A monocoque is a vehicle structure where the chassis is integral to the body. Every year the students of the Duale Hochschule Baden-Württemberg (Baden-Wurttemberg Cooperative State University) take part in the “Student Formula” race with a custom-built racing car. Universities from all over Europe present the racing cars they developed and built for the race and are evaluated by a jury in categories such as speed, technology, safety, marketing and, design. The competition gives students a direct application for engineering solutions that can involve everything from mechanical engineering to aerodynamics and metrology.

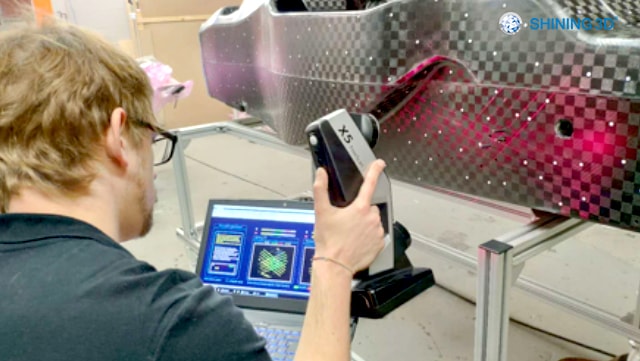

The students of the DHBW Engineering Stuttgart E.V. selected to scan this year’s monocoque with SHINING 3D’s handheld laser 3D scanner, the FreeScan X5. The metrology laser scanner is ideal in scanning large objects with the upmost accuracy (accuracy of up to 0.03mm) and precision (volumetric precision of up to 0.02 mm+0.08 mm/m). Using its intersecting lasers, it is able to scan objects that more common structured light scanners have a hard time with, including darker/black objects and reflective surfaces. The output data can be used for metrology level inspection and reverse engineering allowing for the correction of surfaces in the manufacturing process. Using the FreeScan X5 the 3D data was collected and later evaluated in order to compare vs data from last year’s version of the monocoque. The goal was to achieve better performance from last year’s version using the gathered information and analysing the scan data to get a better idea of the tolerances of the production process.

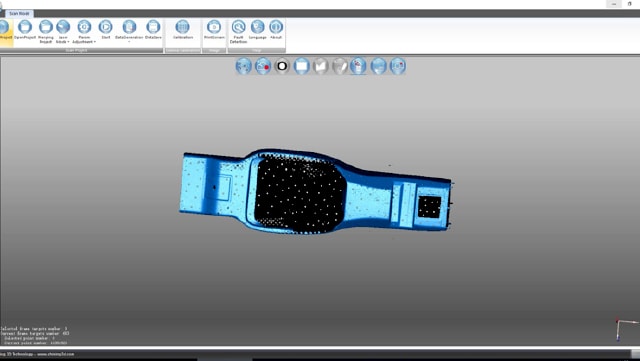

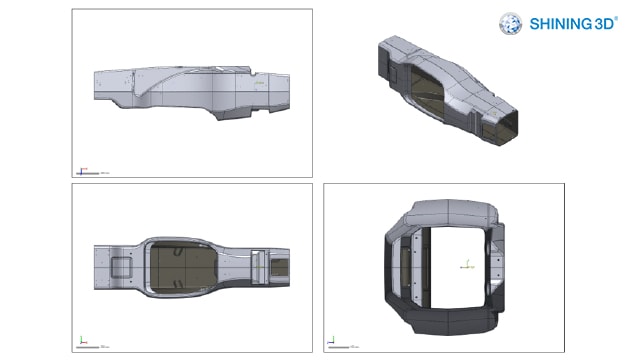

In order to be amongst the forerunners of the Student Formula competition, students must invest a lot of time and energy into this project year after year. To better investigate the tolerances that arise during the manufacturing process and to use the knowledge gained in coming years, the used monocoque was initially covered with markers and then scanned over its entire surface with the 3D scanner. This gives the students an understanding of how the vehicle compares to its original CAD model and allows for the inspection process to take place. The scan also allows the vehicle to be compared to previous vehicles used and most importantly provides a benchmark for future versions of the monocoque.

