing, this design improved connection stability, simplified setup, and increased operational flexibility, particularly when scanning large components or working in more complex environments.

Stage 3: Fully standalone, all-in-one scanners

The third stage represents the current industry frontier. Scanners now integrate Wi-Fi and computing modules with built-in displays, allowing both scanning and data processing entirely on the device. This all-in-one design maximizes mobility and simplifies workflows without relying on external computers or power sources. Meeting users’ needs for lightweight, portable, and complete solutions.

SHINING 3D leads this stage with devices such as FreeScan Omni, EinScan Libre, EinScan Rigil and EINSTAR Vega, which exemplify fully standalone 3D scanning solutions.

Notably, FreeScan Omni introduces on-scanner inspection capability, the first of its kind in the industry, allowing operators to complete quality checks directly on the device — a milestone in industrial wireless 3D scanning.

Scanning a mold for quality control with FreeScan Omni

Scanning a mold for quality control with FreeScan Omni

SHINING 3D Leads the Wireless Era in 3D Scanning

Wireless 3D scanning is not a passing trend but a technological inevitability. As scanning tasks become more diverse and dynamic, wireless solutions offer unmatched flexibility, simplified workflows, and higher productivity compared with traditional wired setups.

Backed by deep expertise in optical metrology, hardware integration and intelligent software, SHINING 3D continues to push the boundaries of wireless 3D scanning. Its latest innovations represent the most advanced technology in the field, setting a new benchmark for truly mobile, intelligent, and efficient 3D measurement.

Wireless 3D Scanners of SHINING 3D