CASE STUDIES

Published on May. 5th 2025

FreeScan Trak Nova Helps Bracq Heritage Digitally Preserve and Restore Classic Mercedes-Benz Designs

Bracq Heritage, a classic car restoration workshop, is using FreeScan Trak Nova wireless tracking and scanning system to restore and repair vintage cars.

In a vintage workshop in Bordeaux, France, the past and future are meeting under one roof. At Bracq Heritage, a classic car restoration atelier run by Boris Bracq, the legacy of legendary automotive designer Paul Bracq—his father—lives on. Here, craftsmanship honed over decades is carefully blended with cutting-edge 3D scanning technology to bring history back to life.

About Bracq Heritage

Boris Bracq founded Bracq Heritage, a classic car restoration workshop dedicated to bringing back the legendary Mercedes models designed by his father, Paul Bracq—the iconic French designer behind many of Mercedes-Benz and Peugeot’s most memorable designs.

“I created this workshop to pay tribute to my father and his work,” Boris shares. “We call it a duty to remember.”

Bracq Heritage

Bracq Heritage

Bracq Heritage’s mission goes far beyond getting the engine to start again. Each restoration is a tribute to the original design philosophy—a process rooted in respect and authenticity. They strive to preserve every original part, every iconic curve, as much as possible.

Boris firmly believes that if you replace everything, then it’s no longer the same car. Preserving the soul is his core principle.

Yet achieving this is anything but easy. Parts for classic cars are often long out of production.

What Can 3D Scanning Technology Do for Classic Car Restoration?

Restoring these classics isn’t without challenges. Original parts are often discontinued, and the techniques used to shape bodywork in the 1950s were largely artisanal. In particular, complex forms such as curved body panels were once shaped entirely by hand over wooden bucks—templates carefully carved to mirror the final form.

“Today, we still build wooden bucks to shape metal panels just as they did in the 50s,” Boris explains. “But what we add is the power of digital tools. We 3D scan the car’s geometry, refine the shape in 3D software and then cut the bucks with CNC machines. The tradition stays intact, but the process becomes faster, more accurate, and more efficient.

This blend of old and new allows Bracq Heritage to honor the integrity of traditional coachbuilding while enhancing precision and repeatability—a critical advantage when working with irreplaceable models.

3D scanning interior of the car

3D scanning interior of the car

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

Why Did Bracq Heritage Choose FreeScan Trak Nova?

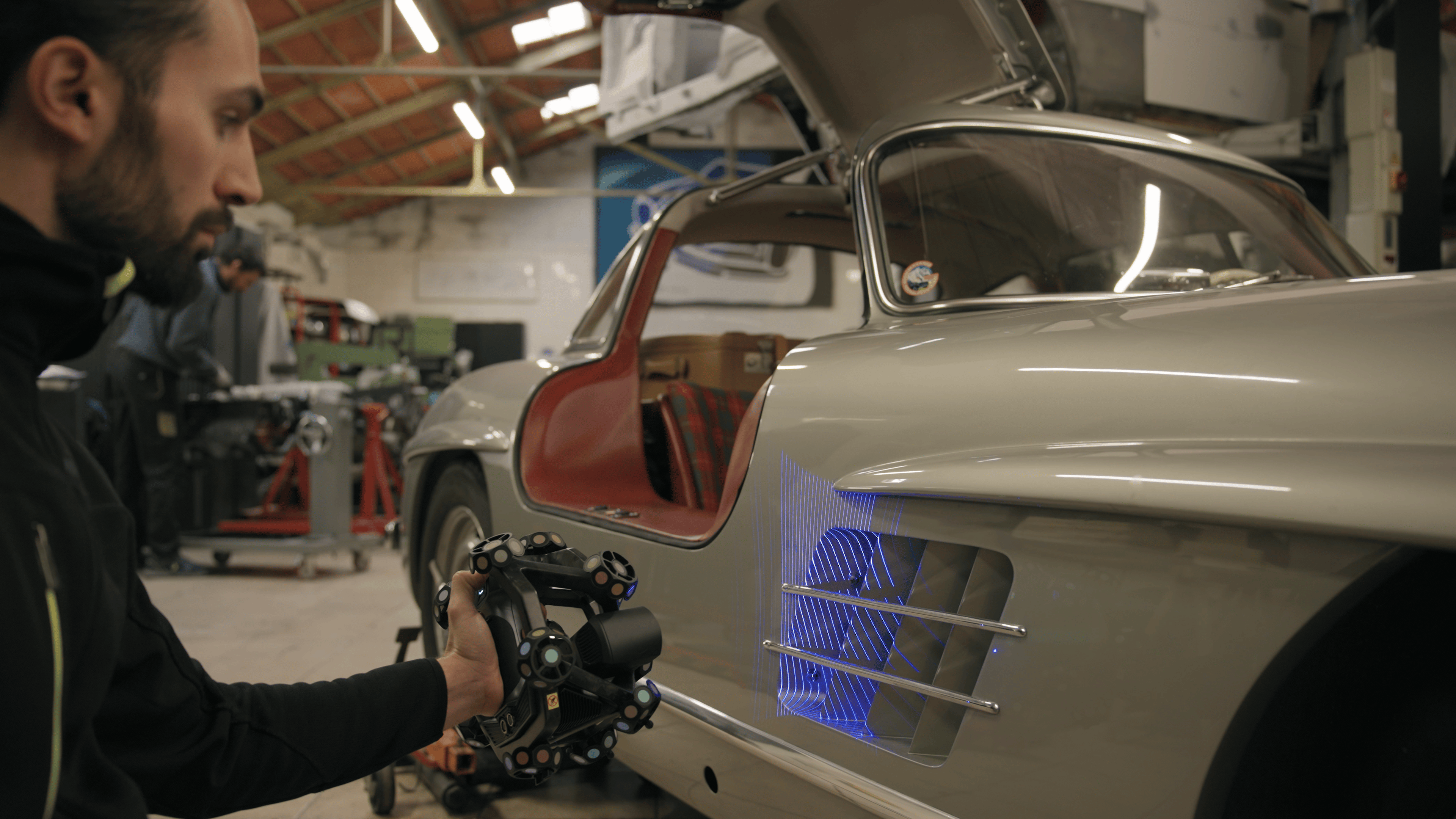

- Markerless and Fast 3D Scanning: In this project, markers were not allowed on the vehicle’s surface. FreeScan Trak Nova enables non-contact scanning without adhesives—preserving the car’s integrity. At the same time, it reduces the time spent sticking and removing markers.

- Portable and Workshop-Friendly: Weighing just about1 kg and powered wirelessly, the device is ideal for complex workshop environments with limited mobility.

- Seamless CADIntegration: Scan data flows directly into CAD platforms, where it’s refined and used to drive CNC machines, reverse-engineering efforts, or 3D printing—creating a direct path from physical object to digital model to finished part.

3D scanning with FreeScan Trak Nova

3D sanned data of a vintage car

3D sanned data of a vintage car

Conclusion

In Boris’s hands, and with the help of modern scanning technology, traditional coachbuilding doesn’t disappear—it evolves. The result is a rare harmony: century-old craftsmanship enhanced by 21st-century innovation—a restoration not just of cars but of stories, identity, and excellence.

.png?width=2000&height=898&name=FreeScan%20Trak%20Nova%20(1).png)

FreeScan Trak Nova

- Flexible & Separable System

- Compact & Agile Dynamic Tracking

- Wireless & Lightweight Design

- Integrated Video Photogrammetry (VPG)