Over the years, new intelligent technologies such as high precision 3D scanning has been developing in improving the efficiency of train inspection and maintenance work. SHINING 3D recently cooperated with a domestic vehicle factory to 3D inspect a new bullet train by applying 3D digitizing technology, which ensured a safe trip for all the passengers.

Over the years, new intelligent technologies such as high precision 3D scanning has been developing in improving the efficiency of train inspection and maintenance work. SHINING 3D recently cooperated with a domestic vehicle factory to 3D inspect a new bullet train by applying 3D digitizing technology, which ensured a safe trip for all the passengers.

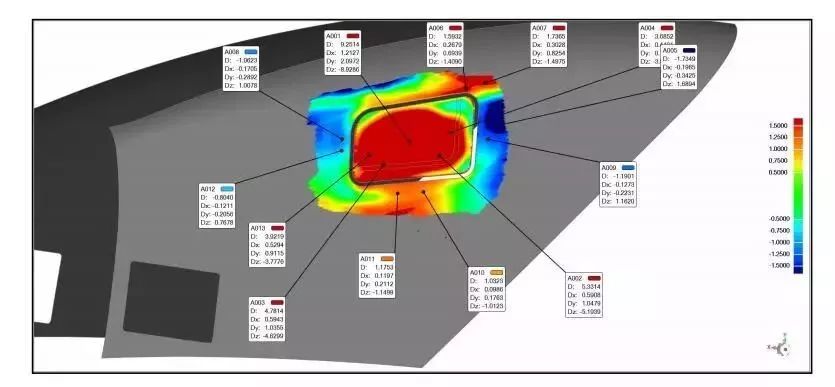

The scanning process was divided into three parts: post-installation scanning, glass scanning, and window frame scanning. After scanning the whole part including both the glass and window frame firstly, the staff disassembled and then scanned the glass and window frame respectively. Then the staff imported the data directly into Geomagic®Control software together with the original designed CAD data, creating an inspection report of the normal deviation by 3D comparison. According to the report, the R&D center rapidly found out the key parts affecting the glass deformation, thus assembling the window under the instructions to avoid manual errors.

In summary, FreeScan X5 took less than 30 minutes to scan two windows for six times , which saved a lot of time for the following precise assembly and testing. Also, because of the high-quality 3D data FreeScan X5 obtained, the staff was able to find the key parts affecting the service life of glass in a short time, thus making accurate and rapid adjustments.

ENG

ENG