CASE STUDIES

Published on Jan. 25th 2022

FreeScan UE 3D Scanner Enables Rapid Reverse Engineering for Aircraft Engine MRO

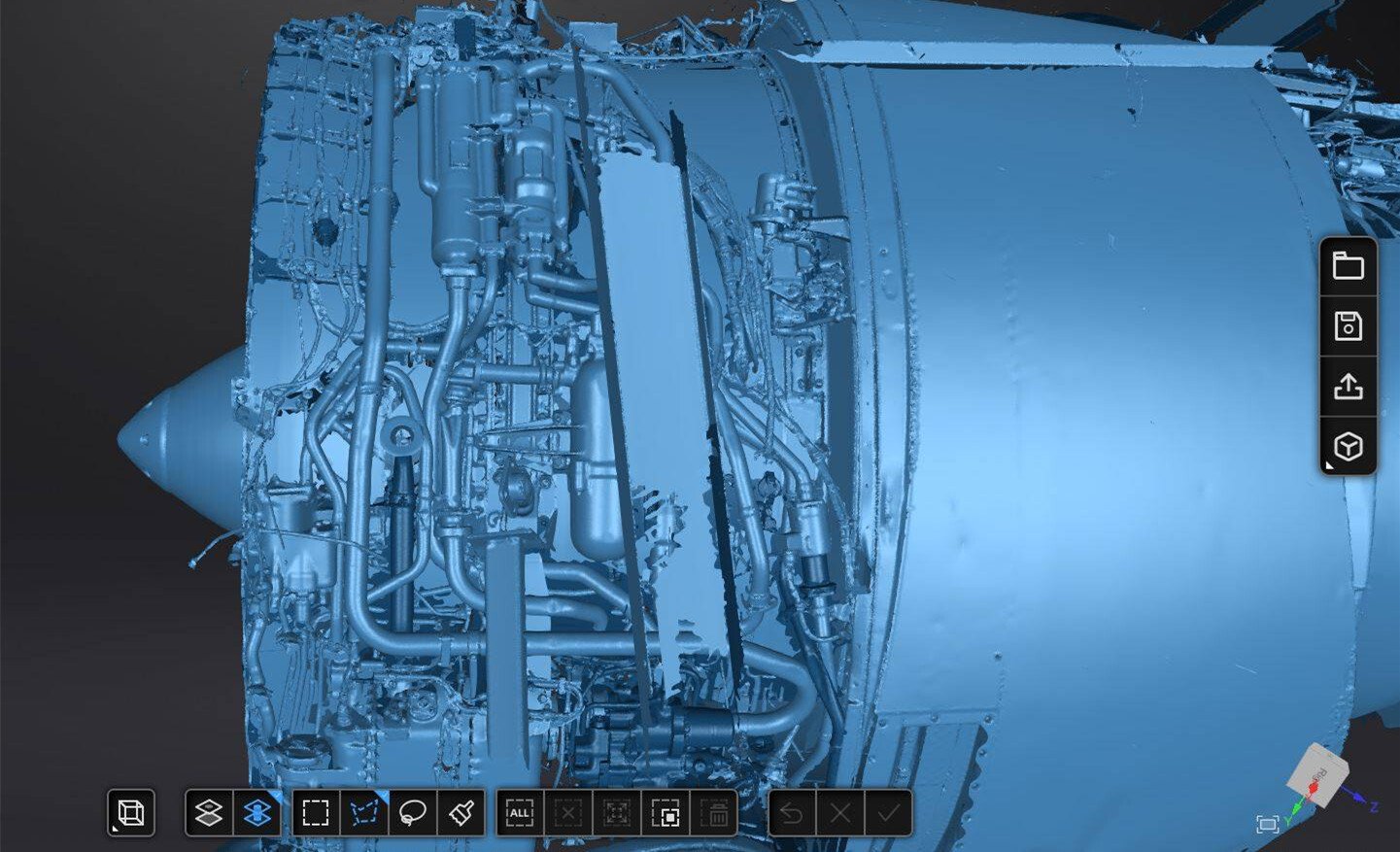

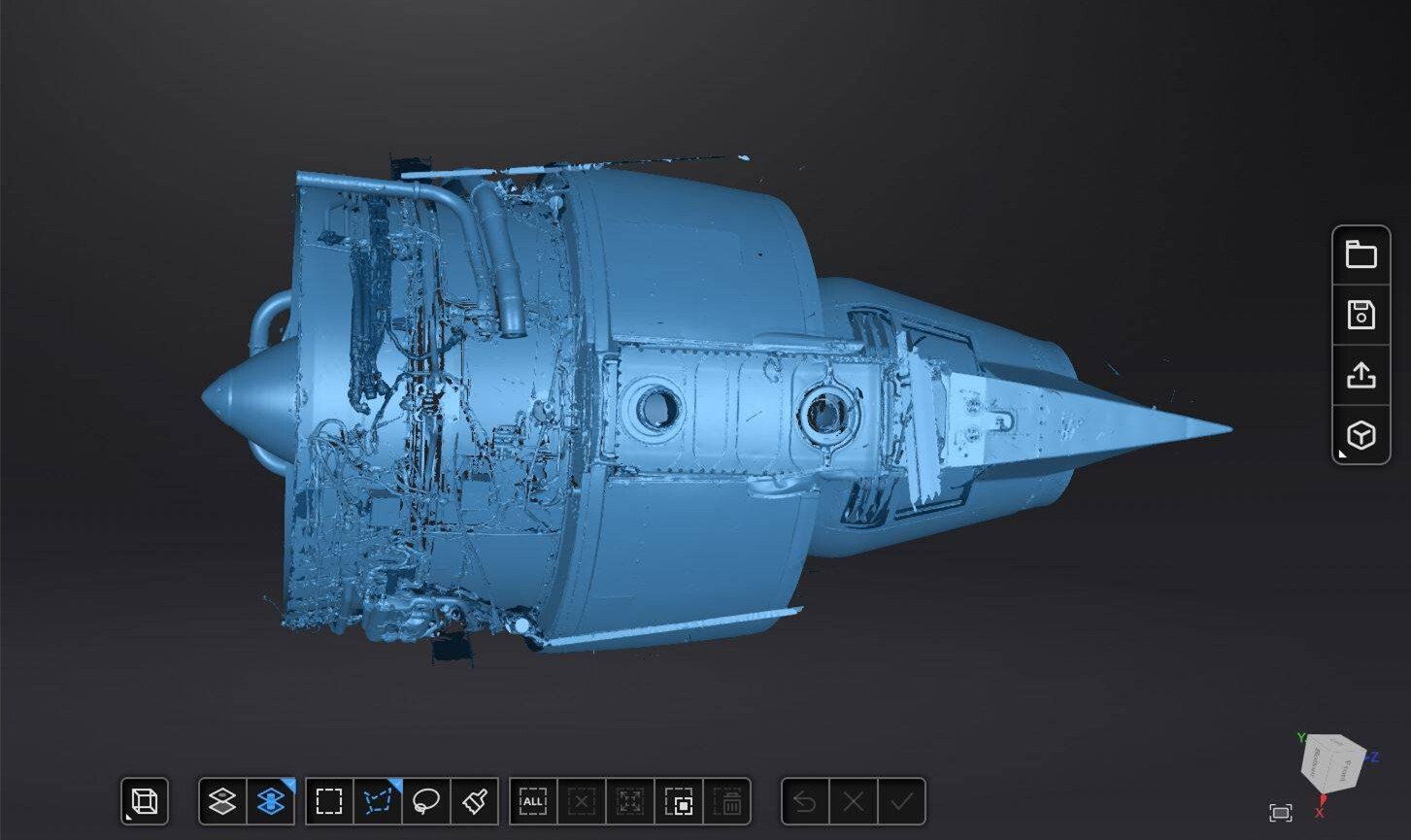

Learn how an aircraft MRO provider uses the SHINING 3D FreeScan UE laser scanner to capture complex, non-standard engine parts, creating digital blueprints for rapid, high-accuracy repair and fabrication.

