Reverse Engineering Medical Implants with the OptimScan-5M

The world of medical implants is vast and continues to expand as the technology it is based on becomes more accessible and better understood. Customization for medical solutions is taking the industry at an alarming rate and 3D scanning and printing solutions are at the forefront of it all. 3D scanning can create accurate 3D models of various objects, tools, or body parts to give doctors a better understanding of treatment options. Having a full 3D model of a patient’s metal implant can help doctors through the treatment process in ways that were simply inaccessible before the technology was available. Through 3D scanning, we can reverse engineer and build accurate digital models of human metal implants.

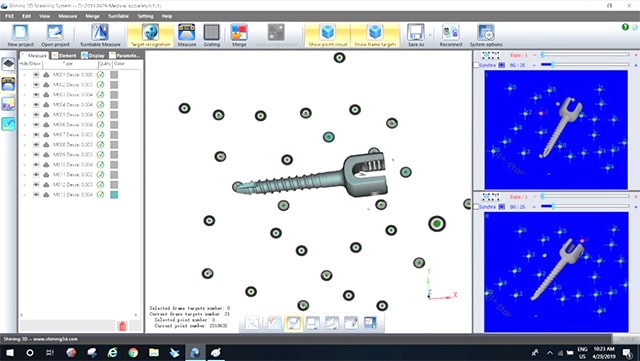

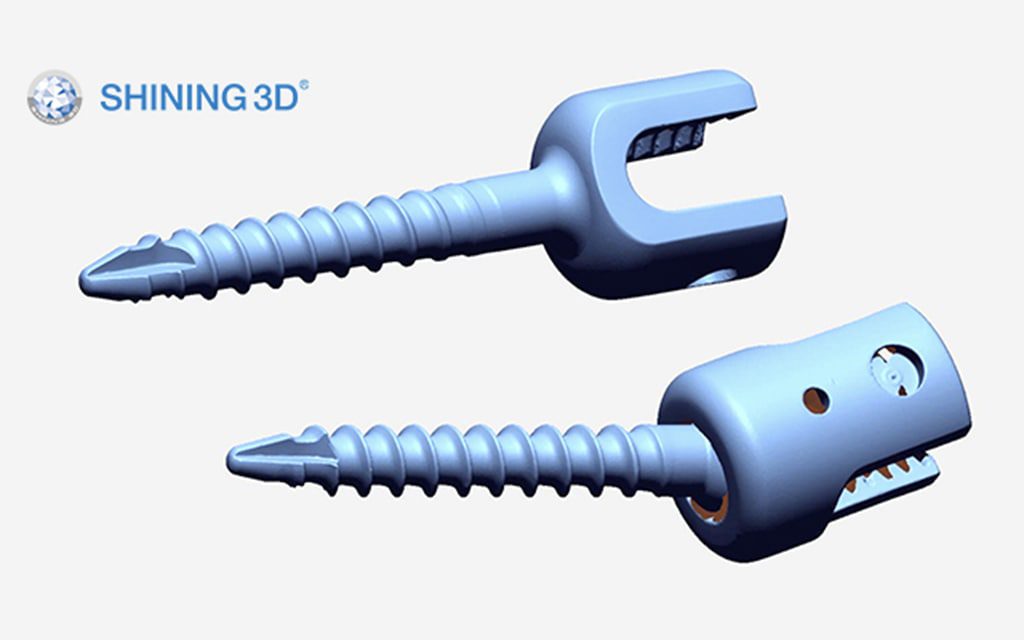

Many of the implants used today will be smaller in size which can present a challenge for certain 3D scanners. This is because a 3D scanner will only capture areas that it can see and smaller objects with tight areas can prove to be quite difficult. SHINING 3D’s OptimScan-5M has interchangeable fields of view allowing it to scan a wide range of objects with metrology grade precision. The smallest of these fields of view is 100x75mm which makes it perfect for capturing small scale data. The OptimScan-5M is Blue-light scanner equipped with a 5-megapixel camera. This allows the OptimScan to capture high resolution images of objects with up to 5 microns of accuracy. Its blue light reduces the digital noise that can be found with other white light scanners, making it the ideal scanner to scan small edges that need high resolution to be defined properly in 3D models.