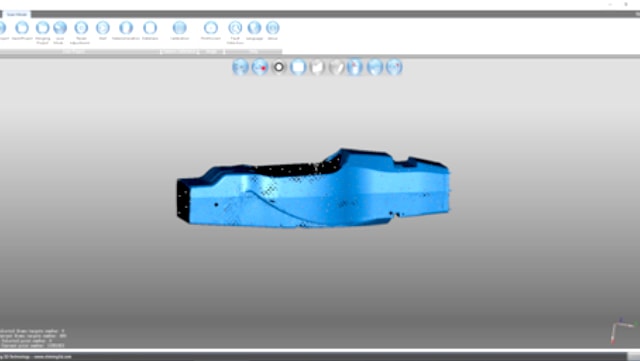

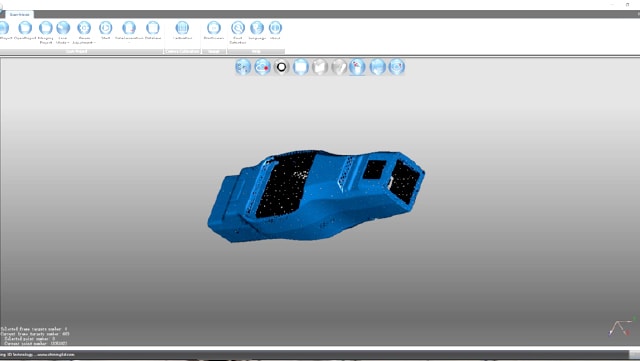

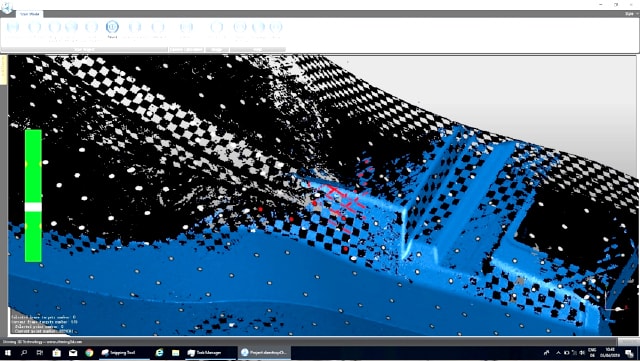

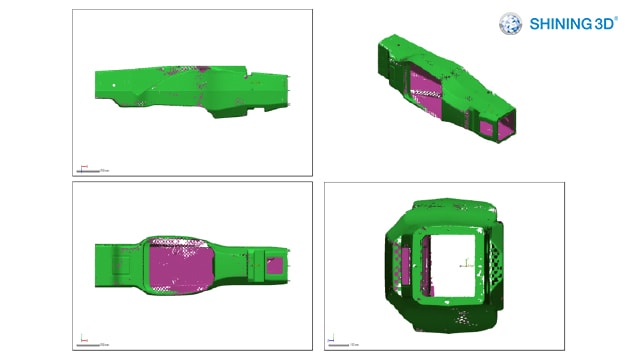

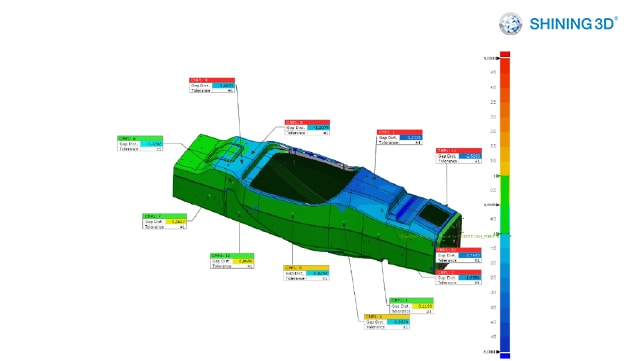

The scan process is relatively quick for such a large object. The markers are placed throughout the vehicle and used as a reference for the FreeScan. Once complete the students begin the scanning process using the handheld laser scanner. The entire vehicle is completed in one scan without needing to be pieced together manually. This saves the user a considerable amount of time as no manual alignment of the scan data is required and the heavy lifting is done by the software. The FreeScan’s software processes the image and creates a 3D model from the scan data which can be exported as a universal 3D file, an STL file also known as a meshed model. This meshed model is used by the students to demonstrate any deviations the vehicle has from its original design. The inspection report shows a CAD to part comparison in a helpful color map making it easy to understand the deviations.

Since important parts of the race car such as roll-bars are later attached to the holes on the monocoque, it was critically important to ascertain information about the accuracy of component fit. These small details are what sets apart modern engineering solutions to outdated traditional methods. With the FreeScan X5 the students were able to digitize their entire process and limit the errors that traditional measuring tools can fall victim to. If you’re looking for more information on how to modernize your 3D scan to CAD workflow or how to apply 3D scanning to your daily applications, reach out to us directly at sales@shining3d.com

Scanning Process:

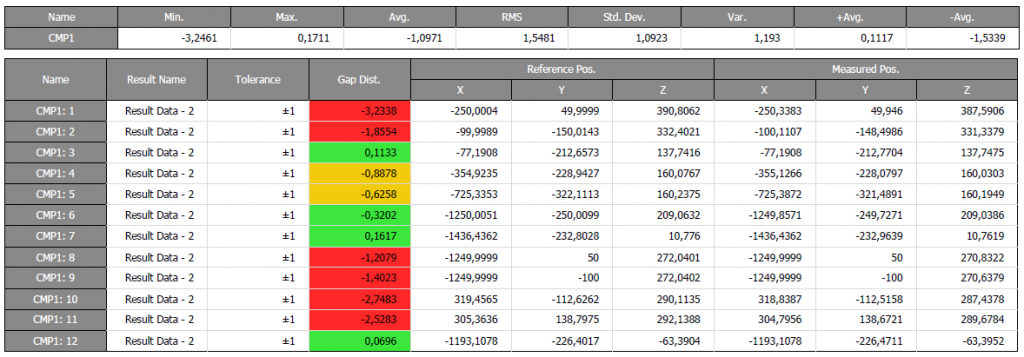

Measured Data:

Reference Data:

Comparison:

ENG

ENG