For aircraft Maintenance, Repair, and Overhaul (MRO) teams, servicing complex systems like engines presents a unique and costly challenge. Beyond routine inspection, engineers are often tasked with repairing or replacing components that are non-standard, highly complex, or simply lack original CAD drawings.

An MRO service provider faced this exact bottleneck. Their core task involved servicing intricate aircraft engines. These engines are large-scale assemblies featuring numerous complex pipelines, free-form surfaces like turbine blades, and tightly integrated components.

The Bottleneck: Manufacturing Parts with No Blueprint

The team’s primary difficulty was the inability to source or fabricate replacement parts quickly and accurately.

-

Complex Geometry: Traditional measuring tools (calipers, gauges) were completely inadequate for capturing the free-form surfaces and complex routing of engine pipework and components.

-

No Digital Data: Many parts were non-standard or legacy, meaning no accurate 3D CAD models existed. This made creating precise manufacturing drawings for repairs or replacements a slow, error-prone process based on manual estimation.

-

Costly Delays: Every day spent trying to manually measure and model a part was another day the multi-million dollar engine was out of service, directly impacting operational schedules and costs.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

A Digital Workflow for Reverse Engineering

To eliminate this bottleneck, the MRO team adopted the SHINING 3D FreeScan UE handheld laser 3D scanner. The goal was to create a complete and accurate "digital 3D blueprint" of the entire engine assembly, enabling on-demand reverse engineering for any component.

The new digital workflow proceeds as follows:

- Large-Scale Data Capture: The portable FreeScan UE is brought directly to the engine. To ensure metrology-grade accuracy over the large volume, engineers first establish a global marker framework (often supplemented with photogrammetry) to lock in precision.

- High-Detail Scanning: The scanner rapidly captures the complete geometry of the engine at 1,350,000 points/second. This process accurately records the exact shape and position of all components, from complex pipelines to blade surfaces.

- Create the Digital Twin: The scan data is processed into a complete, high-precision 3D model. This model serves as the master "digital drawing" for the MRO team.

- Reverse Engineer & Fabricate: When a part needs repair or replacement, engineers can digitally "extract" it from the master 3D model. This data is then used to reverse-engineer a perfect, manufacturing-ready CAD file, which is sent directly for fabrication.

From MRO Bottleneck to On-Demand Manufacturing

By integrating the FreeScan UE, the MRO provider enhanced its maintenance capabilities, achieving significant and measurable improvements.

1. Creation of a "Digital 3D Blueprint"

The team now possesses a complete, accurate 3D model of the entire engine. Engineers can access this digital twin at any time to verify assembly information, check clearances, or plan maintenance procedures without needing physical access to the engine.

2. Rapid, On-Demand Reverse Engineering

The most significant result is the ability to fabricate custom parts on demand. The high-accuracy scan data (up to 0.02mm) provides a reliable foundation for reverse engineering, ensuring that newly manufactured parts fit perfectly the first time.

3. Elimination of Rework

The metrology-grade accuracy of the FreeScan UE eliminates the guesswork of manual measurement. This drastically reduces the risk of fabrication errors and costly rework, saving both time and materials.

4. Accelerated Maintenance Cycles

The entire process of repairing and replacing non-standard components has been dramatically accelerated. This efficiency gain accelerates the overall aircraft repair process, reducing downtime and enabling aircraft to be returned to service much more quickly.

SHINING 3D FreeScan UE proved to be a critical solution for this MRO provider. It empowered them to overcome the challenge of non-standard and legacy parts by creating their own digital inventory. This shift from a reactive, manual workflow to a proactive, digital one has fundamentally improved their efficiency, accuracy, and ability to keep aircraft flying safely.

FreeScan UE Pro

- Metrology-Grade High Accuracy

- Global Precision Control

- Multiple Scanning Modes