Background:

Bull, as a household socket brand, is well-known for their high-quality product. To ensure pre-delivery socket being qualified, Bull is looking for the assistance of 3D scanning technology in the production line to conduct spot test.

Introduction:

SHINING 3D’s metrology 3D scanner OptimScan-5M was applied in Bull socket’s quality control, capturing the 3D data of the samples for GD&T special.

About Bull:

Bull is a leading group corporation of electrical products dedicated to providing customers with comprehensive electrical connection solutions underpinned by innovative technologies, intelligent products and quality services. They have always kept our customers’ needs in mind and endeavored to provide hundreds of millions of families with a safe and comfortable environment for using electricity. They have also led the industrial upgrade and innovation, keeping abreast of the new electricity era featuring solutions for intelligent, comfortable and convenient electricity use.

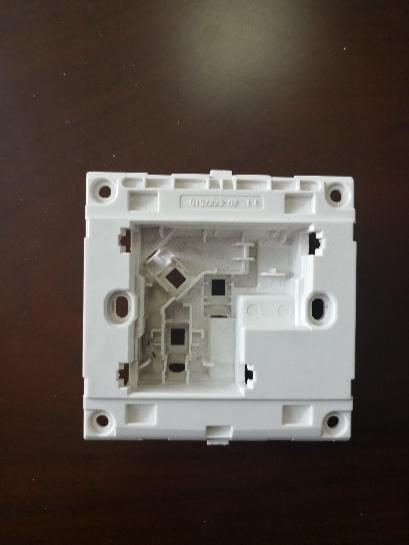

Spot test samples from production line:

Inspection Requirements: thickness of socket and parts’ assembly dimensions

Scanning Device: SHINING 3D OptimScan-5M Blue-Light Scanner

SHINING 3D OptimScan-5M Blue-Light Scanner

-Metrology 3D scanning system with controllable cost

-Features 5 mega-pixel industrial camera with precision up to 5µm

-Full-size scanning is able to conduct more than 100 dimension measurements (such as tiny size, curved surface silhouette and accessories aperture measurement, etc.), together with the inspection report.

Process:

Step 1:

Scan the samples.

Step 2:

Process the scanning data.

Step 3:

Use GD&T software to generate comparison report automatically.

Summary:

Due to the increasing labor cost, inevitable random human error and other limitations of traditional manual measurement, metrology 3D Scanning is able to conduct full-size inspection with faster scanning speed and high-accuracy 3D data to generate report automatically, which saves labor cost and improves the efficiency.

DEU

DEU