CASE STUDIES

Published on Dec. 11th 2025

High-Accuracy 3D Scanning for Automotive Sheet-Metal Parts

Discover how Liuzhou Yinrui Automotive leverages high-accuracy 3D scanning to streamline sheet-metal part inspections, reduce development costs, and accelerate new vehicle model launches.

Today, high-accuracy 3D scanning technology is rapidly replacing traditional gauges thanks to its versatility. For automotive sheet-metal parts, it enables fast, full-dimension inspections while significantly reducing gauge development costs and shortening the overall development cycle for new vehicle models.

This case study explores how Liuzhou Yinrui Automotive Co., Ltd., a leading automotive sheet-metal manufacturer, has implemented high-precision 3D scanning in its production workflow and the value it has delivered. Yinrui specializes in the production and sale of automotive components and serves as a supplier to major OEMs.

High-Efficiency 3D Inspection for Automotive Sheet-Metal Parts

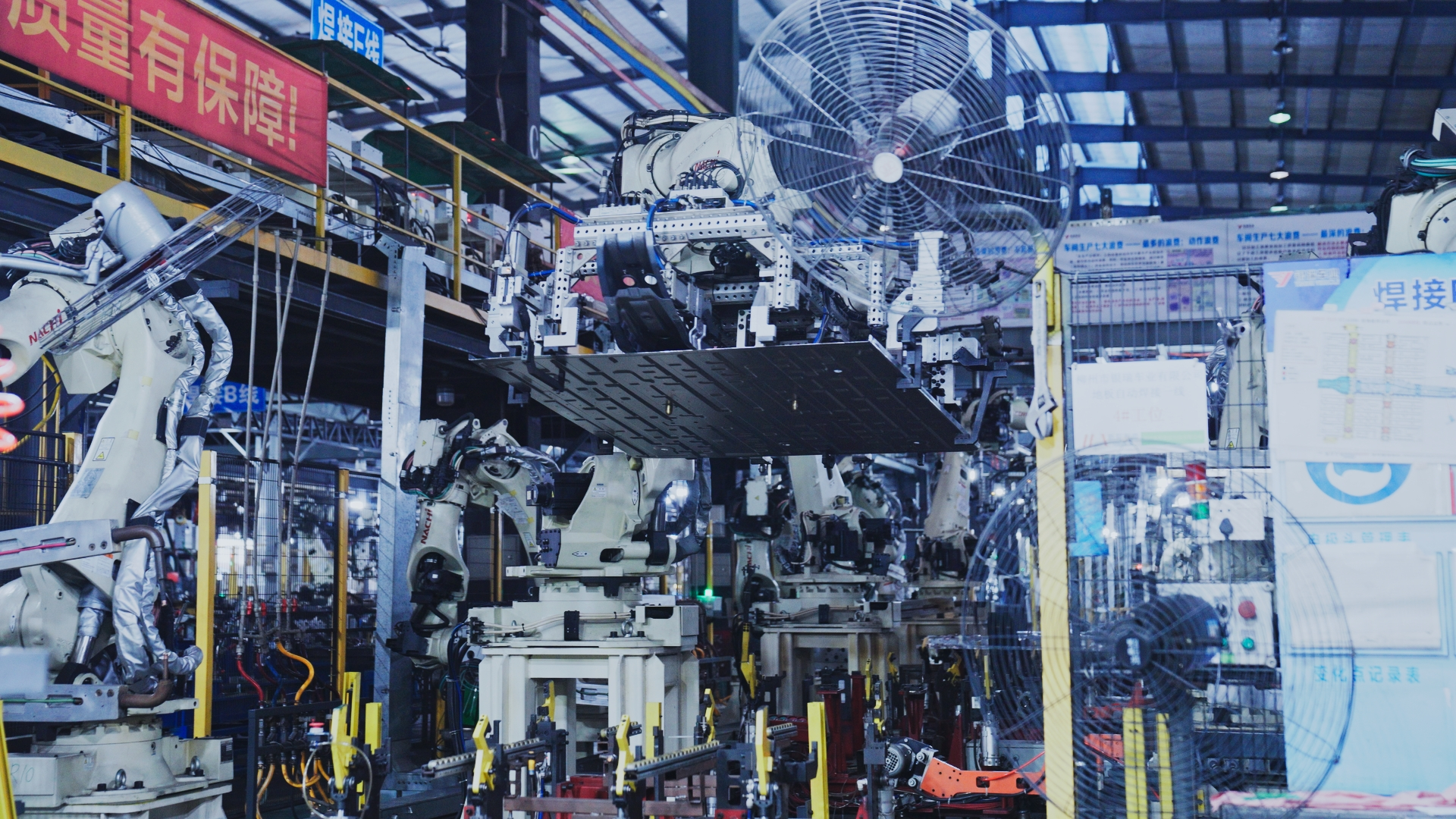

Inside the company’s manufacturing workshop, rows of high-speed industrial welding robots highlight the pace and precision required in modern automotive production.

