Taurovenator (the genus name meaning "bull hunter") was originally named Taurovenator violantei and described in 2016; the earliest description was based on a postorbital (temporal-region) bone specimen from the Huincul Formation in Argentina. The animal is classified among the large carcharodontosaurid theropods and shows morphological affinities and comparability with other South American giant predators such as Giganotosaurus and Mapusaurus. In recent years, ongoing fieldwork and research by multiple scholars and teams have significantly expanded our understanding of the species.

Dr. Fernando Novas and Prof. Marcelo Pablo Isasi are the principal participants in the research on Taurovenator. They are researchers at CONICET (the National Scientific and Technical Research Council of Argentina), and have an extensive record of collaboration and publications with colleagues at home and abroad on the paleobiota of Patagonia and other South American faunas — for example, research connected with the discovery of Kostensuchus atrox, a formidable crocodile from roughly 70 million years ago found in Patagonia.

%20and%20Prof.%20Marcelo%20Pablo%20Isasi%20(left).webp?width=1800&height=1200&name=Dr.%20Fernando%20Novas%20(right)%20and%20Prof.%20Marcelo%20Pablo%20Isasi%20(left).webp)

Dr. Fernando Novas (right) and Prof. Marcelo Pablo Isasi (left)

Complete skull of Kostensuchus atrox, measuring nearly 50 centimeters in length

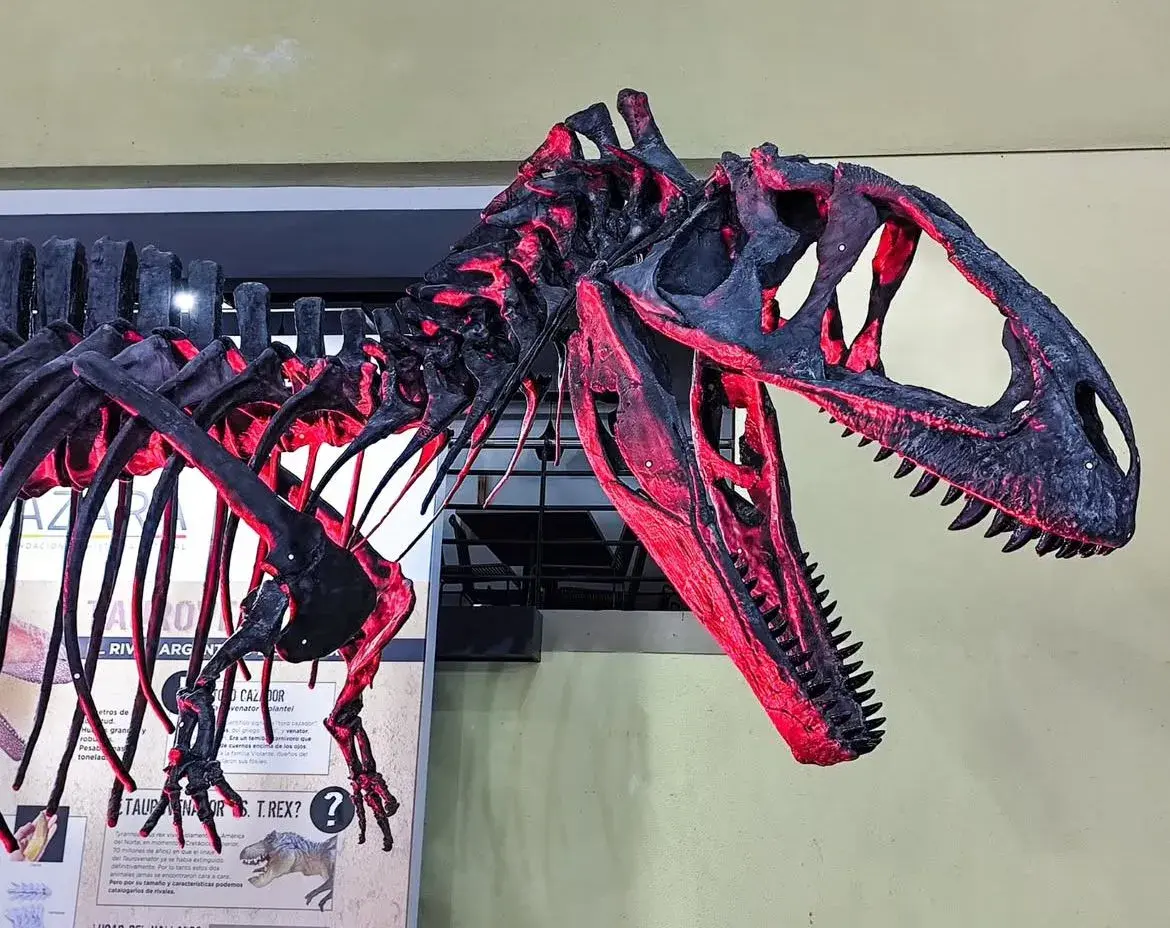

In the discovery and subsequent work on Taurovenator, local institutions, foundations, and companies have also taken part in model production and display — for example, Fundación Azara and the specialist 3D printing company Dryada.

Digital Workflow: How to Turn Fossils into Printable Models

In the Taurovenator reconstruction project, researchers adopted the following key steps, which are also the mainstream processes in current paleontological digitization work:

- Efficient 3D scanning and photogrammetry:

Researchers primarily used the SHINING 3D EinScan Pro HD 3D scanner together with photogrammetry to obtain 3D models. This method allows data collection without causing any damage to precious fossils. The EinScan Pro HD generates dense point clouds and produces high-resolution models. Its use of structured blue light ensures high accuracy, and its multifunctional design makes it suitable for objects of different sizes and materials, while also offering fast scanning speed. Combined with a large number of high-definition photographs taken with cameras, the dinosaur’s 3D model was faithfully reconstructed.

3D scanning with EinScan Pro HD, a structure light multi-functional 3D scanner

- Modeling and anatomical restoration:

In 3D software, researchers cleaned the scanned data (noise reduction, repairing broken parts), applied digital mirroring (to generate missing sides), and reconstructed the skeleton assembly on screen. This step required both the anatomical expertise of paleontologists (bone positioning, posture inference) and the modeling skills of digital engineers.

Reconstruction of Taurovenator

Reconstruction of Taurovenator

%20and%20Prof.%20Marcelo%20Pablo%20Isasi%20(left).webp?width=1800&height=1200&name=Dr.%20Fernando%20Novas%20(right)%20and%20Prof.%20Marcelo%20Pablo%20Isasi%20(left).webp)