Background:

SHINING 3D received a request from an auto heat exchange system manufacturer to inspect the quality deviation of the auto radiator water room and detect potential problems. Then modify the structure of the product based on test results.

FreeScan X5 handheld laser 3D scanner:

-Extra portable, 3D laser scanner weighting only 0.95kg;

-Precision as high as 0.030mm (30 microns), as per German’s VDI/VDE2634 standards;

-High speed scanning: 350,000 times/second

-Fast scanning and easy operation

-Capable of measuring large objects with stable performance;

-Limitless 3D scanning, without size limitations, materials and color of the object.

Solution:

Following the client’s requirements and the nature and features of the objects to inspect, SHINING 3D engineers opted for the use of the FreeScan X5 handheld laser scanner to quickly acquire the 3D data, analyze and use the data for reverse engineering, using Geomagic’s ® Control X and Design X software solutions.

Process

Working Process:

SHINING 3D engineers first communicated with the client to understand his inspection requirements, features of the object and desired output. Subsequently, SHINING 3D’s engineers recommended the use of the FreeScan X5 as the best technological fit for the application.

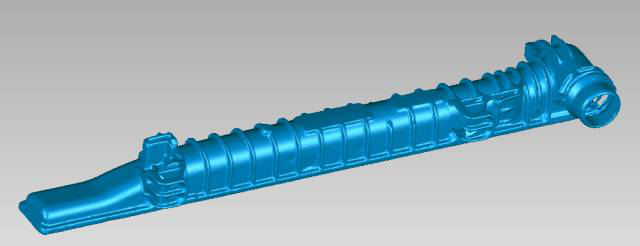

It took only 2 minutes to acquire the complete 3D data. Then the engineering team imported the 3D data into Geomagic’s software for its analysis, design and recommended modifications.

Advantages:

Captures complex surfaces more easily and faster than with the use of conventional inspection tools.

The conventional inspection method of inspection of an auto radiator water room involves the use of a 3D coordinate measuring machine (CMM) to obtain data by hard-probing. Due to the complexity of the surface of the object, it is difficult to identify the surface points to first program the CMM, making the process of taking the complete 3D data of the object a very difficult and a lengthy process.By contrast, the FreeScan X5 handheld laser 3D scanner can capture complex organic surfaces in a very short time, with speed and high accuracy.

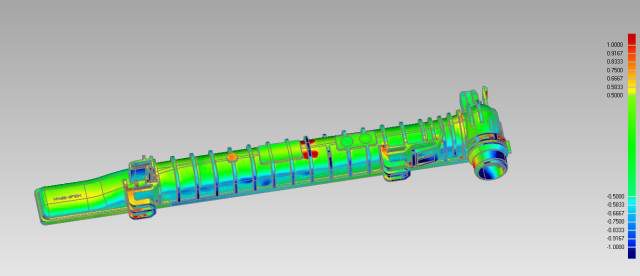

Generate the analysis report to identify the problem intuitively

The client was very satisfied with the level of details in the scanned object. The final analysis report was easy to understand, enabling the client to immediately identify design issues of the product and its build. The date also provided reliable and accurate information for the reverse engineering process.

ENG

ENG