High-speed industrial welding robots

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

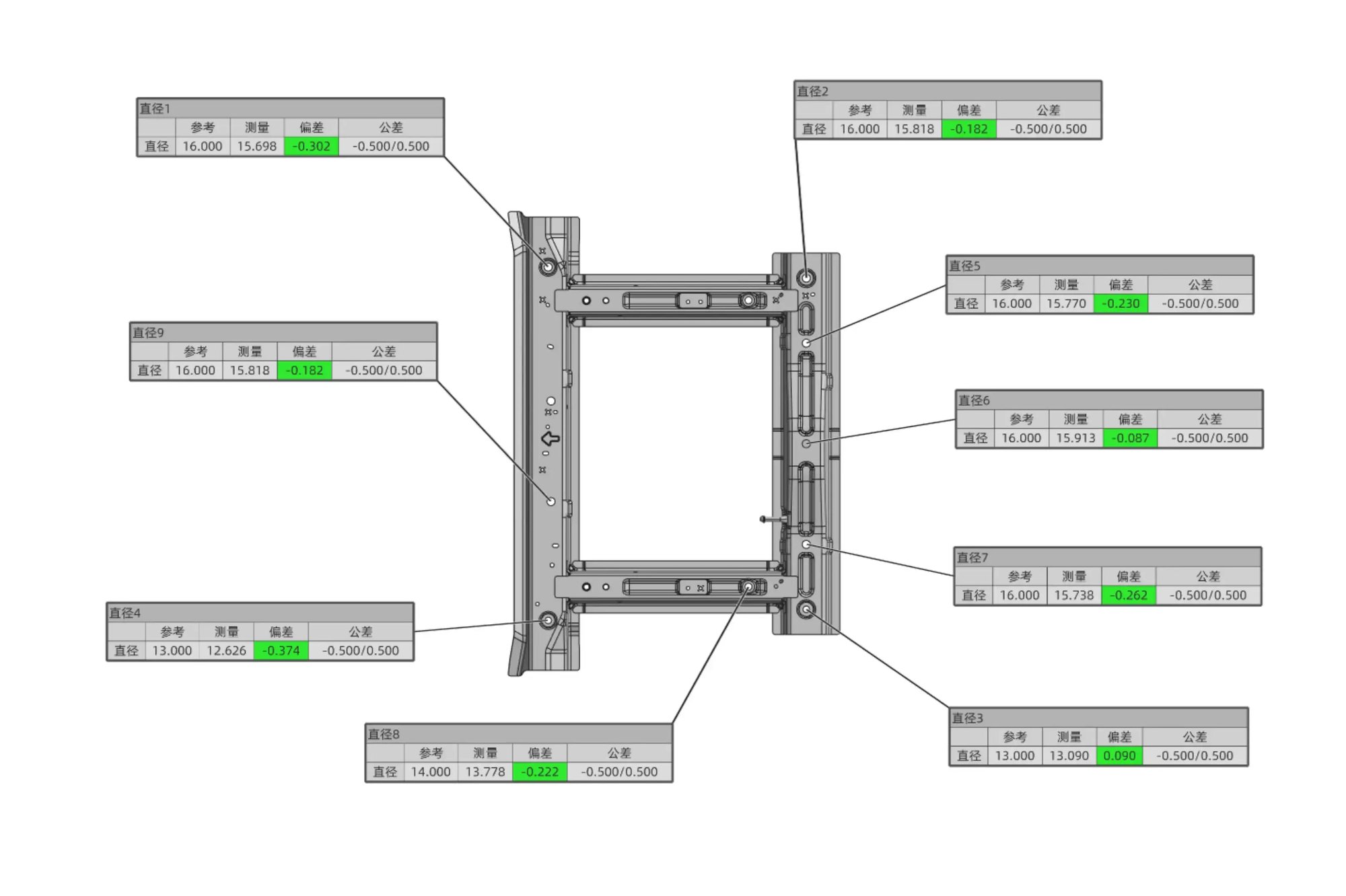

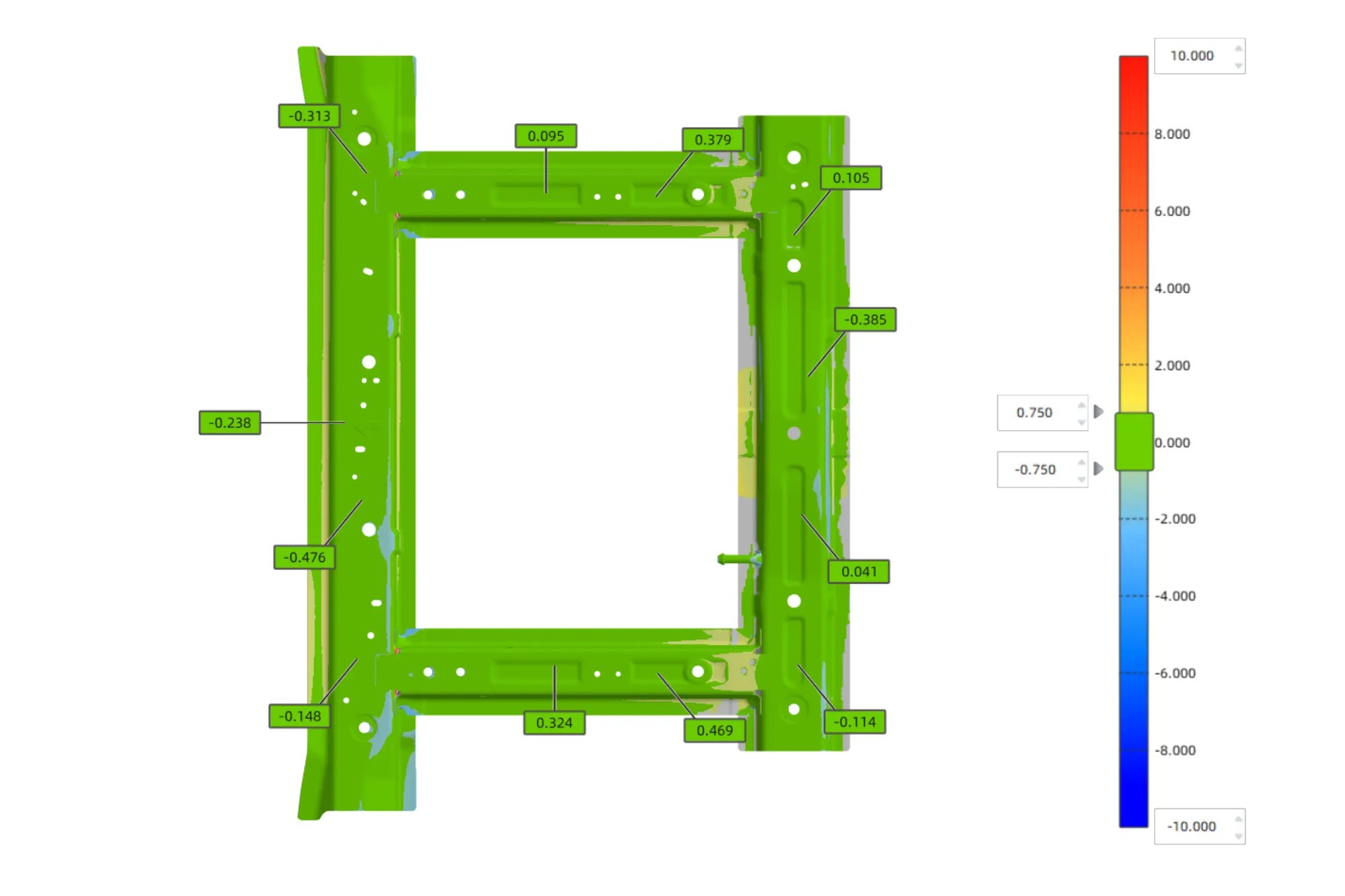

Engineers use the FreeScan Trak Nova to rapidly capture complete 3D datasets of sheet-metal components. Real-time meshing capability streamlines the inspection workflow.

Capturing complete 3D datasets of sheet-metal components by FreeScan Trak Nova

Inspection Report

Reducing Costs and Increasing Efficiency to Strengthen Competitiveness

One of the core advantages of replacing gauges with high-precision 3D scanners is the elimination of long gauge-development lead times. Traditional gauges typically require 1.5 to 2 months to design and build. A 3D scanner, however, can be deployed immediately. In the race to launch new vehicle models, this time savings directly translates to a significant competitive edge.

In addition, 3D scanners provide non-contact measurement and can handle a wide variety of part shapes and sizes. Traditional gauges are one tool per part, meaning every new component requires new gauge development and fabrication, driving up costs.

“Compared with traditional gauges, one of the biggest advantages of 3D scanners is saving the entire gauge development cycle. This can cut at least one-third of the project timeline. Gauge costs are extremely high, and some parts require inspections on both sides, which could even mean developing two sets of gauges. With a 3D scanner, every surface can be captured.”

— Mr. Zeng, Head of Quality Department

Liuzhou Yinrui Automotive Co., Ltd.

Cost reduction and efficiency enhancement are central drivers in the evolution of high-precision 3D scanning technology. SHINING 3D will continue advancing industrial 3D measurement solutions, empowering more automotive manufacturers and helping the industry reach new benchmarks in quality inspection.

.png?width=2000&height=898&name=FreeScan%20Trak%20Nova%20(1).png)

FreeScan Trak Nova

FreeScan Trak Nova is built to meet the diverse needs of industries requiring accurate and efficient large-scale measurements with extreme portability, productivity and versatility.

- Flexible & Separable System

- Compact & Agile Dynamic Tracking

- Wireless & Lightweight Design

- Integrated Video Photogrammetry (VPG)