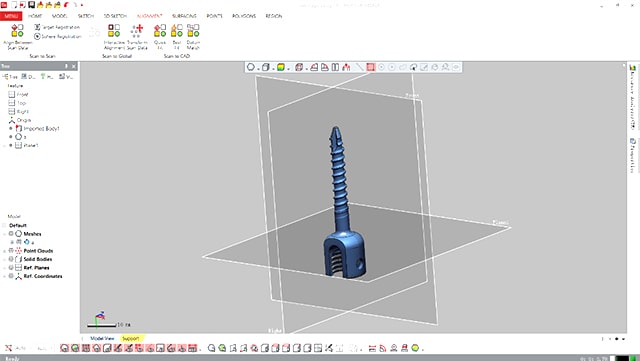

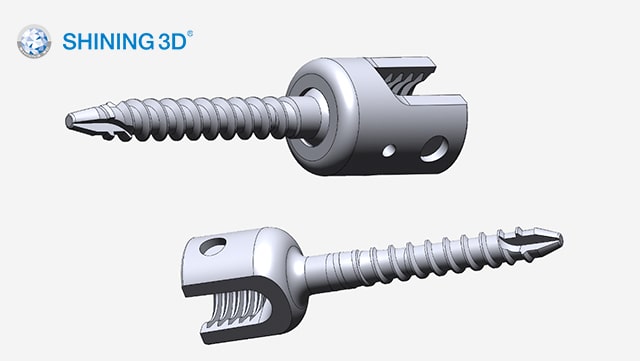

The OptimScan-5M takes individual images of the object similar to a standard digital camera. The software processes these images and stitches them together to form a complete 3D model. Each image takes roughly 1.5 second to capture, making the entire scan process extremely fast and efficient. Once the scan is completed the file can be exported in various formats, the most common one being STL files which are a universal file type used for 3D modeling, imaging, and 3D printing. The STL file can then be reverse engineered using CAD software giving doctors a usable model to use in treatment and in various software applications. With the model in hand doctors are able accurately analyze the treatment process of the implant.

Reverse Engineering

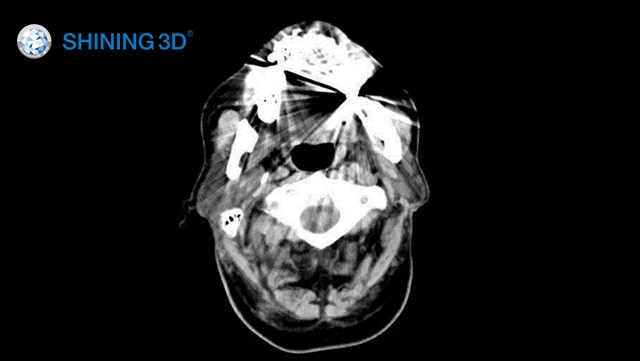

One of the main uses for the 3D model of the

implant is for proper imaging of the affected area. After the metal implants

are implanted, when doctors take CT scan of the area, the metal implants would obstruct

the image as shown in the picture below. The metal implant interferes with the

CT scan in a way that can make treatment extremely difficult and can overall

affect doctor’s diagnosis of the patient’s condition. The reverse engineered

digital model could compensate the result, to help doctors have better judgment

of what the actual area looks like and treat accordingly.

The metal implant also affects the dosage absorption rate of many treatments which can negatively affect patients in multiple ways. Doctors need an accurate model of the implant to properly evaluate each case. Using the reverse engineered 3D model and professional software solutions they can calculate how the metal implants affects the dosage and provide a more accurate diagnosis.

Customization continues to grow and vastly improve medical treatments. Personalized treatments are more readily available than ever before, and 3D Scanning and printing are at the forefront of these applications. As an industry leader in 3D digitalization and additive manufacturing, SHINING 3D continues to work together with industry professionals to provide cutting edge solutions. For more information on the various applications that 3D Scanning and Printing are revolutionizing please contact us at sales@shining3d.com

ENG

ENG